Surfactant boosts polymer EOR effectiveness at Daqing

Field results and laboratory tests show that including surfactant treatments can lengthen the polymer injection effectiveness to 30 months from the 3 months previously experienced at the Daqing oil field.

Currently polymer flooding in the field produces more than 12 million tonnes/year of oil (240,000 bo/d); however, the process required overcoming injectivity problems in the polymer injection wells.

Daqing Oil Field Co. Ltd., a unit of PetroChina Co. Ltd., operates the field, which is in China’s northern Heilongjiang province

Polymer flooding

About 12% of polymer injection wells at Daqing had poor injectivity or decreasing injectivity. Poor injectivity decreases the benefits of polymer flooding and increases casing damage caused by high injection pressure.1

To solve this problem, Daqing started surfactant injection to decrease the injection pressure in 106 polymer injection wells. The surfactant increased the effective injectivity period to 30 months from the 3 months previously.

Daqing currently stimulates most of the polymer injection wells with surfactant.

Laboratory experiments

Laboratory experiments analyzed the benefits of injecting surfactant.

At Daqing, the polymer used is partially hydrolyzed polyacrylamide (HPAM) with a 25% degree of hydrolysis and 1.7 million g/mol molecular weight. Daqing Petroleum Chemical Co. manufactures the polymer.

Daqing Petroleum Institute manufactures the sodium carboxyl sulfonate surfactant with an active content of 51 wt %. The surfactant has an average 385 g/mol molecular weight.

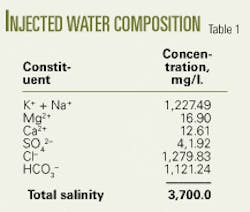

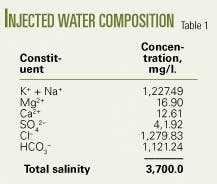

The laboratory experiment used inorganic salts added to distilled water to simulate the injected water in the pilot. Table 1 lists the water’s composition and salinity.

Harbin Chemical Co. manufactured the chlorine dioxide oxidant, which has a 5.0 wt % concentration.

The produced crude is paraffin-based with a 0.88 g/cc density and 9-10 MPa-sec viscosity at a 45° C. reservoir temperature.

The 4.9 cm by 10 cm sandstone artificial cores had 1-darcy permeability.

The experiments used a Baovi Corp. TX550A interfacial tensiometer to determine the interfacial tension between chemical solutions and synthetic oil at 45° C. The instrument reached equilibrium in about 60 min, at which time the interfacial tension values were measured.

The displacing apparatus allowed for the displacement of liquid in a porous media under high pressure and temperature (40.0 MPa and 120° C.).

A mineral oil, positive-displacement pump with an adjustable 0-0.1 cc/sec output provided a constant fluid-injection rate.

The experiment measured differential pressure during the floods through the core sample with a sensitive differential-pressure transducer (±0.17 MPa output under a 35.5 MPa maximum pressure).

Experimental procedure

At 45° C., a vacuum pump evacuated the cores to less than 5-mm Hg. The cores then were saturated with formation water (6,678 mg/l. salt) to determine pore volume before injection of the crude oil until water production stopped.

The next step, after waterflooding of the cores, involved injecting polymer solution until the injection pressure became steady. This pressure was recorded.

The next step injected of a 1.0 pore volume (PV) of chlorine dioxide and 1.0 PV of brine, followed by surfactant floods, as follows:

- 1.0 PV of 0.6 wt % surfactant with a 0.012 mN/m (milli Newton/m) surface tension and 100.0 PV of 1,500 mg/l. polymer containing 508.0 mg/l. NaCl.

- 1.0 PV of 0.6 wt % surfactant with a 0.013 mN/m surface tension and 100.0 PV of 2,000 mg/l. polymer containing 508.0 mg/l. NaCl.

- 1.0 PV of 1.0 wt % surfactant and 1.0 wt % alcohol with a 0.0042 mN/m surface tension and 100.0 PV of 2,000 mg/l. polymer containing 508 mg/l. NaCl.

The experiments had a 0.3 ml/min constant flow rate and collected the fluids from the cores in 10.0 ml increments, while injection pressure was recorded.

All parameters in the experiments were constant except for interfacial tension (IFT) or the polymer concentration. Table 2 summarizes the results obtained from the experiments.

The table clearly shows a lower IFT has a higher decrease in the injection pressure.

Previous studies indicate that the water relative permeability increased or the water injection pressure decreased with decreasing IFT.2-5 This suggests the correctness of the experimental results.

Table 2 shows that surfactant injection after 1.0 PV can decrease the polymer injection pressure by at least 48%.

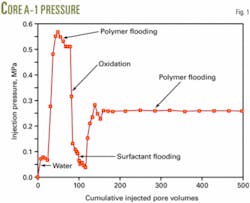

Fig. 1 is an example of the injection processes. This figure shows that polymer injection pressure after surfactant flood was steady after continuous injection of about 50.0 PV.

Field results

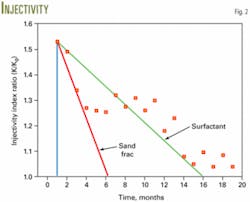

Fig. 2 compares the effect of surfactant in an injection well that has been fractured with quartz sand. K0 is the injectivity index before test and K is the injectivity index after test.

The effective period for fracture in Daqing is only 6 months, which is much shorter than for production wells.

By yearend 2004, the field had 106 polymer injection wells simulated with the surfactants (Table 3), decreasing the average injection pressure of each well by 0.9 MPa and increasing the injection rate by 18.6 cu m/day The longest effective injection reached 19 months with an average effective period of 15 months (Fig. 2).

Acknowledgment

The author thanks the Scientific Research Fund of Heilongjiang Provincial Education Department (No. 1054101) for the support of this project and Professor Wang Demin for his help.

References

- Wang, D., “Study of the four technologies that have influence on the sustainable development of Daqing oilfield,” Daqing Oil Geology and Development, Vol. 21, No. 1, 2002, pp. 10-19.

- Bardon, Charles, et al., “Influence of Very Low Interfacial Tensions on Relative Permeability,” SPE Journal, October 1990, pp. 391-401.

- Ronde, H., “Relative Permeability at Low Interfacial Tensions,” SPE Paper No. 24877, SPE ATCE, Washington, DC, Oct. 4-7, 1992.

- Ronde, H., “Effect of Low Interfacial Tensions on Relative Permeability in Some Gas Condensate Ssytems,” SPE Paper No. 25072, European Petroleum Conference, Cannes, France, Nov. 16-18, 1992.

- Harbert, L.W., “Low Interfacial Tension Relative Permeability,” SPE Paper No. 12171, SPE ATCE, San Francisco, Oct. 5-8, 1983.

The author

Fulin Yang ([email protected]) is a post-doctoral researcher in the University of Wyoming department of chemical and petroleum engineering. He previously worked as a research engineer for Daqing Oil Field Co. Ltd. His research interests include enhanced and improved oil recovery processes. Yang has a PhD in petroleum engineering from Daqing Petroleum Institute, China.