North Sea Pipelines-1: Extensive subsea commissioning, pigging pose challenges

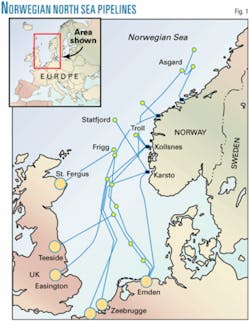

Statoil ASA has installed and commissioned about 8,000 km of subsea pipelines in the North Sea area since 1985, including several of the world’s largest offshore gas trunklines. Commissioning and pigging these pipelines presented several challenges. Fig. 1 shows the main pipelines in the North Sea.

Part 1 of this two-part series will discuss:

• Commissioning concepts for single- and multidiameter pipelines.

• Air drying of internally coated, export-gas-quality pipelines.

• Dewatering of pipelines with hydrocarbon gas.

Part 2 will examine:

• Pig design for dual-diameter pigging.

• Environmental aspects of commissioning operations.

Both parts will present relevant field experience, as well as recommendations for future projects. Part 2 will elaborate on Statoil’s commissioning concept for the 1,200-km Langeled project from Norway to the UK, scheduled for commissioning in 2006-07.

Commissioning concepts

Constraints and possibilities must be reviewed in order to establish the preferred pigging direction. For the initial flooding operation, availability of water of sufficient quality and quantity is normally the most important issue. For dewatering and later drying, two important issues decide the pigging direction: the preferred discharge location for the line-fill water and the media available for propelling the pig train.

Line-fill water is normally treated with chemicals to reduce the risk of internal corrosion in the pipeline, and environmental issues regarding discharge of the chemically treated water often dictate the direction of pigging and dewatering.

If hydrocarbon gas is available at one end of the pipeline, this will normally be the preferred method for propelling the dewatering pig train, especially if the final transport dewpoint requirement is moderate. A dewatering train comprised of pigs separated by slugs of glycol and propelled by gas will dewater and gas fill the line in one operation. When hydrocarbon gas is involved, however, a focus on safety and operational control must be maintained.

If hydrocarbon gas is not available or there are strict requirements on the transported gas dewpoint, compressed air from temporary compressors may be used to propel the dewatering pig train. The same compressors will later be used to dry the pipeline by continued purging of dry air through the line. The drawback to this method is that it requires many compressors to generate enough pressure to work effectively in large pipelines, especially in deep waters. On the other hand, air drying has proven very efficient, as will be discussed later in this article.

Following air drying, the line is normally made inert by injection of a slug of nitrogen, followed by hydrocarbon gas. Pigs are normally not used during gas filling, due to a risk of high-speed excursions during pigging at low pressures.

Other, more project-specific constraints include limited access or space for temporary equipment at one pipeline end. In some projects, one end of the pipeline may even be terminated subsea, making access difficult and costly, with divers required in shallow waters and remotely operated vehicles (ROVs) needed at greater depth.

When Statoil started developing 600-800 km gas trunklines from the North Sea to Europe in the early 1990s, the pipeline lengths were significantly beyond any addressed by the pigging and testing technology of the time. The installation of one or two intermediate pigging platforms was considered. The high cost of installing and operating such platforms, however, created incentive for developing a better pigging concept.

Extensive trials made clear that carefully designed pigs and pigging disk materials, combined with a smooth internal surface, could make pigging distances of up to 800 km feasible, and the platform concept was abandoned. Instead, Statoil decided to sandblast and apply internal epoxy coating to the pipelines to increase transport capacity and reduce pig wear. This approach also reduced the amount of mill scale and corrosion products that otherwise would have required pigging.

Drying of the pipeline after dewatering also led to major uncertainty regarding project schedule. Extrapolation from existing methods yielded unacceptable time lines, and researchers sought a better understanding of the physics involved in pipeline drying. Internal coating of the line was also beneficial in this regard, leaving less free water in the pipeline due to the smooth swabbing action of the pigs. Even with a good theoretic understanding, however, uncertainty regarding this approach led to a lack of available data for calibrating the models.

Hydrotesting such large pipeline systems posed yet another challenge. Even if steel and water are considered incompressible in certain contexts, an 840 km, 42-in. pipeline will require about 50,000 l. of added water to increase pressure by just 1 bar. There was also concern that changing seasonal currents in the North Sea would set up a corresponding temperature change that would make it impossible to obtain the steady pressure reading needed to conclude that the pipeline was free of leaks.

A 1° change in external temperature typically results in a 2-3 bar pressure change of the water-filled pipeline. A simulation model was built in which the estimated dynamic temperature profiles could be used to simulate the effects of heat transfer into the pipeline and resulting pressure changes.

In addition to the larger trunklines for transport of dry gas to Europe, Statoil also needed to transport large quantities of dense-phase gas from the Åsgard area, offshore central Norway, to the gas treatment plant at Kårstø in the southern part of the country. Offshore production facilities on a floating platform created challenges by limiting the size of export gas risers. The solution chosen for the 42-in. Åsgard Transport Pipeline was to install a subsea riser base of 28-in. pipeline valves, connected to the platform by a number of 14-in. flexible risers.

The largest valves then qualified as both retrievable and for subsea use were 28-in., but this design put large constraints on pigging.

During commissioning, pigs had to travel about 700 km of 42-in. line onshore to offshore, negotiate a short section of 28-in. line, and finally be received in a 28-in. retrievable pig trap. Operations pigs would have to perform in the opposite direction.

For complex infield production systems, Statoil prefers to use piggable loops where possible. Two pipelines running from a production template to a processing platform also give flexibility from a flow assurance perspective, and pigging can be performed from the platform rather than using expensive subsea pig traps. Sometimes, however, only a single line can be justified, and then a subsea pig trap solution is used. Such pig traps are normally stored onshore and only installed when pigging is needed.

Generally, Statoil attempts to have constant ID on all pipeline systems for pigging purposes. This applies to line pipe, valves, and fittings. A minimum bend radius of 3D-5D is also preferred. There are often compromises made, however, during design that cause the ID to vary, requiring design and qualification of special pigs for each case, thereby limiting the choice of pigs available for future use.

Air drying

Following hydrostatic testing of a gas pipeline, it is necessary (to meet the gas quality specifications and avoid hydrate formation) to remove all water prior to introducing gas when hydrocarbon gas is introduced. A bulk dewatering operation is normally performed, followed by a drying operation.

A train of mechanical pigs propelled through the line by compressed air performs the dewatering. A large number of swabbing pigs or foam pigs typically follows to remove as much free water as possible. Safe running of these pigs, however, requires back pressure in the line to minimize speed excursions, decreasing the drying efficiency. The survival of foam pigs is a concern in longer pipelines, and pig logistics can be a practical problem.

Because of this, Statoil normally includes a number of sweeping pigs, separated by air, at the rear end of the dewatering train. These pigs collect water dropping out of branch lines, etc., an important part of a successful drying operation.

Unfortunately, not all manufacturers’ pigs intended for dewatering operation are effective. This applies particularly to bend performance, in which pig geometry may result in leakage and thus leave water in the pipeline. Practical experience from coated pipelines shows that optimized bidirectional disk pigs are best suited for dewatering operations.

Following bulk dewatering and removal of the dewatering pig train, pipeline pressure has to be bled in preparation for air purging, the convection drying phase. The blowdown may take place from one or both ends of the pipeline, resulting in additional drying as the reducing air pressure allows for higher saturated water content in the air. Blowdown from the downstream end of the pipeline is most efficient, as this will be the wetter end following receipt of the dewatering train. Blowdown from the upstream end of the pipeline would result in more-or-less saturated air passing over an already dry pipeline, providing no real drying effect.

The efficiency of air drying depends on the air flow rate, air pressure, and temperature. The ability of dry air to remove free water is roughly proportional to the ratio of temperature over pressure. The air temperature will be close to the ambient temperature along the pipeline and the air pressure will decrease according to the friction loss at the flowing condition. Dry air flowing over a wet surface will pick up water and eventually reach saturated equilibrium. Varying conditions along the line create a complex pattern of evaporation and saturation.

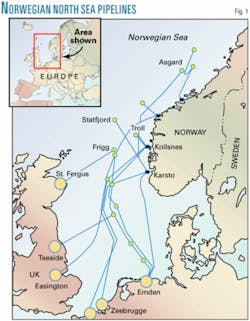

Back pressure should be kept at a minimum in order to maximize drying efficiency (i.e., air discharge should be out of the open pig trap door in the downstream end of the pipeline). Drying of the pipeline during this phase actually takes place from both ends simultaneously. The dry air introduced in the upstream end will pick up water from the wet pipe wall at the drying front, and the drying front will move downstream.

Due to the hydraulic friction along the pipe, the pipeline pressure will decrease with distance and allow for a higher water content or saturation condition. This effect increases towards the downstream end, which will result in a drying front moving towards the upstream end of the pipeline. Eventually the two drying fronts will meet somewhere in the middle of the pipeline, which is the last part to become dry. Fig. 2 illustrates this phenomenon.

The presence of puddles of water along the pipeline complicates the assessment of the drying process. A puddle may occur where there are branch lines or Ts from which water will drain back into the pipeline when dewatering pigs have passed. Efforts should therefore be taken to drain or otherwise remove water from dead ends where possible. A single puddle at one location along the pipeline is difficult to detect, as the passing dry air may not have enough time to pick up water. Small variations in water content can also be difficult to detect by downstream monitoring equipment. Hence the pipeline can be deemed dry when there is still a puddle somewhere along it.

Monitoring of the drying process is generally difficult. Ideally air purging should continue until the outlet dewpoint is equal to the inlet dewpoint. This might never be achieved, however, due to the inaccuracy of monitoring equipment. The water content of discharged air varies over a wide range, and it is necessary to mobilize different sensors to accommodate the measuring range from saturated conditions down to a typical -35º C. It is also essential to calibrate and compare the inlet and outlet sensors prior to field mobilization, as judgment is normally based upon a comparison of the two. It has been established practice to let the pipeline soak towards the end of the drying, i.e., suspend air injection and close-in the pipeline for 24 hr. The idea is that any remaining water then will be picked up by the undersaturated air and become visible when the flow of air is resumed.

This approach, however, can disrupt project schedules, particularly for long pipelines, as it takes a long time to stop and restart flowing conditions. Dewpoint monitoring equipment also often has large time constants, meaning that initial measurements after resumption of flow are unreliable.

A practical concept for long pipelines is therefore to continue drying without interruption until the difference of inlet and outlet dewpoints is less than a predetermined quantity, e.g., 5-7º C. Experience has shown that, with an inlet dewpoint of -40º C., an outlet dewpoint of -35º C. is relatively quickly achieved and that the pipeline then is sufficiently dry.

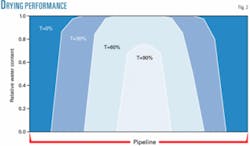

Fig. 3 shows the recorded field data from four major pipeline projects. It shows that acceptable dryness has been achieved after passage of roughly 25-30 pipeline volumes of dry air through the line. Of this, about 50% is air used for dewatering and pigging and 50% is air purged through at atmospheric outlet conditions. The water that is removed during the drying phase is equivalent to a film thickness of about 0.01 mm distributed over the entire internal surface of the pipeline.

When a large compressor spread is mobilized for pipeline dewatering, continued use of this spread for pipeline drying has proven to be very quick and cost efficient in drying dry-gas export pipelines.

Dewatering with hydrocarbon gas

The other main method used for pipeline commissioning by Statoil is a glycol swabbing pig train propelled by hydrocarbon gas. This method is mainly selected on pipelines not transporting dry gas, which therefore have less stringent dewpoint requirements, or pipelines transporting liquids or dense-phase gas.

Dewatering operations with hydrocarbon gas as a propelling medium are fast and cost effective, addressing dewatering, drying, gas filling, and pressurization in a single operation. There are, however, expanded risks. The operation needs to be properly planned and engineered and must be performed by experienced personnel.

A typical train layout would consist of six to eight pigs. The first four pigs enclose three batches of methanol or glycol. The remaining two to four pigs (optional) would run dry in order to remove as much of the liquid left behind the train as possible.

The purpose of the methanol-glycol is to replace the water film on the pipe wall. Water that passes the first pig is mixed with the methanol or glycol in the first batch. This mix enters into the second batch and is further diluted in the third batch and so on. The train is normally designed to obtain less than 1% water in the last batch.

Experience has shown that three batches of liquid are sufficient. Contingency evaluations, however, could result in four batches as a final design. It is more efficient to add more pigs to a train than to add more methanol or glycol.

Methanol was once the preferred dewatering liquid, but glycol has become more widely used. Methanol has a high vapor pressure and will be absorbed by the flowing product gas, causing potential problems for downstream users, until all liquid methanol has been removed from the pipeline.

Glycol, by contrast, has a very low vapor pressure and will for practical purposes not evaporate, remaining in the pipeline as a wetted surface. Traces of glycol in the gas are almost always present as a result of carryover from upstream gas conditioning plants. The amount of glycol left in a pipeline from a dewatering operation is normally negligible compared to this accumulated operational carry over and is therefore acceptable. Glycol is also less poisonous than methanol and therefore easier to handle.

Glycol dewatering trains are normally designed to achieve less than 1% water in the last batch. The equilibrium condition in a gas-glycol-water system in a dry-gas delivery pipeline is normally 97% glycol and 3% water; i.e., the minimum acceptance criterion could be as high as 3% water in the last batch. If 1% is obtained, the first gas produced into the pipeline will actually be further dried in the pipeline until the equilibrium condition is obtained.

Supplying gas on pressure control at normal operating pressure and performing train speed control on the water-discharge end provide control in a hydrocarbon gas dewatering system. Since the commodity between the train and the outlet control valve is a liquid, this system gives a very stable operation. Normal running speed will be 0.5-1.0 m/sec. Glycol has also proven to be a very good sealing and pig lubrication commodity, allowing minimal gas forward bypass.

Using a glycol train and gas for train propelling has proven to be extremely quick and efficient, accomplishing dewatering, drying, making inert, gas filling, and pressurization in one operation. The pipeline system is ready for commercial gas deliveries very shortly after the completion of commissioning activities.

The most complex project where glycol swabbing has been used by Statoil is the Åsgaard Transport pipeline, bringing gas from a subsea 28-in. manifold via a 700 km, 42-in. pipeline to Norway. Dewatering of this line was performed by a glycol train with compressed air as the propelling medium. Hydrocarbon gas was considered to be too risky a propellant due to this system’s dual-diameter nature. Dual-diameter pigs were developed especially for this operation and the operational experience was so good that it was concluded that the operation could have been performed with hydrocarbon gas.

The Åsgaard dewatering train consisted of six special dual-diameter pigs. That design was optimized with observed performance during previous pipeline flooding operations.

The first three pigs were equipped with transponders for tracking purposes. All pigs were equipped with a radioactive isotope to provide positive location in the receiving subsea pig trap, thereby avoiding accidental closure of the subsea 28-in. mainline valve on a pig. One pig was also fitted with an electronic gauging module to provide geometry data of the pipeline prior to start-up.

The first four pigs in the train were separated by three batches of glycol, each with a volume of about 172 cu m. The last three pigs were separated by two batches of compressed air each with a volume of 96,000 cu m. The train was then launched from the beach and displaced to the temporary pig receiver using dry compressed air with a water content of less than 0.1 g/cu m. The air injection rate averaged about 20,000 cu m/hr over the 40-day operation period with a pressure of 20-36 barg.

A surface vessel equipped with transponder detection equipment tracked the pig train through the pipeline. A computer program used to predict the main dewatering parameters backed up the tracking operation. The program was useful during both the engineering and operational phases.

For example, it showed that the train would move extremely slowly over a 5-day period at a distance of 560 km from the landfall, due to the pipeline profile. Without this prediction of the slowdown, which was also confirmed by the tracking vessel, it might easily have been interpreted as the onset of pig failure. Comparison of the predicted air pressure profile at the beach with the measured profile also provided useful confirmation of the dewatering train’s progress and integrity.

A vessel equipped with two ROVs controlled the arrival of the train and confirmed all six pigs in the head by detection of the isotopes. A subsea-operated sampling bottle arrangement took three glycol samples from each of the three batches of glycol. The higher density of the glycol and minimal over-pressure in the pipeline eliminated the possibility of a hose back to surface for sampling purposes. Once on surface, the samples were tested for water content with the following results: Batch 1, 3% water; Batch 2, 0.5% water; and Batch 3, 0.4% water. The target for the last batch was 1% water, while the acceptance criterion was 3%. The offshore test results were confirmed by a repeat analysis onshore.

The dewatering train performance was much better than expected. The pig spacing on receipt at the subsea pig trap was indistinguishable from when launched, and the water content of the three glycol batches was extremely low in comparison with previous dewatering trains that used standard pigs and methanol. This was attributed to extremely good pig performance and also to the higher viscosity of glycol as compared to methanol. A high liquid viscosity between the pigs acts like a dynamic seal, allowing decreased bypass across the pigs. ✦

Bibliography

Falck, C., Kleppe, T., and Maribu, J., “Commissioning of long subsea pipelines-environmental aspects,” Underwater Technology Conference, Bergen, Norway, Mar. 26-28, 1998.

Falck, C., Kristiansen, B., and Laxå, B., “Air drying of gas pipelines,” Pipeline Pigging Technology Conference, Houston, Feb. 3-6, 1997.

Falck, C., Svendsen, C., and O’ Donoghue, A., “Multi-diameter pigging for Åsgard: Commissioning and pigging the 710-km, 42-in. × 28-in. Åsgard Pipeline,” Offshore Pipeline Technology Conference, Oslo, Feb. 28-29, 2000.

Maribu, J., Falck, C., and Burman, P., “Åsgard gas transport system: Precommissioning and commissioning,” International Offshore and Polar Engineering Conference & Exhibition, Stavanger, June 17-22, 2001.

The authors

Christian Falck is a discipline adviser for pipeline commissioning at Statoil, Stavanger. He has also served as commissioning manager for several large pipeline projects in the North Sea. He holds an MS from The Norwegian Institute of Technology, Trondheim (1979).

Jarleiv Maribu is a senior system design engineer for the Langeled project at Statoil, Stavanger. He has also served as commissioning manager for several other large pipeline projects in the North Sea. He holds an MS from The Norwegian Institute of Technology, Trondheim, (1977).