New expandable-profile liners used in Iran, China, Tatarstan

Gabdrashit S. Abdrakhmanov

Nigamatyan Kh. Khamityanov

Nail N. Vildanov

TatNIPIneft, Tatar State Research &

Design Institute, Tatneft JSC

Bugulma, Russia

Tatneft has developed guidelines for running expandable-profile liners in wells with complex geology, based on operations in Iran, China, and Tatarstan.

Since the early 1980s, expandable casing strings developed by Tatneft engineers have been extensively used for isolation of trouble zones.1-8

Different expandable systems, known as expandable-profile liners, have been developed and tested and have continued to improve. Tatneft has addressed a number of issues with expandable-profile liners: the applicability and enhanced reliability of liners subjected to high pressure differentials and high temperatures; the increasing length of expandable-profile liners for isolation of lengthy trouble zones in incompetent rocks (e.g., sloughing shales); and a reduction in the time required for system installation.

Currently, an expandable-profile liner system referred to as OLKS-216 (Russian acronym designating equipment for local well casing with 215.9 mm diameter) is most commonly used for isolating trouble zones without cementing and without wellbore diameter loss. The system withstands pressure differential up to 20 MPa and temperature up to 150° C.

Tatneft’s expandable systems

The uniqueness of the Tatneft’s expandable systems lies in the specific design of expandable pipes. The pipes have a two-channel (or multibeam) profile along the entire length while the ends are cylindrical, with the diameter the same as the diameter of the circumscribed circle of the profiled portion. Cylindrical ends are provided with threads to connect pipes with each other and with the drillstring, which runs the expandable-profile liner downhole.6

The method of expanding the string differs radically from other methods known in the industry and consists of the following two stages:

1. Simultaneous expansion of the profiled portion of the string (95-97%) through 12-14 MPa hydraulic pressure, which is created by injection of drilling mud inside the string.

The major benefits of the system are the application of profiled pipes and simultaneous expansion of the string in the downhole conditions by drilling-mud pressure. These are necessary prerequisites for reliable placement of the expandable-profile liner in the project interval of the wellbore, and any displacement of the profile liner in either the axial or radial direction, once the profile liner has been set in place and expanded by hydraulic pressure, is next to impossible.

2. Mechanical expansion of the cylindrical threaded ends (3-5%) once the expandable-profiled string has been straightened and tightly pressed to the formation face, through either radial expansion with roller and cutter expanders or top-down pulling of special mandrels or expansion cones.

The above features ensure 100% passability of drilling tools once the expandable-profiled string has been set in place.

Troublesome geology and complex in-situ conditions, as well as inappropriate mechanical expansion tools, may bring about certain wellbore problems. Fighting those emerging challenges would require additional time and money. Such situations are not infrequent in sloughing shales.

Trouble zone isolation

Our experience of lost circulation isolation in incompetent rocks-Well No 41-KL in the Iranian Kupal oil field-may serve a good example to warn operators against possible missteps.

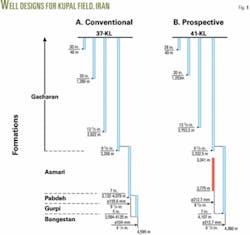

Fig. 1a shows typical well designs in the Kupal field. After installation of casing in the abnormally high-pressure Gacharan formation with 95⁄8-in. string, the underlying Asmari formation is typically drilled with a 83⁄8-in. bit (212.7 mm) with 81.5 psf (1.02 tonne/cu m) drilling mud and isolated with 7-in. (177.8 mm) liner.

A 61⁄8-in. (155.6 mm) bit is used through the Pabdeh and Gurpi formations. The Pabdeh formation is drilled with 81.5 psf (1.3 tonne/cu m) mud. But the operator has to raise the mud weight to 97-104 psf (1.56-1.67 tonne/cu m) in the Gurpi formation and add lost circulation material (LCM). A 5-in. diameter liner is typically run through these two formations.

The final target is the Bangestan reservoir, drilled with a 41⁄8-in. (104.8 mm) bit with 82.5 psf (1.32 tonne/cu m) mud and completed open hole.

Drilling with a 41⁄8-in. bit presents a lot of problems during drilling and production phases, and also affects future well intervention operations. But the task set before the expandable-profile liner technology group- to substitute a 41⁄8-in. (104.8 mm) bit for a 61⁄8-in. (155.6 mm) bit- was successfully accomplished.

An expandable-profile liner 434.5 m long was set in Well No 41-KL (Fig. 1b). However, the services provider, JSC “Tatneft,” spent twice as much time as planned as a result of unexpected complications attributed to the complex geological environment. The exposed rocks were generally shales and drilling was accompanied by sloughing, cavern washouts, and, in some cases, tight holes. To allow for all these contingencies the services provider and the operator had to revise the project several times.

Job execution, Iran

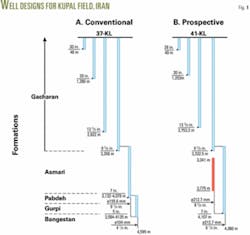

Fig. 2 presents the original plan and the actual project results. According to the project design suggested by Tatneft, the Asmari formation had to be isolated with two expandable-profile liners: A 120.5 m-long section had to be set in the expected gas show zone, and the 331-m long section, connected with the first expandable-profile liner, needed to be run to the bottom of the Asmari formation.

The original project guidelines called for installing the 1.5-m long box-type pup joint with 232-mm ID in the lower portion of the 95⁄8-in. casing string, to which the upper section of the first expandable-profile liner had to be connected.

In the process of drilling with the 95⁄8-in. string, however, the operator faced troubles that would have made it difficult to run the string freely and set the thin-wall box-type pup joint. The operator decided to run the 95⁄8-in. string without the pup joint and without connecting the expandable-profile liner to the string. Caverns that would be formed in the process of drilling with an 83⁄8-in. (212.7-mm) bit had to be cemented.

The original project guidelines also provided for drilling with an 83⁄8-in. (212.7-mm) bit with simultaneous reaming of the wellbore, which had to be attained through the use of near-bit-expandable underreamer. In this case, the expansion job would have been excluded, and the operator would have had enough time to set an expandable-profile liner before the shales started to slough.

But since the operator had no experience of drilling with simultaneous underreaming in Asmari, it declined to try this approach. Instead, the operator decided first to drill the interval with an 83⁄8-in. (212.7-mm) bit and then ream it with the expandable underreamer.

Once the Asmari formation had been penetrated, the well was logged. The log analysis interpretation indicated the gas show zone had not been recorded. Therefore, the team revised the project once again and ran the expandable underreamer through the entire exposed interval. The 434.5-m long expandable-profile liner was set in one trip.

All these deviations from Tatneft’s original project led to significant loss of time and to future problems.

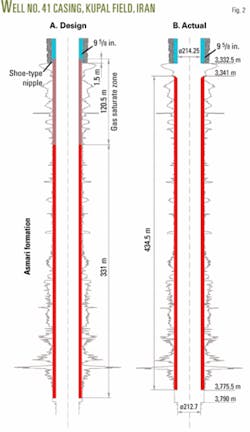

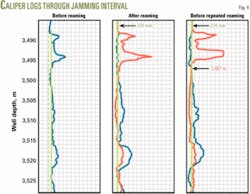

Figs. 3 and 4 present caliper logs before and after reaming; after cementing below the 95⁄8-in. string shoe; after drilling out of cement plug; and before repeated reaming of tight-hole sections.

Caliper logs showed that delay in operations had damaged the wellbore: Caverns enlarged in diameter and tight spots appeared in the already reamed wellbore interval. This was additional evidence that time is pivotal when dealing with sloughing rocks.

After repeated reaming of the tight sections, setting the profile liner in place, and inflating it with mud pressure, it was expanded with a 211-mm rigid mandrel. Still, borehole restriction and squeezing of the profile liner continued.

The assembly for repeated expansion of the profile liner included the same 211-mm rigid mandrel, this time used as a centralizer, as well as a 216-mm expandable cone. At 3,497 m depth, the rigid mandrel stuck. The rig pulled out the collapsible 216-mm cone and the stuck mandrel was recovered by reciprocation and rotation of the drillstring under different loads (up to 200 tons). Once the mandrels were pulled out of the hole, the inner diameter of the profile liner was sized with the 213.5-mm single-roller expander.

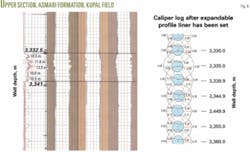

Fig. 5 presents a caliper log of the interval where the mandrel was sticking, after the expandable-profile liner had been installed. One can see how the profile liner was indented into caverns, which happened while releasing the stuck tool. Because of the good bond between the profile liner and the wellbore walls, however, created by expansion with hydraulic pressure, the profile liner was able to withstand the loads associated with reciprocating and rotating the drillstring.

Cement was falling out of caverns below the 95⁄8-in. string shoe, complicating the attempted release of the stuck tool. This is evident from the caverns’ sizes (Fig. 3) and caverns’ sizes above the profile liner (Fig. 6). The pulled out tools were also blocked with cement.

Notwithstanding all the unexpected complications, the expandable-profile liner was successfully set in the 3,341-3,775.5-m interval (Fig. 2b). The Pabdeh and Gurpi formations were drilled with an 83⁄8-in. (212.7-mm) bit, flushed with weighted drilling mud according to the project guidelines, and cased off with 7-in. (178-mm) liner. The well was drilled to the projected depth with a 61⁄8-in. (155.6 mm) bit without further problems (Fig. 1b).

Drilling in China

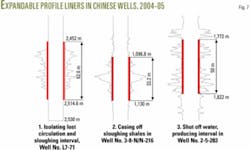

Tatneft performed similar jobs in three more wells in China in the TuHa field, Xinjiang Uyger Autonomous Region, northwest China, and in the Shengli field, near Bohai Bay, eastern China.

In Well No. L7-71 in the TuHa field, operated by TuHa Petroleum Exploration and Development Corp., Tatneft installed an expandable-profile liner, 62.6-m long, in the 2,452-2,414.6 m interval.

Two other jobs were performed for Shengli Yellow River Cementing Co. in the Shengli field:

• In Well No. 3-8-N/N-216, the trouble interval (1,452-1,486 m) was isolated with an expandable-profile liner.

• In Well No. 2-5-238, the expandable-profile liner shut off the water-producing zone in the 1,772-1,822 m interval.

Single-cutter and roller expanders were used for mechanical reaming and sizing of the expandable-profile liner in all the wells described above.

Technology improvement

A new task set before the team of Tatneft scientists and engineers was to reduce the time spent on casing trouble zones. The solution was to set expandable systems in a single trip. Such expandable systems have been developed and are currently being tested in oil wells in the Republic of Tatarstan. To date, one-trip expandable-profile liners have been set in three wells.

In the first operation, all operations including wellbore reaming, well logging, running of 49-m long section of expandable-profile liner in the preset interval and expanding it with pressure, were completed in 27 hr. In two subsequent wells, the operations took 40 hr, and the lengths of expandable-profile liner sections were 67 m and 66 m.

Lessons learned, recommendations

JSC Tatneft has gained invaluable experience installing expandable systems in complex geologic settings. The foregoing examples show that:

1. Cementing washouts before setting an expandable-profile liner is not a viable option. Eventually causes additional problems. If the project guidelines provide for trouble interval isolation immediately below the 95⁄8-in. string shoe, running a box-type pup joint and an extension of the casing string from bottom is a must.4 6 For such special applications, thick-walled, custom-made pup joints are available with strengths compatible with that of the 95⁄8-in. string.

2. During isolation of trouble zones in sloughing shales, drilling while simultaneously reaming the wellbore with an expandable underreamer is the best solution. This eliminates the need for additional reaming operations, thus reducing the openhole exposure time, which is the most critical factor in drilling incompetent rocks.

3. Rigid mandrels are not fit for mechanical reaming and sizing of the ID of the expandable-profile liner. For this purpose, expandable cones or roller-cutter expanders should be used.

4. Thief zones in incompetent rocks, such as sloughing shales, should be isolated with expandable systems set in place per one trip, immediately after exposing of the trouble interval.✦

References

1. Abdrakmanov, G.S., Zainullin, A.G., Ibatullin, R.Kh., Bikchurin, T.N., Gabidullin, R.S., “Experience on Application of A219/216 Profile Liner in Almetyevsk Drilling Department,” RNTS Bureniye No 11, VNIIOENG, 1981, pp. 8-9.

2. Abdrakmanov, G.S, et al., “Method of Construction of Multiple-String Wells,” US Patent No. 4876322 (filed: Dec. 11, 1990), China Patent No. 14939 (filed: May 26, 1989), Canada Patent No. 1301635 (filed: May 26, 1992), Mexico Patent No. 171802 (filed: Jan. 23, 1989), European Patent Authority Patent No. 353309 (Germany, Great Britain, France, Italy; filed: Nov. 22, 1989).

3. Ibragimov, N.G., Kaveev, Kh.Z., Abdrakhmanov, G.S., et al.: “Expandable liners isolate sloughing zones in directional, horizontal wells,” OGJ, Jan. 6, 2003, p. 42.

4. Takhautdinov, Sh.F., Ibragimov, N.G., Abdrakmanov, G.S., et al., “Liners extend casing length without wellbore diameter loss,” OGJ, Aug. 12, 2002, p. 41.

5. Takhautdinov, Sh.F., Ibragimov, N.G., Abdrakmanov, G.S., et al., “Expandable liners isolate water influx from directional, horizontal wells,” OGJ, Aug. 19, 2002, p. 53.

6. Abdrakmanov G.S., “Well casing with expandable pipes,” teaching aid for students, Samara: ROSING Publishing House, 2003.

7. Takhautdinov, Sh.F., Ibragimov, N.G., Abdrakmanov, G.S., et al., “Expandable liners protect permeable zones in Russian oil wells,” OGJ, Jan. 6, 2000, p. 39.

8. Abdrakmanov, G.S., Ibatullin, R.Kh., Robinson, B., Powell, B., “Isolation profile liner helps stabilize problem wellbores,” OGJ, Sept. 11, 1995, p. 50.

The authors

Gabdrashit S. Abdrakhmanov (e-mail: [email protected]) is a chief drilling expert at Tatneft JSC. He is a professor and member of the Russian Academy of Natural Sciences. Abdrakhmanov graduated from the Moscow Petrochemical and Gas Institute and holds a PhD in technical science.

Nigamatyan K. Khamityanov (e-mail: [email protected]) is deputy head of the drilling department at the Tatar Oil Research and Design Institute (TatNIPIneft), Bugulma, Russia. He graduated from the Ufa Petroleum Institute, Ufa, Bashkortostan, with a PhD in technical science and has more than 10 years of experience in local well casing using expandable-profile liners.

Nail N. Vildanov (e-mail: [email protected]) is a senior research officer in the drilling department at Tatar Oil Research and Design Institute (TatNIPIneft), Bugulma, Russia. His responsibilities include design and introduction of technological processes for local well casing using profile liners. Vildanov holds an MS in oil and gas well drilling from the Ufa Petroleum Institute, Ufa, Bashkortostan. He previously worked in a Tatneft drilling department in charge of drilling oil wells.