People with many different skills are needed to explore for oil and gas, drill new wells, maintain existing wells, and process natural gas. The largest group includes professional and related workers, accounting for about 23 percent of industry employment. Managerial, business, and financial workers account for about 21 percent of employment, while transportation and material moving workers make up about 12 percent, construction and extraction workers make up about 11 percent, and production workers also make up about 11 percent (table 1).

A petroleum geologist or a geophysicist, who is responsible for analyzing and interpreting the information gathered, usually heads exploration operations. Other geological specialists also may be involved in exploration activities, including paleontologists, who study fossil remains to locate oil; mineralogists, who study physical and chemical properties of mineral and rock samples; stratigraphers, who determine the rock layers most likely to contain oil and natural gas; and photogeologists, who examine and interpret aerial photographs of land surfaces.

Additionally, exploration parties may include surveyors and drafters, who assist in surveying and mapping activities. Some geologists and geophysicists work in district offices of oil companies or contract exploration firms, where they prepare and study geological maps and analyze seismic data. These scientists also may analyze samples from test drillings. Other workers involved in exploration are geophysical prospectors. They lead crews consisting of gravity and seismic prospecting observers, who operate and maintain electronic seismic equipment; scouts, who investigate the exploration, drilling and leasing activities of other companies to identify promising areas to explore and lease; and lease buyers, who make business arrangements to obtain the use of the land or mineral rights from their owners.

Petroleum engineers are responsible for planning and supervising the actual drilling operation, once a potential drill site has been located. These engineers develop and implement the most efficient recovery method in order to achieve maximum profitable recovery. They also plan and supervise well operation and maintenance.

Drilling superintendents serve as supervisors of drilling crews, overseeing one or more drilling rigs. Rotary drilling crews usually consist of four or five workers. Rotary drillers supervise the crew and operate machinery that controls drilling speed and pressure. Rotary-rig engine operators are in charge of engines that provide the power for drilling and hoisting. Second in charge, derrick operators work on small platforms high on rigs to help run pipe in and out of well holes and operate the pumps that circulate mud through the pipe. Rotary-driller helpers, also known as roughnecks, guide the lower ends of pipe to well openings and connect pipe joints and drill bits.

Though not necessarily part of the drilling crew, roustabouts, or general laborers, do general oilfield maintenance and construction work, such as cleaning tanks and building roads. Pumpers and their helpers operate and maintain motors, pumps, and other surface equipment that forces oil from wells and regulate the flow, according to a schedule established by petroleum engineers and production supervisors. In fields where oil flows under natural pressure and does not require pumping, switchers open and close valves to regulate the flow. Gaugers measure and record the flow, taking samples to check quality. Treaters test the oil for water and sediment and remove these impurities by opening a drain or using special equipment. In most fields, pumping, switching, gauging and treating operations are automatic.

Other skilled oilfield workers include oil well cementers, who mix and pump cement into the space between the casing and well walls to prevent cave-ins; acidizers, who pump acid down the well and into the producing formation to increase oil flow; perforator operators, who use subsurface “guns” to pierce holes in the casing to make openings for oil to flow into the well bore; sample-taker operators, who take samples of soil and rock formations from wells to help geologists determine the presence of oil; and well pullers, who remove pipes, pumps and other subsurface devices from wells for cleaning, repairing and salvaging. Many other skilled workers-such as welders, pipefitters, electricians and machinists - also are employed in maintenance operations to install and repair pumps, gauges, pipes and other equipment.

In addition to the types of workers required for onshore drilling, crews at offshore locations also need radio operators, cooks, ships’ officers, sailors and pilots. These workers make up the support personnel who work on or operate drilling platforms, crewboats, barges and helicopters.

Most workers involved in gas processing are operators. Gas treaters tend automatically controlled treating units that remove water and other impurities from natural gas. Gas-pumping-station operators tend compressors that raise the pressure of gas for transmission in pipelines. Both types of workers can be assisted by gas-compressor operators. Many employees in large natural gas processing plants-welders, electricians, instrument repairers and laborers, for example-perform maintenance activities. In contrast, many small plants are automated and are checked at periodic intervals by maintenance workers or operators, or monitored by instruments that alert operators if trouble develops. In nonautomated plants, workers usually combine the skills of both operators and maintenance workers.

Training and Advancement

Workers can enter the oil and gas extraction industry with a variety of educational backgrounds. The most common entry-level field jobs are as roustabouts or roughnecks, jobs that usually require little or no previous training or experience. Applicants for these routine laborer jobs must be physically fit and able to pass a physical examination. Companies also may administer aptitude tests and screen prospective employees for drug use.

Basic skills usually can be learned over a period of days through on-the-job training. However, previous work experience or formal training in petroleum technology that provides knowledge of oilfield operations and familiarity with computers and other automated equipment can be beneficial. In fact, given the increasing complexity of operations and the sophisticated nature of technology used today, employers now demand a higher level of skill and adaptability, including the ability to work with computers and other sophisticated equipment.

Other entry-level positions, such as engineering technician, usually require at least a two-year associate degree in engineering technology. Professional jobs, such as geologist, geophysicist or petroleum engineer, require at least a bachelor’s degree, but many companies prefer to hire candidates with a master’s degree, and may require a Ph.D. for those involved in petroleum research. For well operation and maintenance jobs, companies generally prefer applicants who live nearby, have mechanical ability and possess knowledge of oilfield processes. Because this work offers the advantage of a fixed locale, members of drilling crews or exploration parties who prefer not to travel may transfer to well operation and maintenance jobs. Training is acquired on the job.

Promotion opportunities for some jobs may be limited due to the general decline of the domestic petroleum industry. Advancement opportunities for oilfield workers remain best for those with skill and experience. For example, roustabouts may move up to become switchers, gaugers and pumpers. More experienced roughnecks may advance to derrick operator and, after several years, to driller. Drillers may advance to tool pusher. There should continue to be some opportunities for entry-level field crew workers to acquire the skills that qualify them for higher-level jobs within the industry.

Due to the critical nature of the work, offshore crews, even at the entry level, generally are more experienced than land crews. Many companies will not employ someone who has no knowledge of oilfield operations to work on an offshore rig, so workers who have gained experience as part of a land crew might advance to offshore operations.

As workers gain knowledge and experience, U.S. or foreign companies operating in other countries also may hire them. This can be a lucrative and exciting experience. Experience gained in many oil and gas extraction jobs also has application in other industries. For example, roustabouts can move to construction jobs, while machinery operators and repairers can transfer to other industries with similar machinery. Geologists and engineers may become involved with environmental activities, especially those related to this industry.

Earnings

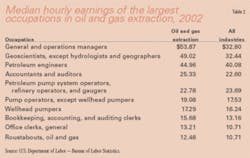

Average wage and salary earnings in the oil and gas exploration and production industry are significantly higher than the average for all industries. According to the U.S. Department of Labor, the average hourly earnings of non-supervisory workers in the oil and gas industry are $19.27, compared with $14.95 for all workers in private industry. Employees at offshore operations generally earn higher wages than do workers at onshore oil fields. College-educated workers and technical school graduates in professional and technical occupations usually earn the most. Earnings in selected occupations in oil and gas extraction appear in table 2.