Rising UK natural gas imports call for more processing units

Steve R. Jackson

Adrian J. Finn

Terry R. Tomlinson

Costain Oil, Gas & Process Ltd., Manchester, UK

The UK’s dependence on imported natural gas and LNG will increase dramatically in the near future. The UK may need to import up to 40% of its natural gas by 2010 and up to 90% by 2020.

The UK’s self-sufficiency in natural gas has rapidly declined; for the first time the UK has become a net importer (see accompanying box, p. 59). Winter gas prices are now 10 times higher than 4 years ago, which is affecting such big industrial consumers as ammonia producers and power generators.

Many potential LNG imports will require further processing to reduce the Wobbe Index (WI) and meet UK National Transmission System (NTS) specifications. In addition, new domestic gas prospects are likely to be of lower quality and may require new processing schemes.

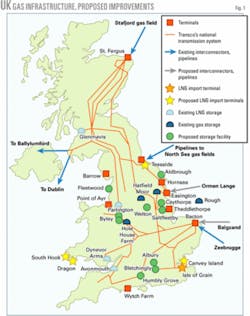

Currently, the main projected increase in imported gas is from Norway, mainly via the Langeled pipeline that will make landfall in northeast England (carrying gas from the giant Ormen-Lange development by 2007-08) and from Europe via the existing Zeebrugge-Bacton Interconnector and the Balgzand-Bacton pipeline (operational by 2007).

Fig. 1 shows the UK natural gas infrastructure.

The latter two lines will link the UK with the European gas grid and may open up potential supply sources from the former Soviet Union (FSU).

Several LNG import terminals projects are under construction or evaluation. The first is on the Isle of Grain near London, which commenced LNG imports in 2005. Two more LNG import terminals, Dragon and South Hook, are under construction at Milford Haven in Wales but will not be fully operational until around 2007.

A further potential development is the upgrade of the former LNG import terminal at Canvey Island, near London. Vaporized LNG from these terminals could supply around 25% of the UK’s overall gas demand by 2020.

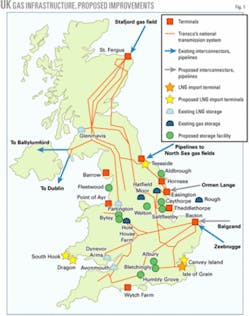

Imported natural gas and LNG will both have varying quality. A report in 2003 said that imported gas or LNG is likely to have a higher WI range than currently acceptable in the NTS.1 The allowable WI range for the UK is 47.20-51.41 million Joules/cu m. This narrow range may place the UK at a disadvantage, compared to other European countries, when it tries to procure LNG on the international market.

In addition to imported-gas quality issues, depletion of existing offshore UK gas fields and a drop in the number of new UK gas field developments have led to evaluation of more marginal (lower quality) gas fields that would need additional treatment and processing facilities to meet NTS specifications.

Selecting an optimum gas processing scheme requires consideration of several factors, including: feed specification and its variability; process integration options; local market for LPG; response to demand fluctuations; and overall process efficiency.

Recent UK gas trends

A new gas processing terminal constructed by Costain in Northwest England is designed to process 130 MMscfd of gas from the Irish Sea. This project was technically challenging due to the high acid-gas content and high mercaptan levels in the natural gas feed.

Trace sulfur compounds degrade many solvents used for acid-gas removal, and they usually become ineffective at meeting treated-gas organic sulfur specifications.

The H2S level in the treated gas had a specification of less than 1 ppm (vol); the total organic sulfur content was less than 8 ppm (vol). The treated gas is passed to existing gas-conditioning facilities that include a nitrogen-rejection unit (NRU).

Only a limited number of acid-gas removal technologies are feasible for this duty, and very few references exist worldwide for major gas processing applications handling high level of relatively heavy mercaptans. We conducted a thorough review of appropriate gas-sweetening technologies with solvent suppliers and assessed detailed property prediction procedures.

In the selected scheme, the sulfur-rich gas from solvent-regeneration feeds a sulfuric acid production plant. Although sulfuric acid has essentially negligible value in the UK, this approach was preferred to a Claus plant (that would produce sulfur) because of the high capital cost and the low return on investment due to the low value of sulfur.

New challenges

Gas producers are currently considering developing low-WI gas fields in the southern North Sea that have previously been uneconomic. These gas fields typically are high in CO2 and nitrogen.

Our recent study work has examined offshore applications of existing bulk CO2-removal technologies to treat gas prior to pipelining it to shore.2 The simpler process technologies, particularly membrane-based separation, tend to be better suited to large-scale offshore applications where space, weight, and reliability are important. All CO2-removal projects must consider CO2 disposal or “sequestration” because disposal to the atmosphere is unacceptable. When the removed CO2 can be economically transported, it may be feasible to use it for enhanced oil recovery (EOR).

Alternatively, the CO2 must be sequestered in a depleted reservoir or the seabed. The high oil-recovery levels historically achieved offshore UK and Norway mean that EOR is difficult to justify in the North Sea, although companies have evaluated this option based on the current high prices of crude oil (OGJ, May 17, 2004, p. 48; Aug. 8, 2005, p. 37).

Imported natural gas

The quality of imported gas varies according to its country of origin. Norwegian gas, imported via St. Fergus (or soon to be imported at Easington) typically has a WI range above the normal NTS specification; Dutch gas, imported via the Bacton Interconnector, would typically have a relatively low WI.

Gas blending to maintain NTS specification is the simplest option to cater to off-specification gas. At St. Fergus, for example, Norwegian gas imported via the Vesterled pipeline is rich but generally blended offshore.

Although the maximum WI is marginally outside NTS specification (maximum of about 52 million Joules/cu m), it will decrease gradually. By 2010, the gas supplied via the Vesterled pipeline should meet the NTS WI specification.

By contrast, Norwegian gas imported via the Langeled pipeline will also have a high WI, but gas blending is likely to become more problematic as the amount of gas imported from the Ormen-Lange field increases. Nitrogen ballasting to reduce WI may therefore be required at the Langeled import terminal at Easington.1

The only nitrogen-generation plant in the UK that has operated for rich-gas ballasting was built at Total AS’s St. Fergus gas terminal in the mid 1980s. To improve nitrogen recovery, the plant used a proprietary modification to Costain’s standard cryogenic nitrogen generator.

Imported LNG

Imported LNG creates quality and distribution challenges. As gas distribution changes from northern North Sea production to southern-based import terminals and pipelines, the gas-transmission system must be strengthened.

The two new LNG import terminals in Wales necessitate the building of new cross-country pipelines and compression stations to deliver the gas into the existing grid. In addition, as the UK becomes more dependant on imported gas, new gas-storage is being proposed and built onshore in depleted gas fields and salt caverns to increase the strategic reserve of gas supplies for harsh winters.

The natural-gas liquefaction process removes such hydrocarbons as pentanes and heavier to prevent freeze-up in the downstream cryogenic sections. Lighter hydrocarbons such as ethane, propane, and butane are liquefied along with methane. These hydrocarbons contribute to the higher calorific value and, therefore, the higher WI.

During LNG transportation there is also a tendency for the WI to increase when lighter components boil off, which makes the LNG heavier over time and over longer transportation distances. Import LNG specifications, therefore, vary greatly from country to country.

Most potential LNG supplies have a WI of 51-54 million Joules/cu m (above UK limits). Because of this, new LNG terminals will generally require further processing of rich gas or will need to blend it with nitrogen or lean gas to reduce its WI.

Regasified LNG can be blended with NTS gas to meet its WI specification, but this can restrict its transportation capacity on a thermal basis. Blending with air is a cheaper option but is currently unviable in the UK because the gas would easily exceed the oxygen specification of 10 ppm (vol) set by the gas transporter, National Grid (formerly Transco).

Table 1 shows the NTS specifications.

Another possibility is the extraction of heavy hydrocarbons from the regasified LNG, although this reduces gas volumetric flow. Without a local market for the extracted LPG, this product has no economic value.

Stripping out NGLs at the LNG export terminal would also lower the WI of the produced LNG, but the economics of this option are only favorable for large LNG train capacities. For example, QatarGas II uses an NGL-removal system for its two 7.8-million-tonne/year trains destined for the South Hook import terminal at Milford Haven.

Nitrogen ballasting is generally the preferred method for natural-gas derichment. The gaseous nitrogen can be absorbed in the export LNG stream in a recondenser vessel before the LNG sendout pumps and vaporizers (Fig. 2).

Gaseous nitrogen can also be compressed to high pressure and then injected into the export-gas header although injection at low pressure into the recondenser has the advantage of lower compression power.

Currently, nitrogen-ballasting facilities have been installed at the Grain terminal. Selecting the optimum scheme for WI reduction at other locations depends on a number of factors including: feed specification and its variability, local market for LPG, response to demand fluctuations, and overall process efficiency and availability.

Because LNG quality varies considerably from country to country, the design basis for a nitrogen-ballasting plant would vary depending on where the supplier obtains LNG. With the developing LNG spot market, greater flexibility in the nitrogen-generation plant and nitrogen-supply configuration will likely be required at import terminals.

Our experience is that the most effective design of a nitrogen-ballasting plant will generally be multitrain units with the capacity for gas or liquids production. This approach allows the plant a high degree of flexibility when it responds to changing operating scenarios and the need to cover a range of terminal sendout rates and unloading scenarios.

The capacity range for nitrogen-ballasting plants is typically 100-500 tonnes/day.

Nitrogen rejection

The designer of an NRU plant must consider the most cost-effective overall facility including feed compression, pretreatment, nitrogen removal, and product-gas compression. There are many processes for nitrogen removal from natural gas.

An integrated approach to overall facility design is required because the lowest-cost NRU does not necessarily lead to the most cost-effective overall facility when feed and product compression are taken into account.

The pretreatment facilities required for NRUs are essentially similar to those required for conventional gas processing and include removal of CO2, sulfur, water, and hydrocarbon dew-point control. Deeper removal may be required to avoid freezing at the cryogenic temperatures in the NRU.

Removal of heavy hydrocarbons (aromatics in particular) is the conventional practice for low-temperature gas plants and many systems have been installed that use lean oil absorption, adsorption, and partial condensation.

For gas flow rates of less than 50 MMscfd, the designer should consider pressure swing adsorption (PSA) and semi-permeable membranes. For large flow rates for which there is a need to separate nitrogen and methane to an appropriate purity and high methane recovery, however, PSA requires relatively high power consumption and capital cost.

The only process technology that is economic for large flow rates is cryogenic distillation. The power consumption in a cryogenic unit is not excessive compared to that required just to deliver gas to the pipeline system.

Cryogenic nitrogen rejection

Process selection and optimization for cryogenic nitrogen rejection requires balancing the cryogenic process efficiency, flowsheet complexity, and cost against the cost of compression. The machinery configuration must be carefully addressed to minimize power consumption.

The key parameter for process cycle selection is nitrogen content. Feed pressure, flow rate, and contaminant levels are also important; but the nitrogen content essentially dictates the cryogenic cycle.

Because of the large impact of product compression on the total plant cost, the cryogenic cycle must be very efficient. For NRUs, these issues are well understood, which usually makes the choice of process cycle relatively straightforward.

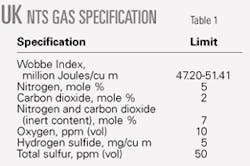

The feed flow rate and feed-gas nitrogen content influence the capital cost and power consumption of a nitrogen-rejection process. It is normal to bypass some feed gas around the cryogenic process to reduce cost. This means that the nitrogen level in the NRU product hydrocarbon stream must be lower than the overall sales-gas specification so that the blended export gas is on specification.

The rejected nitrogen stream usually contains a small amount of hydrocarbon (predominantly methane). Environmental and economic criteria dictate the hydrocarbon content in the nitrogen vent stream; this is typically set at about 0.5 mole %. The economic optimum methane level in the vent stream derives from a relatively straightforward evaluation of revenue loss against capital and operating costs.

Depending on local environmental regulations, this stream may be vented, reinjected, or incinerated.

Fig. 3 shows a typical removal unit.

For a feed-gas nitrogen content of 7-20%, an upstream column would be used to increase the nitrogen level to the downstream fractionation system. This may consist of an integrated double fractionation column process or, in more modern plants, a single fractionation column.

As experience in nitrogen-rejection plant design grows, plant designs are becoming simpler and less power-intensive and nitrogen rejection is becoming more widespread.

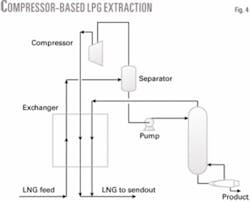

LPG extraction

Where the infrastructure exists to transport and use LPG products and an LNG import terminal anticipates rich LNG, WI reduction with extraction of LPG from LNG at the import terminal may be economically attractive (Fig. 4). LPG extraction is of particular interest where local refineries could process and utilize the propane, butane, and natural gasoline fractions.

Many processes are available for LPG extraction. Schemes typically include warming and partial vaporization of the LNG sendout stream at low pressure followed by distillation of the liquid fraction. The low-pressure vapor stream is then compressed and condensed against the LNG feed stream before pumping to the sendout pressure.

This type of scheme typically needs significant mechanical and heat energy for compression and reboiler heat duty, respectively. The requirement for vapor compression also limits flexibility when the plant responds to throughput changes.

To address this problem, a major energy company and Costain have cooperated on development of a process scheme for LPG recovery that offers greater simplicity and flexibility than existing schemes. This scheme allows high recovery of LPG from the LNG export scheme without the need for compression of the column overheads stream.

All of the energy input required for separation is used as heating or pumping power, which allows a high degree of integration with other process systems.

Acknowledgments

The authors thank Costain Oil Gas & Process Ltd. for its support. ✦

References

1. Ilex Energy Consulting, “Importing gas into the UK-Gas Quality Issues,” Report to DTI Ofgem & HSE, November 2003.

2. Shaw, T.P., and Hughes, P.W., “Optimize CO2 Removal,” Hydrocarbon Processing, May 2001.

Historical development of the UK gas industry

In the 1960s, the first natural gas produced from the southern North Sea required relatively little processing because it had a high methane content. Simple glycol-based dehydration processes, with mechanical or Joule-Thomson refrigeration, were sufficient for the gas to meet NTS specifications.

Large-scale production of gas from the northern North Sea began in the 1970s via terminals at St. Fergus in northern Scotland, via the Far North Liquids and Associated Gas System (FLAGS) pipeline system, and later the Scotish Area Gas Evacuation (SAGE) pipeline. This gas required extraction of NGLs and removal of CO2 and H2S. Cryogenic ethane extraction was used to supply NGL feedstock to the Royal Dutch Shell PLC-ExxonMobil Corp. Fife ethylene plant at Mossmorran.

In 1992, Costain Oil, Gas & Process Ltd. completed a third NGL-fractionation train at Mossmorran to increase total plant capacity to 15,000 tonnes/day (tpd) of propane, butanes, condensate, and ethane. Recent major gas supplies, notably from the Norwegian Statfjord field and the Heimdal gas field via the Vesterled pipeline, have ensured the long-term viability of the St. Fergus gas plants and the Fife ethylene plant.

The 1970s also saw the strategic building of several peak-shaving LNG storage facilities to provide security of supply during extreme winter demand by liquefying natural gas for up to about 270 days/year. Plant capacity is typically 400 tpd in two trains.

The expander-based liquefaction facility built by Costain at the Isle of Grain was converted to a 3.3-million-tonne/year LNG import terminal.

In the 1980s, development of Irish Sea gas fields experienced several challenges including the presence of H2S, but more significantly a high nitrogen content. Initially, nitrogen-rich gas was blended with gas of higher calorific value and passed to the NTS, but this became increasingly difficult. Eventually, deployment of large-scale cryogenic nitrogen-removal facilities became essential.

North Morecambe gas, produced from the Irish Sea and processed by Hydrocarbon Resources Ltd. at Barrow, contains approximately 8-mole% nitrogen. For this site, Costain developed and patented in the late 1980s an integrated cryogenic nitrogen-rejection process that uses a prefractionation column upstream of a heat-pumped fractionation column.

Further activity in the Irish Sea included the Liverpool Bay development, which feeds gas to the Point of Ayr terminal, northern Wales, to remove acid gases. Some exported gas is used at the adjacent 1,400-Mw Connah’s Quay power station, operated by PowerGen (now E.On).

To allow flexibility of power-plant operation, Costain designed and built a nitrogen-rejection unit to process 200 MMscfd of gas of 8-11 mole % nitrogen (OGJ, Feb. 1, 1999, p. 36). An integrated three-column process provided flexibility. A high-reliability sales gas compression system was installed, based on the use of electric drives for cost and environmental reasons.

In the early 1990s, Costain designed and built the 800-MMscfd Teesside gas processing plant for Enron Corp. (now operated by px Ltd.) in northeast England (OGJ, Jan. 3, 2000, p. 37). Development at Teesside represented the fourth area to receive gas after southeast England, northern Scotland, and northwest England.

North Sea gas is supplied via the 2-bcfd Central Area Transmission System (CATS) pipeline system and has a relatively high liquids content.

Train 1 can producing about 900 tpd of NGL using only Joule-Thomson expansion and passes the bulk of the dew-pointed gas to the 1,875-Mw Teesside power plant, the world’s largest integrated combined cycle gas-fired power plant.

Train 2 was designed as a more sophisticated turboexpander plant to recover more NGL (more than 1,000 tpd), while exporting high-pressure sales gas to the NTS. Uniquely in the UK, the flexibility of the Train 2 plant allows plant operation to respond to market demand for liquid fuels, thereby maximizing revenues.

The authors

Steve Jackson ([email protected]) is a senior process engineer with Costain Oil, Gas & Process Ltd., Manchester, UK. He has spent 5 years with Costain, mainly working on gas processing studies and projects including NGL extraction and fractionation, LNG boil-off gas recovery, LPG extraction from LNG, nitrogen rejection, gas treating, and dehydration. He holds a masters degree in chemical engineering with management from the University of Birmingham, UK. He is a Member of the IChemE and a chartered engineer in the UK.

Adrian J. Finn is technology development manager with Costain Oil, Gas & Process Ltd., Manchester, UK, with responsibility for front-end work including supervision of proposals, process studies, and basic engineering projects as well as process technology development and patents. Finn has spent 23 years with Costain, mainly on cryogenic gas processing projects. He holds a BScTech in chemical engineering and fuel technology from Sheffield University and an MS from Leeds University (both UK). Finn is a fellow of IChemE and is a chartered engineer in the UK.

Terry Tomlinson is general manager front-end solutions with Costain Oil, Gas & Process Ltd., Manchester, UK, with responsibility for all front-end activities. He has spent 32 years with Costain involved in gas plant projects across a wide variety of applications including gas storage, reception, and distribution, as well as cryogenic nitrogen rejection and NGL recovery. Tomlinson holds a BSc in chemical engineering from Leeds University, UK. He is a fellow of IChemE and is a chartered engineer in the UK.