Gas processors in Western Siberia target higher production in plans through 2010

The Russian gas industry occupies a major operational sector of the country's fuel and energy industry as well as the national economy.

In 2003, Russian gas production amounted to 600 billion cu m (bcm). The country's energy strategy through 2010, as approved by the government (Decree No. 1234-p; Aug. 28, 2003), envisions moderate increases in gas production up to 635-730 bcm. Russia's annual gas production will reach 770 bcm in 2020. The optimistic case envisions a growth to 750 bcm by 2010 and 900 bcm by 2020.

Nearly 80% of the explored gas reserves are in West Siberia, in Russia's major gas production region, the Yamalo-Nenetsk Autonomous District. Efficient management and use of the available hydrocarbon feedstock requires upgrading the existing gas processing plants and building new ones.

Gazprom's facilities

The following gas processing facilities operate within the framework of Gazprom:

- Astrakhan region, the Astrakhansky gas processing plant. For the last 10 years, gas production in the Astrakhan region has increased fivefold, reaching 11 bcm in 2003. The purpose of the Astrakhansky gas plant is to prepare and process natural gas and gas condensate. Total output is 12 bcm/year in natural gas and 3.0 million tonnes/year (tpy) in stabilized and processed condensate.

Orenburg region, the Orenburgsky gas processing plant and a helium factory. Maximum gas production in the Orenburg region was 47 bcm/year in mid 1980s; within the last 15 years, production has steadily decreased, reaching 21 bcm in 2003.

A unique gas processing complex has been built in the region whose production capacity is utilized at barely half its capacity at present because of the drop in gas production. The Orenburgsky gas plant includes three processing units, each of which processes natural gas and gas condensate. The inlet capacity is 45 bcm/year in gas processing and 12 million tpy in condensate.

- Western Siberia. The gas processing branch is represented by the Urengoy plant that prepares condensate for transportation by rail or pipeline in the city of Novy Urengoy and the Surgutsky plant for stabilized condensate.

Hydrocarbon condensate is transported from the Urengoy plant to Surgutsky plant by the existing condensate pipeline Urengoi-Surgut (698 km, 720 mm ID). Inlet capacity at Surgutsky is 8 million tpy.

Associated gas production

Russian gas processing plants are slowly but surely being upgraded and revamped with more modern processes and technologies. A significant amount of overcapacity in Russia in 1990s delayed expansions and improvements for these plants. In the next 5 years, the plants will complete construction projects started in the 1990s and begin new projects.

In Russia, as a whole, resources of associated gas in 2003 amounted to 50.1 bcm, including 38.1 bcm (76%) in western Siberia. Increases in domestic demand are slowly catching up to the potential supply from Russian gas plants. Utilization in 2003 was about 77-78%, up from 71% in 2000.

Until now, 8-11 bcm/year of associated natural gas (Table 1) together with NGL obtained during oil production have been flared and continue to be flared by oil companies.

This raw material is not supplied to gas processing plants of western Siberia for different reasons:

- Remoteness of small deposits from gas zones.

- Lack of collection, transportation, and processing systems in oil companies.

- Lack of gas pipelines from oil companies to Sibur, owner of the gas processing plants of western Siberia. Sibur is JSC Sibirsko-Uralskaya Neftegazohimicheskaya Companiya, a vertically integrated holding company that processes large volumes of hydrocarbons in Russia and produces more than 100 petrochemical products.

The basic feedstock for Sibur's products is associated natural gas, a strategically vital feedstock for the national petrochemical industry. Its use is not only an economical but also an ecological issue in the effort to reduce the adverse effects of the oil and gas industry on the environment. In the last few years, Sibur has undertaken to solve these problems in western Siberia. Difficult negotiations between Sibur and Gazprom, on the one side, and oil companies on the other are ongoing.

As a result, the producers of gas and light hydrocarbon feedstock are cutting flaring. The problems with western Siberian oil companies are well known in which these most valuable of gas products are making more pollution in the region.

The main products of the gas processing plants include dry stripped gas and liquid hydrocarbons C3+, known in Russian as "ShFLU," a mixture of propane, butane, pentane, and hexane produced at the gas processing plants. (ShFLU is a Russian language acronym for these components, a wide fraction of light hydrocarbons.)

In 2003, a total of 19.2 bcm of stripped gas, 3.3.million tonnes of ShFLU (including 1.67 million tonnes from JSC Sibur-Tyumen), 1.2 million tonnes of LPG, and 634,000 tonnes of naphtha (Table 2) were produced in Russia.

Industry structure in western Siberia

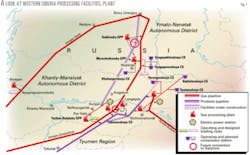

The western Siberia associated-gas processing industry currently includes eight plants with total capacity of 25 bcm/year (Fig. 1). All plants are subsidiaries of integrated companies:

- Lukoil owns and operates the Lokosovsky gas processing plant, 2.14 bcm capacity.

- Surgutneftegaz owns and operates the Surgutsky gas processing plant, 4.28 bcm capacity.

- Sibur owns and operates six plants, discussed in the following section.

In western Siberia, Sibur controls most facilities for associated-gas transportation and processing.

The production complex of JSC Sibur-Tyumen, an affiliate company of Sibur, consists of:

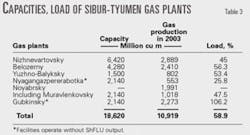

- Six gas plants with total capacity of 18.6 bcm.

- Six compressor stations: Tyumenskaya, Bakhilovskaya, Varieganskaya, Vyngapurovskaya, Vyngayakhinskaya, and Kholmogorskaya, total capacity of 9.6 bcm.

- A system of pipelines providing gas and gas products transportation.

The length of gas transportation network is 1,470 km; the products pipeline from the Belozerny gas plant to the Tobolsky petrochemical plant is 692 km. At present, only 7.1 bcm (65%) out of 11 bcm of associated gas delivered to all eight plants are involved in processing designed to extract the components of ShFLU.

Review of ShFLU potential feedstock base reveals that it suffers from, in many instances, the unavailability of safe transportation in gas and gas products pipelines. Large losses result by both ShFLU producers in western Siberia and consumers in the Urals and Volga regions are known to Sibur and other petrochemical manufacturers in Russia.

These companies could have accepted and transferred up to 5 million tpy by 2005 and up to 7 million tpy through 2010. The volume of ShFLU produced and transported by Sibur at present is roughly equal to the ShFLU produced by Gazprom. Gazprom forecasts increased production of liquid hydrocarbons of up to 26 million tpy during 2010-15 and, therefore, the output of ShFLU will increase to 5 million tpy.

ShFLU processing, transportation, a 5-year outlook

The production facilities just discussed were commissioned in the 1970s and 1980s, with the design operational periods of the main equipment being 25-30 years. The plants were designed according to state-of-the-art techniques for that time, which provided for 93-95% extraction of targeted components from the associated gas. Although the equipment remains in a satisfactory condition in most cases, some parts of the facilities have become outmoded. Gas processing and the transportation complex have not changed radically in the past 2 years, but there are some positive trends.

Implementation of the program to renovate and modernize gas processing and transportation will continue during 2005-10.

The 500-700 mm ID products pipeline from the Gubkinsky gas plant to the Tobolsk petrochemical plant, which produces monomers, has started a fundamental reconstruction. A pipeline from the Belozerny gas plant to the Yuzhno-Balyksky gas plant is part of the pipeline from the Gubkinsky gas plant to the Tobolsk. It has only recently been built. A segment of the pipeline from the Nizhnevartovsky gas plant to the Yuzhno-Balyksky plant operates temporarily with line pipe not designed for it.

The 700-mm ID products pipeline from western Siberia to the Urals and Volga regions operates within the area from the loading rack at the Yuzhno-Balyksky gas plant to the Tobolsky petrochemical plant. All product pipelines lack reserve lines, remote control systems, and radio-relay communication.

Investment by Sibur in western Siberia through 2010 targets stabilizing the operation of functioning facilities and building new ones. Priority directions of the company's development activities encompassed the available infrastructure, additional sources of feedstock, and existing production and transportation system.

With an aim to achieve the selection of targeted components up to C3+ to 93% and to organize the volume of ShFLU output up to 300,000 tpy, the Gubkinsky gas plant is planning to finish construction of the first processing unit with capacity to produce 300,000 tpy of ShFLU and to finish construction of the products pipeline between the Gubkinsky gas plant and the condensate pipeline between Urengoi and Surgut.

Total 2003-04 investment amounted to about $10 million. In 2005, the company plans to spend $12 million of capital investments with a payback period of 2.5 years.

Construction of a loading rack with a commodity park near the city of Noyabr'sk to distribute ShFLU, produced at the Gubkinsky and Muravlenkovsky gas plants, will ensure a steady shipment of products at 600,000 tpy. Sibur estimates construction will cost $40 million.

An investment offer has been developed to establish a complex of facilities for ShFLU shipment from Nyagangazpererabotka. The loading rack with the products pipeline constructed at the terminal of Soim will allow the plant to produce up to 2 million tpy of ShFLU, thus ensuring output and raising economic indicators. The volume of capital investment amounts to $32 million with a discount payback period of 3.6 years.

After construction of Bakhilovskaya compressor station with a downstream Sibur gas cross-country pipeline, it will become possible to dry, compress, and transfer to the Belozerny and Nizhnevartovsky gas plants all resources of the associated gas from the Bakhilovskaya group of deposits, namely, 1.4 bcm/year. The total investment will reach $6 million, with a payback period of 1.2 years.

In 2003-04, the company spent $4 million, which allowed the Bakhilovskaya compressor station to supply 400 million cu m of gas for processing and to produce additionally 132,000 tonnes of ShFLU.

The construction of the Lokosov- skaya compressor station is to connect the gas processing plants in the Nizhnevartovsk region to the Urengoy-Schelyabinsk gas pipeline. The facility's output is 2.5 bcm/year; capital investment is $31 million.

Reconstruction and upgrading of the Yuzhno-Balyksky gas plant includes commissioning of a gas processing unit with a propane refrigeration unit. In addition, Sibur plans to finish construction of a booster plant with an increased capacity and a downstream takeaway pipeline to the Gazprom cross-country pipeline between Urengoi and Chelyabinsk.

Thus, steady processing of up to 3 bcm will be ensured with gas from Priobsky and Prirazlomny deposits, and ShFLU output will rise to 800,000 tonnes. Preliminary investments will reach 669 million rubles, with a payback period 2.4 years. At present, the final volume of investments is being assessed by the institute NIPIgazpererabotka, in Krasnodar.

Reconstruction and upgrading of the ShFLU products pipeline from the Belozerny gas plant to the Tobolsky petrochemical plant targeted to achieve the performance requirements will reduce the risk of gas processing facilities layoffs, will stabilize ShFLU production. Capital investment for 2004 reached $4 million.

Total output by West Siberia Sibur facilities with reconstruction and proposals as to additional loading taken into consideration reached $16 million for 2004 and may amount to $96 million for 2005.

Table 4 shows the total volume of the commodity output by Sibur's facilities with reconstruction and proposals as to additional loading taken into consideration.

Gazprom and Sibur are steadily developing and implementing investment projects that will permit reduction of associated gas losses in western Siberia, increase output of gas-plant products, and improve technical and economic indicators of the company as a whole.

The authors

Alexander N. Ryazanov was appointed deputy chairman of the board of Gazprom in 2001 and is currently chairman of the board of directors in JSC Sibur. In 1999 he was elected a deputy to the State Duma, the Russian Federation's Federal Assembly. He previously occupied positions as deputy chairman of the Committee for Property and deputy chairman of the Committee for Protection of Investors' Rights. In 1988-94, he was general director at Surgutsky gas processing plant. Ryazanov graduated from I.M. Gubkin Institute of Petrochemical and Gas Industry, Moscow, and All-Union Correspondence Financial-Economic Institute.

Vladimir V. Konyuchenko is deputy head of the directorate for raw hydrocarbon at Sibur, has been general director of JSC Sibur-Tyumen Gas from 2002. Since 1995 he has been director for development of the raw base and vice-president in Sibur. He has been working for 30 years in western Siberia engaged in field preparation of oil and use of associated gas. In 1974 he graduated from I.M. Gubkin Institute of Petrochemical and Gas Industry, Moscow, in design and maintenance of oil pipelines, gas storage, and petroleum storage depots.

Valery S. Plotnikov (Plotnikov @sibur.ru) is a deputy director of department of gas processing and modernization in Sibur Co. He was recently general manager of the Gubkinsky gas processing plant in West Siberia. He has also worked for 1993-96 for Poten & Partners Inc., New York. Plotnikov holds an MS in chemical engineering from Kazan Chemical Engineering Institute and MBA in process management from Azerbaijan Oil and Chemistry Institute.