STANDARDS ACTIVITY-Conclusion: Ormen Lange HTHP lessons prompt design, standard adjustments

The high temperatures and high pressures associated with the 30-in. multiphase lines of the Ormen Lange project off Norway crossing very uneven seabed forced a reevaluation of standards addressing allowable pipeline free-span lengths.

This second of two articles focuses on particular design parameters for free-spanning high temperature-high pressure pipelines such as the Ormen Lange multiphase lines and illuminates a case study of Ormen Lange that can be applied to other HTHP pipelines.

The first article examined the shortfalls of existing standards as applied to Ormen Lange, as well as the testing and analysis that ultimately not only helped determine the route of the Ormen Lange export pipeline but also led to an update of DNV free-span standards.

Design approach

Equation 1 shows one of the most important parameters related to free-span design; the fundamental or natural frequency of the span.

High temperatures and high pressures (HTHP) can affect the allowable free-span lengths and fatigue caused by the effective axial force in the natural frequencies. The free-span design of most of the flowlines and the hot end of export pipelines must account for this state.

Equation 2 shows the governing equation of motion for an infinitesimal element of pipe, while Equation 1 provides the classical solution of this accounting for the correct boundary conditions.

Removing the inertia term and including external and internal pressures yields Equation 3.

Solving this equation, assuming a pinned-pinned boundary condition, gives Equation 4, the critical buckling load, or the Euler load.

Equation 4 shows that there is a clear relationship between how the internal and external pressures affect both global buckling and the natural frequencies of a span. A safe and reliable free-span design requires that the potential buckling of the pipeline and the release of axial force be accurately predicted.

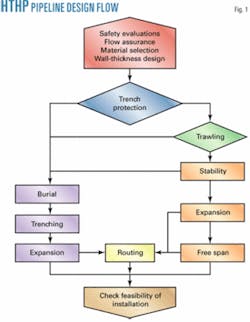

Fig. 1 illustrates a typical design flow for HTHP pipelines. Deciding whether to bury the pipeline or install it on the seabed follows initial design (pipe diameter, WT, material selection, and insulation).

Requirements for impact resistance and coating weight may be established by studying potential seabed interference from trawl gear and on-bottom stability issues. If these design aspects are not solved properly, the pipeline must be buried.

Checking the integrity of the pipeline also requires that any potential buckling be addressed. Since the free-span design may strongly depend on the correct effective axial force as an input, any end expansion and global buckling must be addressed before free-span design. These steps are consistent with the recommendations of DNV-RP-F105 and also the essence of findings addressing the problem of lateral buckling and free-span design of flowlines.1 2

After the buckling-expansion and free-span design aspects have been solved, the feasibility of installing the pipeline with the selected method and equipment must be verified.

Fig. 2 shows an example of a pipeline installed on uneven seabed. Internal pressure and temperature will cause the pipeline to lift off the seabed at high points and buckle sideways. Buckling response is caused by and strongly influences the effective axial force and thereby the free-span lengths and their fatigue lives.

In addition to the effects of global buckling and release of effective axial force, span deflection will gradually increase as the effective axial force increases. This deflection will release some of the axial force and may also cause the span to vanish as the span height is limited, and the pipe makes contact with the seabed in the middle of the span.

For these reasons, span response expressions based on linear beam theory cannot be applied and must be replaced by, for example, nonlinear FE analysis.

Ormen Lange’s 30-in. multiphase export lines to shore are installed on very uneven seabed and include numerous vertical and horizontal curves. These curves act as initial imperfections and cause the pipelines to buckle laterally at several locations.

The design uses this buckling by accounting for the decrease in compressive effective axial force caused by temperature and internal pressure, thereby increasing the acceptable free-span lengths and minimizing span intervention costs. Three-dimensional, nonlinear FE analysis provides a basis for the buckling and free-span design.

Case study

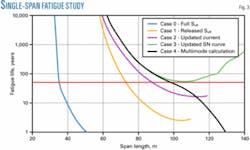

A case study of one of the 30-in. export lines demonstrates the effects of some of the free-span activities performed at Ormen Lange. The case refers to a water depth of nearly 900-m close to the templates and includes (Fig. 3):

• 0 (base case), no release of effective axial force due to buckling.

• 1, release of effective axial force due to buckling.

• 2, updated long-term distribution of current after extended measurement campaign.

• 3, updated SN curve due to fatigue testing.

• 4, updated multimode response calculation.

The study assumed that the span is a single, isolated span (no multispanning section), and that the response quantities such as natural frequencies and mode shapes could be roughly estimated from the beam theory-based expressions in DNV-RP-F105. This approximation can be used easily to demonstrate the effect of the improvements made in the Ormen Lange project.

Fig. 3 shows the fatigue lives for each case as functions of span length. The maximum acceptable span length increases significantly from around 35 m to 72 m when accounting for the release of effective axial force due to lateral buckling.

The improvements in fatigue life due to updated long-term distribution of current and an improved SN curve bring the fatigue curve up to a level (Fig. 3, Case 3), at which the minimum fatigue life becomes higher than the design life (50 years) for all span lengths.

The increase in fatigue life with spans exceeding 100 m seems incorrect but is due to the counteracting effects of decreasing frequencies (not beneficial) and stress cycles (beneficial) with span length. In the left part of the fatigue curve, the frequency effect is most important, while in the right part the effect of the stress cycles becomes the dominating factor.

Case 3 shows that there is no limitation in span length due to fatigue, but the effect of higher modes due to the Ormen Lange-specific guideline has also been calculated. Fig. 3, Case 4 shows a maximum acceptable span of about 100 m for this specific case, clearly demonstrating the importance of addressing the multimode (i.e., higher modes) response.

Challenges

Pushing the limit for pipeline free-span design but still maintaining a sufficient safety level requires understanding in both physical and probabilistic terms the phenomena involved. Pipeline design typically approaches the problem with presumably conservative assumptions and models.

Multispan scenarios in the North Sea, Persian Gulf, Southeast Asia, West Africa, and Gulf of Mexico have been designed with DNV RP F-105 coupled with a conservative approach for adding damage from several potential modes or simply not allowing for cross-flow (CF) vortex-induced vibrations (VIV).

The industry, however, uses free-span design criteria mainly based upon experimental results under two-dimensional conditions with heuristic analysis models. Long spans, and in particular multimodal response for multispan scenarios with limited experience, require better three-dimensional understanding of the in-line (IL)-CF interaction.

Long free pipeline spans are somewhat similar to steel catenary risers exposed to low-mode VIV. Standard industry design practice uses semiempirical models for CF and ignores IL and combined IL-CF VIV. This approach is paradoxical, since the in-line component normally dominates the design for pipeline free spans.

Present pipeline design is based on a response model for vibration amplitude as a function of hydrodynamic, geotechnical, and pipeline parameters. This is adequate when remaining inside the scope of experience and experimental tests reflected by present codes and guidelines.

For long spans in macroroughness areas, several unresolved issues remain before seabed response models can be fully qualified. These issues include the effect of the current boundary layer close to the sea floor, nonhomogenous flow along the span or adjacent multiple spans, large-scale turbulence, and combined wave and current flow.

These issues call for more advanced computation. Navier-Stoke solvers continuously improve, but codes that can reproduce the experimental results with sufficient reliability are not available.

Compared to isolated spans, which quantify mode shapes and frequencies based on the free-span length, soil stiffness, bending stiffness, effective axial force, and effect from sagging, multispan scenarios are very case specific. This specificity calls for more intricate guidelines to address the possibility of many modes being excited by high current velocities.

Results

The Ormen Lange VIV tests represent a step towards increased knowledge of multispan scenarios and helped facilitate project-specific guidelines.

Lateral buckling and associated release of effective axial force need addressing before free-span design, especially for HTHP pipelines.

Multimode response is important and must be considered in the design phase for long single spans as well as multispanning sections.

An updated project-specific design guideline, based on VIV model tests, provides advanced computational methods to assess long single spans undergoing single-mode and multimode response.

Routing becomes very important in reducing the number and length of spans. High-resolution survey data provide a basis for such routing activities.

Improving the data basis, knowledge, and design methodology for long free spans can create substantial savings in seabed preparation and avoided span intervention.

DNV has revised DNV-RP-F105 to reflect the findings and recommendations of the Ormen Lange project. ✦

References

1. “Recommended Practice: Free-spanning Pipelines,” DNV-RP-F105, March 2002.

2. Galgoul, N.S., De Barros, J.C.P., and Ferreira, R.P., “The Interaction of Free-Span and Lateral Buckling Problems,” International Pipeline Conference, Calgary, Oct. 4-8, 2004.