Mobile extraction process provides effective site remediation

A mobile version of the dual-phase extraction (DPE) process for remediating sites affected by petroleum product releases has been used effectively in emergency response and where the cost of a fixed DPE system was not justified.

DPE technology removes free product from groundwater and reduces dissolved-phase contaminant concentrations in groundwater.

The mobile version, Mobile Dual Phase Extraction (MDPE), has been used to remove gasoline, aviation fuel, kerosine, and diesel. Due to the emission of hydrocarbon-impacted off-gas during these events, emission-control equipment, such as a thermal oxidizer, is normally used to ensure compliance with air emission standards.

Although maximum vacuum extraction depth of a liquid column is limited to 1 atm, or about 34 ft below ground level, the simultaneous recovery of vapor with the liquid phase reduces the hydrostatic head of the column and increases the recovery depth significantly. DPE technology has been used to recover fluids from depths up to 80 ft below ground level.

Storage project

In December 2002, Explorer Pipeline Co. discovered a gasoline release at its Glenpool, Okla., storage terminal near Tulsa. Initial site investigation confirmed the subsurface soil and groundwater near the point of release were affected by petroleum products.

In January 2003, geoprobe holes confirmed and delineated the gasoline plume. Free product was recorded in 21 test holes with a thickness ranging from sheen to 2 in.

In a response to remediate the affected site, Explorer Pipeline solicited proposals from various environmental consulting firms to remove separated phase product and reduce hydrocarbon contaminants in the soil and groundwater to the Oklahoma Corporation Commission's risk-based cleanup levels and achieve final closure of the case.

Some proposals recommended traditional technologies to clean up this site. These technologies included pump and treat, air sparge-vapor extraction, and passive extraction using sorbent socks in the well bores. Due to the shallow depth of groundwater and low permeable lithology, Cinnabar Environmental Services, Tulsa, recommended MDPE technology to remove the free product and achieve the required cleanup levels at this site.

Traditional pump and treat would not be cost effective in remediating this site because it possibly could recover large volumes of groundwater that would require pretreatment and disposal. Also, air sparge and vapor extraction would be limited in removing free product and reducing hydrocarbon contaminants in the subsurface. MDPE, with its high vacuum pressure and high flow rate recovery, would be more effective in removing liquid product, impacted groundwater, and hydrocarbon vapor.

The high vacuum pressure generated by MDPE—20-25 in. Hg, compared to 8-9 in. Hg for the traditional vapor extraction blowers—lifts liquid and vapor simultaneously and overcomes the capillary forces in the vadose to release hydrocarbons adsorbed to soil.

When not removed, these entrapped hydrocarbons present a continued source of contamination to groundwater through infiltration and rising groundwater. High vacuum pressure applied to the smear zone also lowers the vapor pressure of hydrocarbons that will subsequently allow hydrocarbon molecules to volatize.

Remedial plan

In October 2003, nine soil borings-groundwater monitoring wells were installed in an area within the suspected hydrocarbon plume. The wells, designated MW-1 through MW-9, were drilled to about 9 ft below ground surface (bgs) with the exception of MW-6, which was drilled to a depth of 14 ft bgs. During the well installations, groundwater was encountered at 2.0-7.5 ft bgs. Free product was detected in one monitoring well. All monitoring wells were completed with 5 ft of 2-in. slotted screen.

MW-1 through MW-5 and MW-9 were used for recovery of free product, while MW-6, MW-7, and MW-8 were used to assess and monitor plume migration toward a nearby creek. Subsurface soil in the impacted area was characterized as dense clay with rock fragments from surface to about 4-6 ft bgs, and clay, silty clay, and weathered sandstone to total depth.

Soil borings were completed using hollow stem augers and 5-ft continuous sampling tubes. A representative sample from each foot of core was placed in plastic bags for headspace screening.

A photo ionization detector (PID) was used to screen soil samples for hydrocarbon vapor. One soil sample with the highest PID reading from each boring was submitted to a state-certified laboratory for analyses of benzene, toluene, ethylbenzene, xylenes (BTEX), and total petroleum hydrocarbon gasoline range organics (TPH-GRO).

null

Soil laboratory analyses indicated the subsurface soil had been affected by petroleum hydrocarbons. The highest benzene concentration in soil samples was 2.04 mg/kg in MW-1, and 1.68 mg/kg in MW-5. The corresponding TPH-GRO concentrations in these borings were 332 mg/kg and 229 mg/kg, respectively.

In October 2003, the monitoring wells were gauged, developed, and sampled for laboratory analyses of BTEX and TPH-GRO concentrations. Approximately 0.25 in. of free product was recorded in MW-5. Depth to groundwater during the sampling event ranged from 3.29 ft to 8.43 ft bgs. All monitoring wells were surveyed for casing elevations. Well survey data and water elevation suggested that groundwater flow was to the north-northeast toward the creek.

Groundwater laboratory analysis indicated that the groundwater was affected by petroleum hydrocarbons. The highest benzene concentration was recorded in Monitoring Well MW-1 as 9.270 mg/l. The corresponding TPH-GRO concentration in MW-1 was 71.2 mg/l.

MDPE application

Following groundwater sampling, MDPE was performed at the site in November 2003. Four MDPE events were performed in November 2003 through May 2004. After each MDPE event, groundwater was sampled to evaluate hydrocarbon reduction in groundwater. Following the May 2004 MDPE event, sampling data suggested that hydrocarbon concentrations in groundwater in MW-1 had decreased while hydrocarbon concentrations in MW-2, MW-3, and MW-4 had increased slightly.

Small increases in concentrations at some monitoring points are not unusual due to the dynamics of the extraction process and the possibility of hydrocarbons being released from the vadose zone. It is important to remember that the success of the process is based on the "net" effect that MDPE has on the groundwater system being treated.

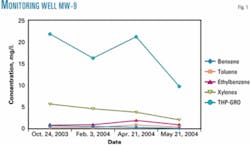

Concentrations in groundwater in the remaining wells—especially at the eastern perimeter of the plume—had decreased or remained stable. Fig. 1 shows the contaminants reduction in MW-9. Based on the calculated hydrocarbons removed by the DPE process, we suspected that a great portion of the hydrocarbons removed might have come from the vadose where they were not detected during the initial investigation.

High vacuum, dual-phase extraction

Envac Environmental Services LLC (Envac), Tulsa, performed the MDPE events at the Explorer Pipeline facility. Envac used a self contained, truck-mounted unit that consisted of a high- vacuum-pressure liquid ring pump, a water-storage tank, and a thermal oxidizer (Figs. 2 and 3).

Before each extraction event, the monitoring wells were gauged for depth-to-groundwater as well as free-product thickness. The first extraction event was performed on all monitoring wells, while the remaining extraction events were performed on MW-2, MW-3, MW-4, and MW-5, all within the bulk of the affected plume.

During the extraction, multiple wells were manifolded to the pump unit at one time for several hours, followed by the remaining wells. At the end of each extraction event a sample of the recovered water was collected and submitted for laboratory analyses of BTEX and TPH-GRO.

null

During the November 2003 extraction event, depth-to-groundwater in monitoring wells ranged from 5.7 ft below top of casing in MW-2 to 9.51 ft. Free product thicknesses of 0.02 ft and 0.01 ft were recorded in MW-1 and MW-2, respectively. Extraction was accomplished with stingers at about 1-2 ft below groundwater level.

Vapor removal ranged from 64 cfm to 110 cfm throughout this event with hydrocarbon concentrations ranging from 800 ppm to 2,900 ppm. Vacuum in the liquid ring pump's inlet stream was maintained at about 22 in. Hg (11.0 psi). A dilution relief valve at the liquid ring pump was also used to control vacuum pressures.

Bleed valves were used to enhance the extraction of free product and affected water at the wellheads. In addition to the vapor removal, about 1,260 gal of impacted groundwater were also removed during this remedial event.

During the December 2003 extraction event, average depth-to-groundwater was about 2.16 ft bgs. A thickness of 0.01 ft of free product was recorded in MW-1. Vapor removal ranged from 72 cfm to 132 cfm at a vacuum pressure of 21-24 in. Hg (10.3-11.8 psi) with hydrocarbon concentrations of 580-9,300 ppm. A total of 1,416 gal of liquid was extracted from monitoring wells during this event.

During the March 2004 extraction event, average depth-to-groundwater in monitoring wells was about 2.69 ft bgs. A thickness of 0.01 ft of free product was recorded in MW-1. Vapor extraction ranged from 72 cfm to 138 cfm at a vacuum pressure of 21-23 in. Hg (10.3-11.3 psi) with hydrocarbon concentrations of 300-6,000 ppm. A total of 1,469 gal of liquid was recovered during this event.

The fourth event was a 12-hr vacuum event that was performed in May 2004. Average depth to groundwater in monitoring wells was 5.32 ft bgs. No free product was recorded in any of the monitoring wells. Vapor extraction ranged from 72 cfm to 138 cfm at a vacuum pressure of 22-24 in. Hg (10.8-11.8 psi) with hydrocarbon concentrations of 590-5,300 ppm. A total of 1,780 gal of liquid was recovered during this event.

During the multiphase extraction events, hydrocarbons were removed as vapor and liquid phase. Vapor recovery rates and total hydrocarbon concentrations were used to estimate the volumes of equivalent hydrocarbons (gasoline) removed as vapor. About 14 gal of equivalent gasoline were recovered as vapor.

Using the laboratory analysis of the recovered groundwater samples and the volumes of recovered water, it was estimated that 97 gal of equivalent gasoline were recovered as liquid. A total of 111 gal was removed by the high vacuum extraction events as vapor and liquid.

Although the gasoline release at the Explorer Pipeline facility was not a major release, MDPE was successful in extracting, under high vacuum pressures, hydrocarbons at the water interface as well as the unsaturated zone. Hydrocarbon contaminants in ground water were reduced to risk-based levels that allowed the Oklahoma Corporation Commission to close this case.

The authors

James F. Sieck is corporate director of health, safety, security, and environmental for Explorer Pipeline Co., Tulsa. Sieck has spent more than 25 years in the petroleum industry, including 10 years in exploration and production and 15 years on product pipelines. During that time he has held a number of engineering, operations, and management positions. Sieck holds a BS in petroleum engineering from the University of Wyoming and an MS in environmental engineering from Oklahoma State University. He is a registered professional engineer in Oklahoma and Texas and a certified hazardous materials manager.

A.J. Andary is an engineering manager for Cinnabar Environmental Services, Edmond, Okla. He has 15 years' experience in environmental engineering and management. His environmental engineering experience includes air pollution control, wastewater treatment, hazardous waste management, underground storage tank site investigation, remedial system design, planning, coordination, installation, and operation and maintenance of treatment facilities. Andary holds a degree in chemical engineering from the University of Oklahoma, and he is a registered professional environmental engineer in Oklahoma.