ADVANCED GASOLINE BLENDING—1

A capability assessment of a North American refinery's gasoline blending system helped the company determine if it was a good candidate for upgrading to an advanced control system.

This article, the first part of two, discusses the methodology used to assess an organization's capability to implement or upgrade to an advanced gasoline blending control system from an existing installation. It also covers the strategies to sustain the long-term benefits.

The conclusion, next week, will discuss the hardware and software requirements. Both are necessary for a successful upgrade implementation and sustainable return on investment.

These articles are based on a management and technical study conducted for a mid-sized refinery in North America. The refinery has operated a basic regulatory in-line blending system for many years and wanted to know what it would take to upgrade its system to a world-class advanced gasoline blending control system—whether it would require hardware and software changes alone or organizational system changes as well.

Refiners are compelled to re-examine their gasoline blending control systems to meet the increasingly stringent local or export regulations and also to improve plant profits by minimizing gasoline quality giveaway.

Although the return on investment of upgrading either a manual system to an in-line blending system or an in-line blending to an advanced blending control system usually justifies the upgrade project, it may not produce expected results if the company is unprepared for the change. After a substantial investment in a blending project, the upgrades in the control system commonly become dormant and blend operators switch to hybrid blending methods due to a lack of commitment and support from the company.

This article discusses how management and systems in partnership can deliver improved results for the business.

Objective

The capability-assessment process was originally developed with input from strategic planners who observed that businesses frequently failed to execute a plan effectively, despite a systematic approach in planning strategies. When business strategies call for a new direction, organizations frequently fail to build the required facilities to carry out the plan.

Planning for capability assessment and capability development was developed to improve strategic performance.

The refinery in this study was interested in using the capability-assessment process to implement a plan for upgrading the blending facilities. Management felt there was an opportunity to improve profits and product quality. Previous experience with the process had led management to believe that it would be helpful in planning for improved blending performance.

This study was unique in that it combined the capability-assessment experience of a company involved in the petrochemical industry and domain expertise and experience of a company that also has developed and commissioned automation software systems for refinery blending control and optimization. Before the project started, the refinery's project management identified strategic criteria that would improve blending performance.

Team composition

A team of refinery employees met six times in 4 months. It consisted of a technical services manager who served as team leader, fuels optimization manager, pump room technician, blending supervisor, lab supervisor, IT supervisor, organization capability consultant, and a blending technical consultant.

Team members represented all the significant functions that needed to be involved to ensure a comprehensive assessment. Team members were also assigned to act as representatives for their respective functions and to communicate during the project with other group members to get complete information and build commitment to the plan.

Team meetings occurred on alternating weeks to allow enough time for project members to consider the previous weeks' output, gather information required to complete assignments, communicate with others, and get feedback.

Key result areas

Before beginning the blending-capability study, the technical consultant performed a preliminary assessment of the level of automation at the refinery and confirmed that there was a significant profit opportunity.

Refinery management reported that the key results it wanted to accomplish were to optimize financial performance of its blending operations by:

- Ensuring adequate and aligned resources.

- Meeting market demand consistently.

- Minimizing "giveaway" by maximizing octane bonus and optimizing blend economics.

- Optimizing octane supply.

- Minimizing reblending by minimizing cycle time and optimal blending to specifications.

These expectations were the basis for the organization's capability assessment. The entire process was divided in two phases—assessment and development—to achieve these goals using a systematic approach.

Phase 1—Assessment

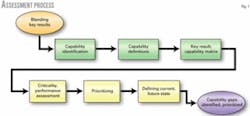

Fig. 1 shows the steps involved with the capability-assessment process. The process entails six steps.

Step 1—Identifying the required capabilities

At the first team meeting, we presented an overview to educate the team about the process and to review the refinery management's goals. The first step was to identify the capabilities required to reach the goals. The team members did this through brainstorming and discussion.

The team identified a number of required capabilities, which fell into six categories:

- Building and maintaining blend and optimization planning tools.

- Real-time availability of tank qualities.

- Accuracy of analyzer and field instrumentation.

- Adequate equipment capacity.

- Optimum manpower usage.

- Effective communication within the organization.

Step 2—Defining capabilities

Once the team identified the capabilities, we asked it to provide some specifics to define the categories. This step ensured that the team agreed about what each capability included as the team moved further along the assessment process.

This step frequently helps the team clarify what functions are covered in each capability. The capabilities are commonly revised at this point in the process; this can include consolidation, modification, or addition to the capabilities.

Step 3—Relating capabilities to key results

After the team identified and defined the capabilities, we asked it to identify which capabilities supported management's key results. This step helps check how complete the capability identification is and can also rank the importance of each capability based on the number of key results supported.

This step results in a matrix that shows the relationship between key results and capabilities. When this step was complete, the team leader reviewed the results of the team's work with management to get its feedback and concurrence with the capabilities. In this case, the discussion between the team leader and management resulted in additions and modifications to several capabilities.

Step 4—Capability assessments

The team was ready to evaluate the capabilities after completing the definitions and the key result-capability matrix. This step assigns two dimensions for each capability—importance and performance—i.e., how important each capability is to the key results area and the current level of performance.

A frequent question regarding performance is what should be the basis for comparison. The options usually are a comparison to best-in-class performance or relative to what the company needs for success. The problem with best-in-class performance is that the data of competitors' capabilities are frequently unavailable; the usual method is to use the success criteria.

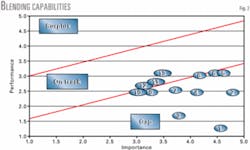

Each team member was asked to assess each capability he or she identified. When the members completed their individual assessments, the data were plotted (Fig. 2). Individual assessments allow the team members to form and express their own ideas about the capabilities.

Fig. 2 shows 13 items ranked according to performance and importance. The dissecting diagonal lines create three quadrants: surplus, on track, and gap. The team uses this plot to begin discussions.

The items for which team members' ratings varied widely are particularly important. Items with large differences are discussed and reranked. Fig. 2 shows the items numbered from the biggest gap (1) to the smallest (13).

This step is an example of a part of the process that benefited from having a technical consultant on the team. He was able to compare this refinery's level of blending automation to other companies in the industry.

Step 5—Prioritizing

Once the assessment discussion was complete, the team decided which capability gaps to address in the near term and which were sufficient for successful execution of the project. Of the 13 capabilities, the team identified eight to address in the near term to improve blending performance. The team considered five as adequate.

The team discussed extensively the interdependencies between the various capabilities. For example, a high-quality planning tool without reliable analyzers, instrumentation, and equipment capacity would not produce the desired results.

Step 6—Defining current, future state

The assessment graph and subsequent discussion provided a basic assessment; we have found that it is helpful to outline the system's current functional level and the desired future state. This helps determine the gaps that exist.

It is particularly helpful when the team discusses gaps with the management team that will eventually approve project expenditures. This step is also followed by a management review.

Phase 2—Development

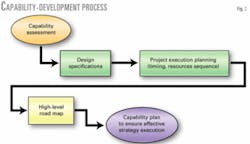

Fig. 3 shows the steps in the development process. The assessment from Phase 1 is the input for the development process. The output is a plan for what, when, and how the organization will develop the capabilities, as well as a high-level roadmap for sequence and timing.

It is important to determine what other current or anticipated projects the organization has. The team must include these in the blending plan to give a realistic estimate of when the project can be completed. It also helps to integrate all the projects.

Step 1—Design specifications

The first planning step is to build a set of design specifications. Like engineering specifications, the purpose is to identify the project's requirements.

Our experience is that when organizations attempt to improve performance and build blending capabilities, they limit their thinking to those changes they are familiar with—technology, organizational structure, or training. Our procedure is to take a total approach with design requirements to align all the components. This improves the probability of success significantly.

The components we examined to determine design requirements include process measurements, company structure and roles, information and technology, leadership, employees, rewards, and the strategy. The strategy is an input to the process.

The requirements are not necessarily identified for each category; the model serves as a check for completeness. We also have a category for other assets, which is not included here.

We asked the team to brainstorm the design requirements for each capability that members thought needed attention. For this refinery, eight capabilities needed near-term attention.

Work began in a team meeting and team members were then asked to work in subgroups and in conjunction with colleagues to develop the design requirements. The entire team reviewed the design requirements in the next meeting and each of the subgroups provided feedback.

Step 2—Project execution planning

Once the design specifications were complete, owners for detailed plans were assigned and asked to develop detailed plans for building the capabilities (Table 1).

Each action was assigned a person who would be accountable, a management sponsor, other staff resources, elapsed time required for the action, and estimated completion dates. This effort requires input from different resources and the team required additional time to complete this process.

Step 3—High-level road map

The final task after completing the detailed estimates and total time required for each of the capabilities was to develop an overall plan that scheduled the capability-development process. This blending project required 18 months of development for capital allocation, technology installation, analyzer and instrumentation design, and installation, field equipment and system tuning, and measurements. Some activities could be done simultaneously while others were sequential.

The authors

Michael J. Naughton ([email protected]) is founder and president of Navigator Management Consulting, Inc. He has 23 years of consulting experience. Since founding the company in 1999, Naughton has worked in a wide range of industries, including energy, high tech, and education. He was previously a senior consultant for Amoco Corp. Naughton holds a BA in psychology from Southern Illinois University, Carbondale, and an MS in psychology from George Williams College, Downers Grove, Ill. He is a member of the Chicago Strategic Management Association and the Human Resource Managers Association.

Suresh S. Agrawal (s.agrawal @globaloms.com) is founder and president of Offsite Management Systems LLC, Houston. He has more than 25 years' experience in developing and installing automation software products and integrated solutions for the automation of offsite operations in the chemical, and oil and gas industries. Agrawal was previously director of refinery offsite operations at ABB Industrial Systems Inc., Houston. He holds a BS in chemical engineering from Indian Institute of Technology, Mumbai, India, and a PhD in chemical engineering from the Illinois Institute of Technology, Chicago.