Model predicts compositional grading of a reservoir in Iran

A study showed that an isothermal gravity-chemical equilibrium model can predict the compositional variation with depth for the Asmari carbonate reservoir in Marun field, Iran. The study was a part of a larger work for characterizing reservoir fluids for compositional simulation.

The basis of the study was laboratory pressure-volume-temperature (PVT) reports on 15 appraisal wells.

The study used a Peng-Robinson equation of state (EOS)-based PVT program, followed by a regression technique with dynamic parameter selection to tune the EOS to match PVT data. Then, the compositional gradients were modeled with an isothermal gravity-chemical equilibrium model.

The study provided good matches between data and the model.

Reservoir description

Marun field is in the central part of the Dezful embayment, a tectonically depressed area that contains the majority of Iran’s oil fields. Reservoirs include fractured and porous carbonates and sandstones of the Asmari formation of Oligocene and Miocene age and the carbonates of the Cretaceous Bangestan group. Marun field is a layered fractured limestone and sandstone reservoir.

Exploration in the field started in 1963 and production began in 1966. Production rose gradually in 1972 and exceeded 1 million b/d.

Recently production has declined to 500,000 b/d due to such problems as inappropriate production methods in new wells, excess salt-water production, leakage from the high-pressure Gachsaran formation, and imbalanced production from different layers.

Characteristics of this field include:1

• Area extent: 85 sq miles.

• Reservoir thickness: 1,000 ft.

• Original gas-oil contact: 8,370 ft subsea

• Original water-oil contact: 12,000 ft subsea.

• Average porosity: 14-24%.

• Crude specific gravity: 34° API.

• Original GOR: 900 standard cu ft/stock-tank bbl (scf/stb).

• Reservoir temperature: 218° F. at 11,000 ft subsea.

Available PVT analyses provided a way for assessing correlatable patterns in fluid properties. The study involved the calibration of the EOS for compositional simulation and established a means for predicting fluid properties for the entire area of the field.

Laboratory PVT data

The field had 15 bottomhole fluid samples from the Asmari reservoir, three of which were obtained before the start of production. The PVT reports provided information such as:

• API gravity, density, and molecular weight to C7+.

• Bubblepoint pressure at different temperatures.

• Constant composition expansion (CCE) data.

• Differential liberation data.

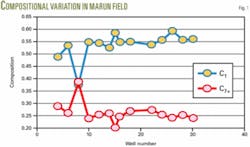

• Compositional gradients (Fig. 1).

Tuning EOS

In the study, a three-parameter Peng-Robinson (PR) equation of state was used to match all laboratory PVT data from the Asmari reservoir. This step was followed by a regression technique with dynamic parameter selection for tuning the equation of state.

Figs. 2a and 2b compare the laboratory PVT data and generated PVT data from the tuned EOS for one of the wells.

Compositional grading

Studies usually base the calculation of the compositional variation with depth on the assumption that all components have zero mass flux; in other words the components exist in a stationary state in the absence of convection.2

This study uses a balance of driving forces or flux equations to satisfy the condition of zero component net flux. The driving forces considered include chemical energy, gravity, and thermal gradient.

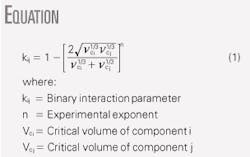

Equations 1 and 2 (see equation box) are the general equations that need to be satisfied.

In the equations, μi is the chemical potential, xi is mole fraction, Vi is the partial molar volume, Mi is the molecular weight of component i, ρ is mass density, and g is the acceleration due to gravity. Fthermal,i is the term used to compute the flux due to thermal diffusion of component i.

One can predict the variation in fluid composition and properties in a reservoir with the assumption that hydrocarbon fluids are in thermodynamic equilibrium in respect to gravity. This assumption implies that in addition to compositional and mechanical equilibrium, the temperature is constant throughout the reservoir.

In this reservoir, temperature differences are small with respect to the absolute reservoir temperature, and one may expect that an equilibrium model will give an adequate description.

Therefore, Equation 3 governs the compositional grading.

Isothermal gravity

In the absence of thermal gradients, Gibbs formal solution to compositional grading defines the condition of a system in thermodynamic equilibrium under the influence of external forces. For an isothermal assumption, Equation 4 shows this.

Integration of Equation 4 from reference depth, h0 to depth h yields Equation 5.

Model results

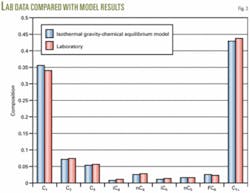

Fig. 3 shows laboratory data and the isothermal gravity-chemical equilibrium model results for components C1 through C7+.

This figure illustrates that one can predict the compositional grading in the Asmari reservoir of Marun field with an isothermal gravity-chemical equilibrium model. ✦

References

1. Saidi, A.M., Reservoir Engineering of Fractured Reservoirs, Paris: Total Edition Press, 1987.

2. Høier, L., and Whitson, C.H., “Compositional Grading-Theory and Practice,” Paper No. SPE 63085, SPE Annual Technical Conference and Exhibition, Dallas, Oct. 1-4, 2000.

The authors

Mohammad Jamshidnezhad ([email protected]) is an assistant professor of engineering at the Chamran University of Ahwaz, Iran. His research interests include production from carbonate reservoirs; enhanced oil recovery processes, and fluid flow through porous media. Jamshidnezhad holds a BS from Abadan Institute of Technology and an MS and PhD from the University of Tehran.

Mohammad Farazmand ([email protected]) is a senior reservoir engineer at the National Iranian South Oil Co. He has worked for NIOC since 1991 and his experiece is in reservoir managment, production from fractured reservoir, and reservoir simulation. Farazmand holds a BS in petroleum engineering from Abodan Institute of Technology, Iran.