New cetane index is more accurate for Canadian oil sands-derived diesels

Syncrude Canada Ltd.’s Edmonton Research Center has developed a new cetane index (CI), using laboratory data from 306 middle distillates obtained from various pilot and commercial plants that upgrade oil sands bitumen. The samples cover a wide range of boiling points and sulfur contents.

The new CI correlation requires the aniline point, the density at 15° C., and the 10%, 50%, and 90% recovery temperature by simulated distillation. It is much more accurate than the ASTM-calculated CI that uses four variable equations for oil sands-derived diesel fuels.

The new CI correlation may be applied to oil sands bitumen-derived diesel fuels from any conceivable upgrading process, untreated feeds and products regardless of sulfur content, and a wide range of boiling points, as well as to conventional crude-derived diesel fuels. It may be used as a tool for monitoring product quality and the operation of middle distillate hydrotreaters.

Background

Determining ignition quality in terms of cetane number (CN) using the engine test (ASTM D613) is costly and time-consuming; therefore, this method is not appropriate for use on a regular basis as a tool for monitoring plant operations.

The ignition quality tester (IQT; ASTM D6890) is a new tool that measures the ignition delay; some refiners may consider this tool. Most refiners, however, are still using indirect, but rapid methods such as calculated cetane index (CCI) by ASTM D4737 or their in-house developed CI correlations estimated from readily available laboratory data.

Because the Canadian oil sands projects are flourishing and production of oil sands-derived synthetic crude oil (SCO) is increasing to replace depleting conventional crude (OGJ, June 7, 2004, p. 43), oil sands-derived diesel fuel will also increase.

In general, compared to conventional crude diesel fuels, oil sands-derived diesels contain a large amount of aromatics and their CNs are low. As part of the upgrading expansion stage 1 (UE-1) project, Syncrude installed a new two-stage aromatics saturation unit specifically to reduce aromatics, and to improve the diesel CN and jet fuel smoke point.

The new aromatics saturation unit was designed to improve the product CN to 48. The CN of the diesel cut from overall Syncrude Sweet Blend (SSB) would improve to 40 from a typical 33. The new SCO will be called Syncrude Sweet Premium (SSP).

In addition to sulfur and nitrogen removal, aromatics saturation and CN improvement will become major quality control items. Monitoring the CN of the diesel cut from hydrotreated products, SSB, and SSP will become a regular activity. Use of a simple and reliable method is essential.

According to the ASTM D4737-90 adopted in 1990, the four-variable CCI was developed based on a data set of 1,229 fuels, including commercial diesel fuels, refinery blending components, and fuels derived from oil sands, shale, and coal. It is not clear how many oil sands-derived diesels were used, but they were likely coker-derived fuels from either Syncrude Canada Ltd. or Suncor Energy Inc.

There are two CI correlations in ASTM D4737-04 adopted in 2004, Procedure A and Procedure B. Procedure A is the same equation in D4737-90, and there is no explanation what data set the Procedure B equation was based on.

Syncrude installed an ebullating-bed LC-Finer hydrocracking unit in 1987 as part of the capacity addition project, and a two-stage aromatics saturation unit in 2005 as part of UE-1.

The CN of the diesel fraction from SCO therefore, was and will substantially improve compared to the diesels from earlier coker-derived SCO. We suspect, therefore, that D4737 may have a limitation when it is applied to the current and future oil sands-derived middle distillates.

Previously, Syncrude Research developed two CI correlations: one in 19911 and the other in 2000 (OGJ, Nov. 20, 2000, p. 58). The 1991 correlation was based on the density at 20° C., mid-boiling point by simulated distillation and aniline point. It fits most of the oil sands bitumen-derived diesel fuels, but appears to have limitations for the narrow cut fuels.

The 2000 correlation fits better for the narrow cuts, but it used aromatics determined by supercritical fluid chromatography (SFC) instead of aniline point. We recognized that many refiners could not get the SFC aromatics readily.

Syncrude collected 312 middle distillate samples produced from various pilot and commercial plant operations at Syncrude and other four industrial research centers, and tested the ASTM D4737 correlations. We also developed a new and better CI correlation including aniline point that fits any kind of oil sands-derived middle distillates.

Evaluated middle distillates

The 312 samples evaluated in the present study are from 18 different sources of full-range light gas oils (LGOs) and diesel cuts, and their narrow cuts prepared at Syncrude Research; and oil sands bitumen-derived diesel fuels produced at four other research centers.

The properties of the 18 full-range LGOs are the same as those used in an earlier article (first 18 columns of Table 2, OGJ, Nov. 20, 2000, p. 58). Syncrude distilled the 18 LGOs into six or seven fractions in a 15-5 distillation unit, prepared a total of 131 samples, and determined engine CN (ASTM D613), sulfur, and other needed items for evaluating the CI correlations.

Center A conducted hydrotreating experiments using a blend of virgin LGO from bitumen and LC-Finer LGO processed using a typical NiMo catalyst with varying operating conditions. It produced 72 diesel cut samples from the feed and total liquid products (TLPs), and determined all needed items, including engine CN and aniline point except for SFC aromatics.

Center B conducted two-stage aromatics saturation and hydrocracking experiments using individual feeds (virgin LGO, coker LGO, and LC-Finer LGO) and three blended LGOs with different combinations of the individual LGOs.

The blended feeds were hydrotreated with a typical NiMo catalyst in the first stage and hydrogenated over either noble metal or zeolite-type catalyst in the second-stage reactor. It produced 60 diesel cut samples from the feeds and TLPs and determined all needed items, including engine CN and some SFC aromatics.

Center C conducted one-stage hydrotreating and two-stage aromatics saturation experiments using individual feeds (virgin LGO, coker LGO, light and heavy vacuum gas oils) and two blended LGOs with different combinations of the individual feeds.

The catalysts were a typical NiMo for one-stage hydrotreating or in the first stage and a typical NiW for the second stage. It produced 39 diesel cut samples from the feeds and TLPs.

Center D conducted hydrocracking and mild hydrocracking experiments using coker heavy gas oil and heavy vacuum gas oil using typical hydrocracking catalysts. It produced 10 diesel fractions from selected TLPs for determining engine CN and other needed data.

The collected 312 samples are from a wide range of upgrading processes, boiling points, and sulfur contents.

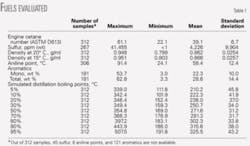

Table 1 summarizes descriptive statistics of the fuels evaluated.

Existing CI correlations

“The ASTM Calculated Cetane Index by Four Variable Equation” (D4737-04) specifies two correlations, Procedure A and Procedure B (Equations 1 and 2 in the attached equation box). Procedure A is for Grades 1-D Low Sulfur (<0.05 wt %) as well as Nos. 1-D, 2-D, and 4-D specified in D975. Procedure B is for Grade 2-D Low Sulfur (<0.05 wt %). Both equations need T10, T50, and T90 by D86 distillation.

In the past, the users who did not have the actual D86 data employed users’ own or the API correlations2 to convert simulated D2887 to D86 distillation. Now, these can be obtained from the ASTM correlations in Appendix X5 of D2887-04a.

Syncrude Research developed Equation 3 (SY CI-91) in 19911 using 185 data sets obtained from various pilot plant tests using oil sands-derived middle distillates. This correlation was successfully applied to the SCO marketing studies and pilot test programs at the research centers mentioned above; however, it was apparent that Equation 3 was not suitable for the narrow cut distillates (OGJ, Nov. 20, 2000, p. 58).

Syncrude developed Equation 4 (SY CI-00) in 2000 that also fits the narrow cuts, but it includes SFC aromatics instead of aniline point. Aromatics and aniline point are inversely related within the same oil group.1

New CI correlation

The new CI correlation that includes density at 15° C., simulated distillation, and aniline point was developed using 306 data sets out of 312 data sets investigated.

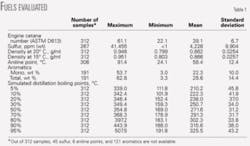

Fig. 1 shows the relationship between CN and aniline point. A good relationship exists between CN and aniline point, but only among the same oil group.

A forward stepwise regression technique in a commercial software package3 was used with the following 31 parameters as the initial inputs of the independent variables: d15, t10, t30, t50, t70, t90, AP, (d15)2, (t10)2, (t30)2, (t50)2, (t70)2, (t90)2, AP2, ln(AP), 1/AP, (AP)(d15), (AP)

(t50), (AP)(t50 - 270), (d15)(t50), (d15)(t50 - 270), (d15 - 0.86), (t10 - 220), (t30 - 250), (t50 - 270), (t70 - 290), (t90 - 320), (t70 - t30), (t90 - t10), [(t70 - 290)2 - (t30 - 250)2], and [(t90 - 320)2 - (t10 - 220)2].

The terms in semibold italics are similar forms used in the D4737 CCI Procedure A equation. The value of 0.86 in (d15 - 0.86), and 220, 250, 270, 290, and 320 in (t10 - 220)...(t90 - 320) are the rounded mean values of d15 and ti of the data sets used (Table 1 shows the mean values).

Of the 31 independent variables entered, the program selected only seven variables that gave P values less than 0.001. Equation 5 (SY CI-05) is the net result.

Testing the correlations

We tested the existing and new correlations (Equations 1-5) using the 312 fuels.

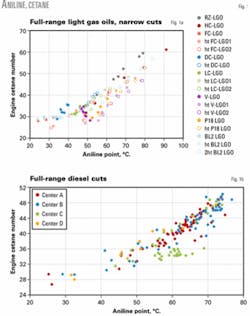

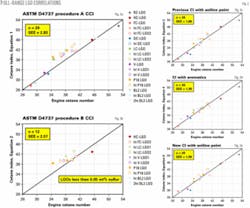

Figs. 2 and 3 show some of the results. They show the results for the full range LGOs and diesel cuts, and their narrow fractions produced at Syncrude Research, respectively.

The five graphs (a to e) in Figs. 2 and 3 correspond to the results of Equations 1 to 5, respectively. Equation 2 was tested only for the samples with less than 0.05 wt % sulfur (Grade 2-D low sulfur equivalent), as suggested in D4737 Procedure B.

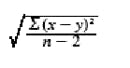

Figs. 2 and 3 also show the standard error of estimate (SEE) defined by:

where:

x = actual engine CN

y = calculated CN

n = number of data sets

The results show that:

• The SEE of Figs. 2b and 3b, which exclude the high-sulfur samples such as untreated feeds are not necessarily lower than the SEE of Figs. 2a and 3a. It suggests that Procedure B is not necessarily better for the low-sulfur samples and that oil sands bitumen-derived diesel fuels were probably not included for developing this correlation.

• The SEE of Figs. 2c-2e and Figs. 3c-3e are much smaller than that of Figs. 2a, 2b, 3a, and 3b. It suggests that Equations 3-5 are much better than Equations 1 and 2.

• The SEE of Fig. 2c is almost the same as that of Fig. 2e. This suggests that the previously developed correlation (Equation 3) is equally good as the newly developed correlation (Equation 5) for the full range LGO and diesel cut.

• The SEE of Fig. 3c is much larger than that of Fig. 3e. This suggests that Equation 3 is not suitable for the narrow cuts; Equation 5 (SY CI-05) appears to have the best fit over a wide range of boiling points.

In interpreting the data, note that we developed Equation 3 independently, not using the data sets given in the present study. The same results were obtained for the diesel samples produced at the other four research institutes, i.e., Equations 3-5 are much better than Equations 1 and 2.

We further tested the CI correlations using 16 independently prepared diesel fuels that were not included in the 312 samples.

The 16 diesel samples are:

• Four diesel cuts from two SSBs and two SSPs with different boiling ranges.

• Six diesel cuts from hydrotreated products that constitute the SSB and SSP.

• Two commercially produced mixed Middle East crude-derived diesel cuts from two different refineries in Japan.4

• Four blends of the further hydrotreated Middle East crude-derived diesel and diesel cuts from SSB at different blending ratios.4

Both CI correlations with aniline point (SY CI-05) and with SFC aromatics (SY CI-00) were better than ASTM four-variable CCIs. It suggests that the new correlation may apply to not only oil sands-derived diesel fuels, but also conventional crude-derived diesel fuels and their blends with oil sands diesel fuels.

Acknowledgments

The author thanks Steve McDougall at Syncrude Research for his helpful comments in preparing this article and Syncrude Canada Ltd. for its permission to publish it. ✦

References

1. Yui, S., and Sanford, E., “Predicting Cetane Number and 13C NMR Aromaticity of Bitumen-Derived Middle Distillates from Density, Aniline Point, and Mid-Boiling Point,” AOSTRA Journal of Research, Vol. 7, 1991, pp. 47-53.

2. API Technical Data Book - Petroleum Refining, “Conversion of Simulated (ASTM D2887) to ASTM D86 Distillation at Atmospheric Pressure,” Vol. 1, Procedure 3A3.2, 1994.

3. SigmaStat 2.0 User’s Manual, Jandel Scientific Software, Chicago, 1997.

4. Sugimoto, Y., Aihara, Y., Matsumura, A., Ohi, A., Sato, S., Saito, I., and Yui, S., “Processing of Middle East Crude with Canadian Oil Sands Bitumen-derived Synthetic Crude Oil,” to be published, Journal of Japan Petroleum Institute, Vol. 49, No. 1, 2006.

The author

Sok Yui ([email protected]) is a Senior Research Associate at the Edmonton Research Center of Syncrude Canada Ltd. His research involves quality improvement of the products from oil sands bitumen, including hydrotreating, aromatics hydrogenation, mild hydrocracking, catalytic cracking, and catalyst evaluation. Before joining Syncrude in 1979, he was section head of manufacturing coordination and planning at Mobil Sekiyu and its refining company, Kyokuto Petroleum Industries, Tokyo. Yui holds a BS, MS, and DEng from the University of Tokyo, all in chemical engineering.