Specialized steel enables deep, high-pressure completions in Tahiti field

Practical Drilling Technology

Grant Prideco LLM designed connectors that use a new steel alloy for high-pressure completions in the Gulf of Mexico. Schlumberger Ltd. used the same steel to construct a new high-pressure 7-in. perforating gun.

In April 2002, ChevronTexaco Corp. announced its discovery of the deepwater Tahiti field in the Gulf of Mexico, potentially the source of 400-500 million bbl of recoverable oil. The challenge was to design what could be the deepest and highest pressure producing oil wells in the gulf.

Water depths in the Tahiti field are about 4,000 ft and total well depths exceed 26,000 ft. ChevronTexaco operates the Tahiti project with 58% working interest; partners are EnCana Gulf of Mexico LLC (25%) and Shell Exploration & Production Co. (17%).

Completion string design

ChevronTexaco engaged Houston-based Grant Prideco in October 2002 to provide technology for completion of the discovery well and the appraisal wells. Key to success was developing the completion string that would be used for perforating and fracturing the wells.

In order to handle the fracpac completion, the well plan required a large-diameter completion tubular and new high-pressure connections. To provide material for the development of these innovative products, Grant Prideco engineers chose the Timken Co., a custom steel manufacturer based in Canton, Ohio.

Grant Prideco worked closely with ChevronTexaco engineers to quantify the loads, temperatures, and high pressures that were expected. Ultimately, Timken Impact8 steel was chosen for its combination of high strength and high-impact toughness properties after heat treat.

Impact steel has much higher toughness at ultrahigh yield strengths as well as high heat-treat response compared to standard 4140, according to Timken. The company says that Impact steel meets or exceeds the National Association of Corrosion Engineers (NACE) and American Petroleum Institute (API) standards for resistance to sulfide stress corrosion cracking at pressures greater than 95,000 psi.

According to Timken metallurgist George Waid, Impact8 alloy steel has a hardenability similar to 4140 steel, but with lower carbon content for improved toughness, sulfide stress cracking resistance, and ease of manufacturing. The Impact8 alloy includes carbon, manganese, chromium, molybdenum, and columbium (niobium).

Because the project guidelines required the same size pipe from top to bottom, it was critical to understand the pressures and stresses. Internal pressures in the string could reach 29,000 psi and external pressures could reach 25,000 psi. Compounding the problem, the compressive load at the bottom of the string could reach 215,000 lb-ft and the surface tension could reach 1,100,000 lb-ft.

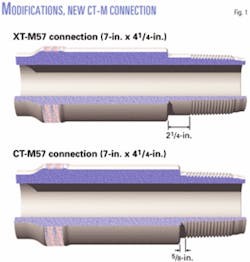

This combination of enormous pressures and loads made it imperative to ensure safety factors in the design. Although 120,000 psi is standard minimum yield strength for tool-joint connections, the requirement was raised to 135,000-psi minimum for the project-specific CT-M connection (Fig. 1). This increase in strength was accomplished without sacrificing impact toughness requirements.

Connectors

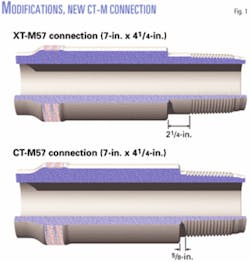

Grant Prideco performed several finite-element analyses (FEA) of its premier XT-M57 connection using ABAQUS software and "determined that it could not withstand the Tahiti loads," said Andrei Muradov, R&D manager at Grant Prideco.

They developed the new CT-M57 (7-in. x 41/4-in.) connection. According to Brett Chandler, product manager at Grant Prideco, the box counterbore is shorter (5/8 in. for the CT, compared with 21/4 in. for the XT), and the difference between the pin length and the box depth is smaller (Fig. 1). The longer counterbore length would cause the box to collapse under high compression and annulus pressures. Reducing the gap at the secondary shoulder balanced the stress in the connection and kept stresses low, according to Grant Prideco.

FEAs of the new CT-M connection showed an improvement over the XT-M connection (Fig. 2), but it was still not enough, according to Chandler. ChevronTexaco wanted a high-yield strength connection, minimum 135,000 psi. Grant Prideco's metallurgical group in Navasota ordered Timken 4130 M8 steel, tested it with a special heat treatment, and found that it met the requirements. ChevronTexaco's third-party lab in Canada (C-FER) tested and approved six sample connections made of the Impact8 steel in 2003.

Grant Prideco delivered the 57/8-in. diameter drill pipe with 1/2-in. wall and high strength CT-M57 connections to ChevronTexaco in early 2004.

Perforating gun

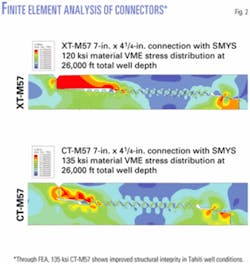

In August 2002, Schlumberger Ltd.'s Reservoir Completions Center received the initial requirements for developing an ultrahigh pressure, 7-in. diameter perforating gun system to perforate oil wells in the deepwater Tahiti development, according to a Timken press release. The gun system was required to withstand a downhole pressure of 25,000 psi and provide maximum charge performance at 18 shots/ft to optimize productivity (Fig. 3).

The new gun uses 6618 PowerFlow shaped charges containing HMX explosive at 120°/60° phasing.

Drilling history

ChevronTexaco drilled the discovery well in Green Canyon Block 640 in 4,017 ft water from the Transocean Sedco Forex Discoverer Deep Seas drill ship. The well reached TD of 28,411 ft on Mar. 29, 2002, according to a ChevronTexaco press release.

Two vertical appraisal wells with sidetracks were drilled in early 2003, in Green Canyon Blocks 596 and 640, about 190 miles southwest of New Orleans, that verified the considerable potential at Tahiti (OGJ, May 19, 2003, p. 8).

In July 2004, Schlumberger successfully perforated the first well of the Tahiti project with the new gun. In early September 2004, ChevronTexaco tested the discovery well at 25,812 ft subsea. Kathleen Arthur, vice-president of the company's Gulf of Mexico deepwater unit said that it was the "deepest successful well test in the history of the Gulf of Mexico" (OGJ, Oct. 25, 2004, p. 8). Results indicated that production could be as much as 30,000 b/d of oil.

Following the successful well test operations, ChevronTexaco says it is now actively planning the Tahiti development program to start in 2005.

Further details of the downhole technologies developed for deepwater, high-pressure completions at Tahiti will be presented at the SPE/IADC Drilling Conference in Amsterdam, Feb. 23-25, 2005.