Canadian refiner uses improvement program to increase refining profits

In 2002, Petro-Canada issued a challenge to its refining and supply organization to add $150 million (Can.) of profits, and do it in 9 months with little or no capital. They referred to this task the Q1 Project.

Petro-Canada accomplished this goal by adopting "pacesetter" work practices with the help of the pacesetter performance process (PPP) that Solomon Associates Inc. developed.

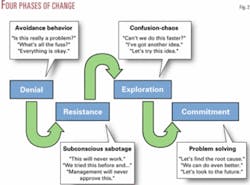

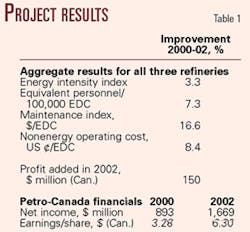

Petro-Canada was able to add $150 million (Can.) of profits from the three refineries included in the project. The company decreased energy use, lowered maintenance and operating costs, and reduced staffing (Table 1).

Background

Petro-Canada operates three fuels refineries and one lube refinery in Canada with a combined nominal crude capacity of 313,200 b/cd. Petro-Canada has products sales of about 56.8 million cu m/day representing 17% of the Canadian market. Each refinery occupies a distinct position in the marketplace:

Montreal. This refinery imports crude from Western Canada and international sources.

Oakville. Located just outside Toronto, the refinery is the smallest and least sophisticated of the three fuels refineries.

Edmonton. This refinery processes synthetic crude produced from Canadian tar sands.

Mississauga. This lube oil facility is just outside Toronto. The Mississauga plant is one of the few lube oil facilities producing food-grade oils.

The lube refinery was not a full participant in the Q1 Project. In addition, Petro-Canada has announced its intent to close the Oakville refinery (OGJ, Sept. 15, 2003, p. 9). The Q1 Project would provide management a clear picture of the full potential of each refinery, which was considered in the decision to shut down the Oakville refinery.

Pacesetter process

The PPP started more than a year before the challenge was issued. The target was based in part on the results of the first two phases of the PPP (see Pacesetter performance box).

During 2001, Solomon completed Phases 1 and 2 and developed a detailed performance-gap analysis by benchmarking performance against specialized peer groups. Benchmarking with a single peer group is seldom a deep enough analysis to tell the entire story. A perfect example was the analysis done to establish staffing targets for the Montreal refinery (see Montreal box) where staffing targets were built from the ground up by a multidimensional benchmarking exercise.

At the end of Phases 1 and 2, Petro-Canada had a clear understanding of the potential of each refinery and an outline of an implementation plan. While the strengths and weaknesses varied for each refinery, three major initiatives formed the core of the implementation plan:

- Operator-driven reliability. This was used to involve operating personnel in maintenance activities and get maintenance and operations to work together as a team.

- Operator effectiveness. Petro-Canada was not fully using the refinery supervisor, which diminished the role of process engineers.

- Planning and optimization (P&O). Petro-Canada had focused on supplying refined products to the retail marketing division at the lowest possible cost instead of trying to maximize overall profits. This philosophy was so ingrained that the refinery planning linear program (LP) models were set to minimize cost as an objective function. The P&O initiative focused on creating a maximum profit mindset.

Petro-Canada adopted the best-practice team (BPT) approach. The Montreal and Edmonton refineries took the lead in operator effectiveness and operator-driven reliability, respectively. Pilot programs for operator effectiveness and operator-driven reliability were developed and tested; national BPTs were formed to transfer this knowledge to other refineries.

A national team with representatives from all four refineries and head office developed and led the P&O effort. The teams were designed to implement the recommendations from Phases 1 and 2.

The challenge

By February 2001, Petro-Canada was ready to implement the changes. A meeting of the top 30-40 managers in the refining and supply organization helped to develop buy-in to the process.

The meeting established a sense of urgency for the project and had a huge positive effect.

Subsequently, the employees did not question the value of the program; rather, they began to question whether it was achievable. They questioned the timeline.

Management provided resources and priorities to the BPTs so that it could focus on the Q1 Project. Solomon ensured that the BPTs did not waste time "reinventing the wheel" and that the process focused on creating sustained improvements.

The project

The Q1 Project involved more than 50 initiatives and everyone in the refining and supply organization. A major initiative was the max profit mindset initiative created by the P&O BPT.

This article focuses on the max profit mindset program, although the other initiatives in the Q1 Project were equally as important.

As previously mentioned, Petro-Canada had focused on supplying products to marketing at a minimum cost and did not focus on maximizing corporate profits. The first step in changing this mindset was a best-practice audit of the P&O process.

The best-practice audit accomplished two primary objectives—to provide Petro-Canada a complete understanding of best practices and to provide a third-party assessment of how their current practices "stacked up" relative to the best practices of other companies in the industry.

The best-practice audit identified two primary weaknesses in Petro-Canada's P&O department:

- The refinery LP models were not accepted as accurate. The LP model must be "universally recognized" as accurate. The P&O team should not be consuming problem solving time discussing whether the LP model is accurate.

The planning process was not discovering new profit opportunities. The planning process is not an exercise to balance volumes between feedstock supply, refineries, and marketing. The planning process should focus on finding new profit opportunities.

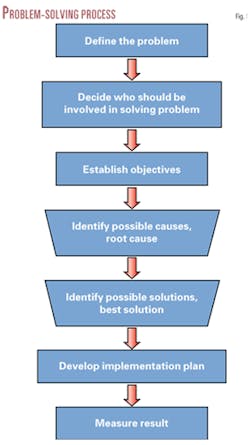

The audit also found many good processes and practices. One of the more significant findings was the high level of talent and cooperation already resident in the Petro-Canada organization. The recommendations and initiatives identified in the PPP were matched to the skills and capabilities of Petro-Canada employees. More than 60 people were trained in a seven step, problem-solving process (Fig. 1) to accelerate the project.

Petro-Canada's goal was to implement changes in 9 months. The P&O team divided all ideas into those that could be accomplished in 9 months and those good ideas that would have to wait. There was no time for major studies. The short timeline created a need for action.

The P&O team also looked at the task in terms of people, process, and hardware. Because there was no time for large capital projects, these ideas were moved to the "wait until later" stack. But the planning tools used and the planning process yielded enough ideas to meet the $150 million (Can.) goal.

LP model

The efforts to make the LP models at each refinery "universally accepted" involved several initiatives:

- Each LP model was reconfigured to maximize profit as the objective function. All parts of the organization had to be convinced that this approach provided a better way to run the business.

- Petro-Canada began comparing operating plans to actual results to identify areas where the LP models required improvement. If the plan-to-actual comparison resulted in a variance in gasoline or diesel production of more than 3 vol % or a variance in gasoline plus diesel production of 2 vol %, then a more rigorous examination of the variances occured.

- Process unit simulators for FCCs and hydrocrackers were used to create LP vectors for scenarios where the refinery had little or no operating data. The process simulators were tuned to match the Petro-Canada process units.

- Process unit engineers were given the responsibility for maintaining the LP model yield and operating cost data for their process units. Technical management established standards for cost and mass balances analysis performed.

- More than 40 people were trained in simple LP model techniques, economic analysis, and marginal economic theories.

Profit discovery

Two major issues were keeping the process already in place from being a true discovery process—the mindset of minimizing cost vs. maximizing profit and the existence of a few "sacred cows" that the process was reluctant to address. These issues were addressed with these initiatives:

- Responsibility for the planning process was clearly defined with the creation of two coordinator positions. The coordinators, although they did not create the plans, were responsible for the plans being acceptable. The coordinators also served as a clearinghouse for information, which put them in the best position to recognize opportunities or to see problems developing. Pacesetters do this effectively and often beat the competition to profit opportunities.

- The organization learned to talk in terms of dollars and cents. They started to express opportunities and problems in profit terms.

- After the seven step, problem-solving method (Fig. 1), several working sessions were held with feedstock supply, refining, and marketing people to brainstorm the best way to implement the max profit mindset.

- A more open environment was created at planning meetings, which was helped by having a Solomon representative present. After several meetings, the planning teams learned that management encouraged the new, more-open thinking and Solomon's presence was no longer needed.

- A process was begun to identify the three most significant bottlenecks in each process unit in each refinery. This results in more creative and profitable operating plans.

Critical success factors

Petro-Canada identified several factors that led to the project's success:

- Senior management support. Any effort of this magnitude must have the active and continuous support of senior management.

- Follow a proven process. Although many different approaches exist to improve performance, it is vital that a company choose a process that has been proven successful for its situation.

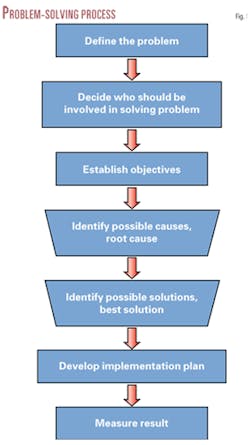

- Benchmark. Benchmarking current performance is effective in moving people beyond denial. Individuals and organizations tend to move through four phases of change: denial, resistance, exploration, and commitment (Fig. 2).

In the beginning of a project, employees will deny that change is needed. Benchmarking against valid industry data identifies performance gaps and also proves that a similar refinery has achieved superior performance.

Benchmarking can eliminate the need to talk to or visit better performers. This accelerates the change process.

- Apply best practices. Work practices create the results shown in the benchmarking analysis. Practices and behavior should change if a company is going to improve benchmarking results.

- Set clear objectives and priorities. Petro-Canada's management removed all the hurdles for the Q1 Project. When it prepared a strategic plan, the organization agreed to live with a pro-forma update to the previous year's effort instead of a new ground-up plan.

When Petro-Canada created a system to track the value of the initiatives, it applied the 80/20 rule. It realized that it was important to develop a reasonable estimate of the initiatives and not to create a document that would stand up against an independent audit.

- Set clear expectations. Expectations are different from objectives. Expectations go directly to the day-to-day behavior of employees. Petro-Canada clearly let every employee know that change was expected and that it was safe to behave differently.

- Create a sense of urgency. Everyone is busy; nobody has enough time. But pacesetters find time to do the important things. They go about their business with a sense of urgency.

- Collaborate. Few problems in today's business world are solved by one person and seldom by one department—collaboration is necessary. Collaboration is not just making an effort to hear all sides of an issue, but making the effort to understand all sides of the issue.

- Transfer learning. Every organization has strengths. It is likely that significant performance improvements can result if the bottom performers were elevated to the level of the average performer.

- Use an outside force. Change is difficult; it often only happens when an outside force intervenes. An outside force can focus 100% on making positive changes and improving performance.

Project results

Table 1 summarizes the results of the Q1 Project.

Before the Q1 Project, Petro-Canada typically focused on inventory levels, the need to balance octane production with marketing demands, and whether the LP model was correct. After the Q1 Project, the company focuses on topics like the sales margin of high-octane components into the US refining markets, whether the refinery should run a new type of crude oil, and a long list of "what if" LP model cases.

Acknowledgments

Petro-Canada acknowledges the special contribution of Nathalie Aubrey, Doug Kingdon, Normand Lariviere, Caroline Montplaisir, Paul Po, Paul Sacco, and Christine Yorke in making this project a success.

The authors

Joe Bruno ([email protected]) is a senior advisor in the refining and supply support group for Petro-Canada, Oakville, Ont., Canada. He has more than 27 years of work and management experience in various refining and supply areas including refinery operations, planning and process engineering, supply operations, planning and LP modeling, and product distribution. Bruno holds a BASc in chemical engineering from the University of Toronto and is a registered professional engineer in Ontario.

Michael J. Hileman (Michael.Hileman@Solomon Online.com) is a vice-president with Solomon Associates, a division of HSB Solomon LLC, Hartford, Conn. Before joining Solomon, Hileman was vice-president of supply, distribution, and sales for a large independent refiner-marketer. He holds a BS in chemical engineering from Rose-Hulman Institute of Technology, Terre Haute, Ind.