LEAN ENERGY MANAGEMENT-11: Martingale control of 4D reservoir performance provides constant watch on field profitability

Roger Anderson, Albert Boulanger - Columbia University, New York City

Wei He - CitiGroup, New York City;

Ulisses Mello, Liqing Xu - IBM, Yorktown Heights, NY

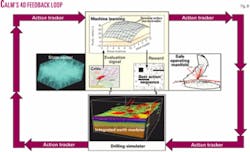

Computer-aided lean management (CALM) requires a feedback loop between actions taken in the field and the return of metrics that score the success or failure of those actions.

This feedback is fed into a model that continuously recomputes optimal solutions to keep the next actions “always-in-the-money.” Such a feedback control system that simultaneously optimizes both economic value and operational aspects of “e-fields” is called a “Martingale controller.”

Four-dimensional seismic monitoring of reservoir performance provides an excellent example of the power of such a CALM system that maximizes profitability even with extreme price fluctuations and geological uncertainties.

The tracking of fluid drainage over time (called 4D) is a modern development aimed at improving reservoir monitoring. 4D has introduced several powerful new observational tools into the development engineering arsenal, such as time-lapse seismic differencing, fiber-optic monitoring arrays in casing, and downhole sensors of many types.

This 4D application holds great promise as the keystone to a new, integrated reservoir management strategy that is able to image changes not only within a reservoir but also within the stack of reservoirs that make up most of the oil and gas fields of the world today.

Yet the industry is only just developing the controller logic for many components of 4D monitoring. For example, 4D seismic monitoring is still centered on reacquisition using 3D methodologies that are hard to exactly duplicate. Consequently, field operators concentrate on seismic reprocessing and reinterpretation, instead of the differencing of time-lapse data itself.

In addition, seismic modeling is 1D and 2D, and acoustic rather than 3D and elastic like the earth. To add to the simplification, analysis is built around one reservoir at a time, instead of the system of stacked reservoirs as an integrated whole.

A CALM controller for 4D seismic reservoir management, in contrast, is focused on the need to maximize profitability of the whole at all times and under all uncertainties. The CALM controller integrates the observed 4D seismic differences with a continuously running reservoir simulator to understand the production pathways of fluid withdrawal in each field.

What is missing from most e-field or “smart field” controllers is the computational operating framework (OF) that allows for the seamless and rapid feedback between and among the many and varied software applications and data streams that are required for modern reservoir management. We call the seismic/reservoir modeling integration of such CALM software “4D SeisRes,” or 4D Seismic Reservoir Management.

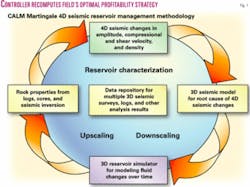

4D SeisRes requires a feedback loop that must consist of at least the following workflow combinations (Fig. 1):

- 4D analysis of time-lapse seismic changes for at least two, but as many as practical, 3D seismic volumes acquired at different times during the production history of a field, and their time-depth conversion, normalization, and differencing;

- Well log analysis looking for time-lapse changes in the same logs run over several different time intervals in wells and their depth-time conversion;

- Reservoir characterization of stacked reservoirs using geostatistical co-kriging;

- Exporting of all data, with time-stamps, into the same earth model;

- 3D fluid flow simulation, preferably using finite element modeling;

- 3D seismic modeling, preferably elastic rather than acoustic, to generate synthetic seismic cubes to match the 4D seismic observation time steps;

- Differencing of 4D model vs. 4D observed seismic data;

- Analysis of the difference-of-the-differences between the model and observed results;

- Optimization that identifies changes in physical properties of the reservoirs that are required to match fluid withdrawal, pressure changes, and seismic differences as closely as possible; and

- A continuous “feedback loop” to the beginning above so that the computation is dynamic (24/7 and never completed until the field is abandoned).

The architecture and design of the interaction of 3D seismic modeling with statistical reservoir characterization, the 4D observed seismic differences, a finite element reservoir simulator, and seismic inversion and migration codes are a sophisticated computational task not currently commonplace.

The task requires an extensible operating framework that enables the interpretation workflow to move easily among various vendor applications needed to complete the feedback loop described above, from geological, to geophysical interpretations, and on to the engineering implementations required of optimal performance by the modern electronic oil field asset team.

Operating framework

4D SeisRes design and implementation efforts are sizable and require the creation of Integrated Process Teams (another Lean stalwart).

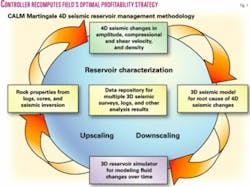

The architecture of the OF for the system that we implemented at Columbia and IBM Research for a Baker Hughes sponsored project contains the following major geological, geophysical, and engineering components (Fig. 2):

1. All actions within any of the many applications of the subsystems are recorded within the OF using a web-based action tracker we call the “Active Notebook.” Like a laboratory scientist’s lab book, it allows any previous experiment to be redone.

2. A vendor-neutral data model with a persistent input/output data repository (PIO) is required because the data sources for your favorite applications are not likely to be kept in the same data management systems. Rapid reviews of present and previous analyses can then be quickly and easily reviewed via versions stored in the PIO data repository.

3. Access to the many vendors’ applications must be provided using automated “wrappers” (Fig. 3). For example, we allow the user to choose between popular reservoir simulators from Schlumberger (Eclipse) and Halliburton (VIP) at the same time within our OF. The wrappers enclose the vendor applications and automatically manage the connectivity, data trafficking, and versioning of inputs and outputs.

4. We add an “event handling” mechanism to make applications run asynchronously (in parallel, but not necessarily at the same time). We parse the workflow among several applications simultaneously and distribute it to the client/server network, then reassemble it as completed. That way, we do not have to wait for one program to finish before beginning another.

5. There must also be a rich set of reusable, extensible “containers” to hold engineering, geological, and geophysical data so that new applications and data types can be added to the OF management system easily and quickly.

6. An automated meshing system is provided to create the framework needed by the reservoir simulator to build its model from any set of stacked horizons or other geological interpretations such as scanned maps and charts (Fig. 3). We use MultiMesh, an automatic meshing system from IBM that is “topological” so that whatever the grid requirements of an application are, its 3D connectivity can be quickly computed in finite difference, finite element, upscaled, or downscaled versions as needed (Fig. 4).

7. There must be a common data viewer, a web-based visualization system that crosses applications. The user can then communicate the visualization of progress of his computer simulations over the web as colleagues around the world manipulate the images in real time as they are recomputing (Fig. 5).

null

4D optimization laboratory

The key ingredient to our Martingale 4D controller is the optimizer.

In fact, it must be more like an “Optimization Laboratory” that contains a set of tools that can be deployed at any time and any place within the SeisRes OF to provide parameter optimization services.

It is implemented as a loosely coupled, component-based system because the need for parameter estimation varies from application to application and vendor to vendor.

The ”optimization work bench” allows a selection of options, including hybrids that combine algorithms of different types, to produce the most appropriate solutions. The technical goal is to quickly implement suboptimization loops to facilitate the optimization process for the 4D seismic reservoir simulation.

Consider an example that tracks the drainage of oil by two wells over 15 months (Fig. 5).

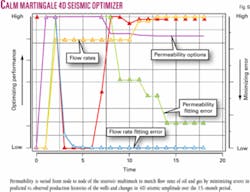

The optimizer consists of three components: optimization solvers, forward simulation wrappers, and simulation data converters, each of which must be developed separately for reservoir property characterization, reservoir simulation, petrophysical property characterization, and 3D seismic simulation. The optimizer converges on a single “best approximation” result that simultaneously solves for permeability variations and flow rate changes, with error estimators for each (Fig. 6).

null

Day-to-day use

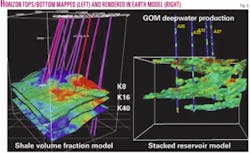

A modern, real-time reservoir management system must be able to characterize multiple, sequential 4D seismic surveys; seismic attribute volumes that vary with offset; many repeated well logs of different types and vintages; geostatistically-derived data volumes in both spatial and “stratigraphic” grids; 3D fluid saturation volumes and fluid-flow maps; fluid-interface monitors, multiple horizons and fault surfaces, and other data types that are only on the R&D drawing board now (Fig. 7).

Being able to view all these different types of data-spatially registered with respect to one another in the local real-world coordinate system and rendered in a variety of modes so that the interrelationships can be perceived-is a key to Martingale control of an e-field.

Only with such a sophisticated 4D controller can a global view of the system be achieved so that computer-aided lean management will deliver profitability that is “always-in-the-money.”

Project descriptions

All the supermajor oil companies have implemented their own unique versions of 4D CALM systems, complete with well-developed feedback loops.

Several presented implementations of integrated reservoir monitoring systems like the 4D SeisRes description above May 2 at the 2006 Offshore Technology Conference. The economic benefits are truly impressive.

Shell described results from the Gulf of Mexico, including Mars field. Chevron presented 4D optimization in Genesis field in the gulf. Total demonstrated the economic benefits from 4D monitoring of Girassol field off Angola. BP followed with 4D constraints to reservoir uncertainty in Valhall field of the North Sea.

Statoil showed the benefits of cross-disciplinary integration during 4D monitoring at Heidrun field, also in the North Sea, and Petrobras described impressive 4D reservoir monitoring results in the Campos basin.

Previously, at the Society of Exploration Geophysicists meeting, ExxonMobil had given an excellent 4D reservoir monitoring example from offshore Equatorial Guinea. In one of the West African examples, multiple seismic surveys were used for 4D analysis costing an additional $30 million or so that resulted in a new well that has produced $700 million in previously bypassed pay.

The evolution in CALM’s 4D methodology has been from:

- Verification of the scientific foundations of the seismic differencing schemes used, to

- Development of both amplitude and time-shift imaging to bring out the 4D changes over time, to

- Petrophysical and rock mechanical follow-up, to

- Continuous monitoring from sensors embedded into the sea floor and wellbores, and now to

- Real options management of well production through feedback of economic and reservoir conditions to an optimizer that varies the chokes and production profiles of producers and injectors simultaneously to truly manage for optimal production for the first time in industry history (Fig. 8).

No longer is CALM experimental, but it is moving into the standard operational methodologies for the world’s largest oil and gas fields, with a few notable exceptions. 4D CALM methodologies under many names and guises have been used in Indonesia, Malaysia, Canada, Yemen, and Abu Dhabi, in addition to the basins discussed above.

However, we are not aware of the use of the technology by any OPEC operator or by Mexico, Venezuela, or Russia.

This is actually good news for those worried that we will be able as an industry to meet future oil demand. It can be expected that CALM methodologies will enter these oil provinces as oil supply invariably tightens toward the middle of the century and recovery efficiency is required to increase in these areas of current abundance as well.

The authors

Roger Anderson (anderson@ ldeo.columbia.edu) is Doherty Senior Scholar at the Center for Computational Learning Systems at Columbia University. He has a joint appointment at the School of Engineering and Applied Sciences and the Lamont-Doherty Earth Observatory. A cofounder of Bell Geospace, an exploration company specializing in gravity gradiometry, he has a PhD from the Scripps Institution of Oceanography.

Albert Boulanger is senior scientist at the Center for Computational Learning Systems of Columbia University. Before that, he was at the Lamont-Doherty Earth Observatory. He was CTO of vPatch Technologies and a Research Developer at BBN. He specializes in complex systems integration and intelligent reasoning components that interact with humans in large scale systems. He developed the active notebook and other web technology contained in the Lamont 4D SeisRes software system.

Wei He is a computer scientist at CitiCorp in New York City. Before that, he was chief implementor of the Intalio patient tracking software at the University of Texas Medical Branch at Galveston. He was chief scientist of vPatch Inc. and head of optimization research for the 4D Technology Group at the Lamont-Doherty Earth Observatory of Columbia University before joining vPatch. He is a major contributor to the 4D SeisRes software system. He has a PhD from Columbia University.

Ulisses T. Mello is a research scientist at IBM Corp.’s T.J. Watson Research Center and adjunct associate research scientist at Columbia University’s Lamont-Doherty Earth Observatory. He is also the IBM Research Relationship Manager for the chemical and petroleum industry sector. He worked at the Petrobras research center in 1987-94. He has a PhD and MA in geology from Columbia University, MS in geology from Federal University of Ouro Preto, and BSc in geology from University of Sao Paulo.

LiQing Xu is a computer scientist in the petroleum research sector at IBM Corp.’s T.J. Watson Research Center in Yorktown Heights, NY. Before that, he worked at J.P. Morgan and the Lamont-Doherty Earth Observatory of Columbia University. He is the primary architect of the Lamont 4D SeisRes software system. He has an MS in computer science, MPhil in geophysics from Columbia University, and MSc and BSc from Petroleum University of China.