Geothermal electric power supply possible from Gulf Coast, Midcontinent oil field waters

The rising price of electrical power and the current high price of hydrocarbons have changed the geothermal outlook in the US in a major way.

Several methods of geothermal system development previously deemed unprofitable may be viable at the present time, especially in the presence of higher electricity prices, increased or new state portfolio standards, and possible federal tax incentives.

The Gulf Coast and Midcontinent states possess few, if any, conventional electrical grade geothermal hydrothermal resources. However, states such as Texas, Louisiana, Mississippi, Alabama, and even Arkansas do possess thousands of wells that reach depths where temperatures are 250° F. to more than 400° F.

Some of these wells (or sites) are candidates for exploitation of geopressured geothermal resources, already proven feasible at prices similar to those existing today.1 Others are candidates for more conventional geothermal exploitation similar to the geothermal sites currently producing electrical power in the Great Basin of Nevada.

Still others are candidates for enhanced geothermal system (EGS) development whereby either fluid is introduced, and-or permeability is enhanced, to artificially generate geothermal reservoirs capable of sustained electrical power production (see http://www.eere.energy.gov/geothermal/egs_technology.html).

Geothermal opportunities associated with these last two situations are the subject of this article.

Many challenges

The characteristic target for initial large-scale geothermal development is EGS exploitation and has been considered to be associated with hot, deep, basement settings.

This is especially so in the western US, where commercial electrical development is currently occurring.2 3

The problem with development in this setting is that drilling characteristics, stress situations, and lithologic details remain poorly constrained and the water supply is uncertain.

Since most economic geothermal wells flow at 1,000-5,000 gpm, the probability of obtaining similar flow rates, even in stimulated bedrock reservoirs, is low, not to mention geographically restricted.

Second, the energy required to pump the fluid to the surface will generally be a significant fraction of the energy obtained by passing the fluid through a heat exchanger.

Ignoring other issues such as the availability of high background temperatures, infrastructure, and proven reservoir, the two main problems stated above are sufficient to slow the widespread use of EGS-type reservoirs and therefore the widespread utilization of geothermal electrical power production.

Thus the impediments to large-scale development are: Drilling conditions are uncertain; field development costs are high; water supplies are questionable, development costs are difficult to quantify, and, so far at least, energy companies with large capital resources are not involved.

So as currently envisaged, EGS-type situations in the western US are unlikely to generate significant electricity in the US in the immediate future.

Uncertain future

Combine the uncertainties inherent in the EGS approach, the fact that very little new geothermal exploration is occurring, the absence of involvement of highly capitalized energy companies, and the future of electrically produced geothermal energy looks uncertain.

The large-scale use of geothermal energy in the US will depend on the development of unconventional geothermal systems outside the hard rock areas of the western US. One way to increase the share of geothermal-derived electrical power is to take advantage of conditions that eliminate or at least partially mitigate limitations to development encountered in hard rock sites.

Temperatures above 300° F. are considered potentially economic with binary energy conversion systems. Therefore, the question for geothermal development needs to be: Where are such temperatures available with well (field) development costs that are more quantifiable and lower?

Fortunately, there are areas outside the western US where regional conditions lead to large areas of high heat flow and high temperatures in the crust that can be exploited commercially because of the existing knowledge base and infrastructure.4 5

By developing EGS and-or more conventional types of geothermal reservoirs in existing hydrocarbon fields, particularly in the Midcontinent and the Atlantic-Gulf coastal plains,6 it is possible to take advantage of the confluence of high-permeability engineered reservoirs, high temperatures, high flow rates, and existing infrastructure.

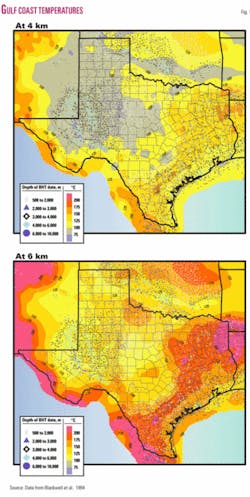

Fig. 1 is a map of the Texas state region showing areas in East Texas characterized by high temperatures in excess of 300° F. (~150° C.) at 13,123 ft (4 km; Fig. 1a) and 19,684 ft (6 km; Fig. 1b). Data from BHT and high-resolution log segments in a well from South Texas (Duval County) are shown in Fig. 2. The temperature is over 400° F. (200° C.) at 16,000 ft (5 km) and is typical of many wells in the area.

In the East Texas area (Freestone County, for example) temperatures are over 300° F. (150° C.) in the depth range of 11,000 to 13,000 ft (3.5 to 4 km). And in DeSoto Parish, northwest Louisiana, BHTs and equilibrium temperature logs document temperatures of 250-310° F. (121-160° C.) at only 10,000 ft (3 km).

Since actual in situ thermal conditions have been verified in these specific areas, it strongly suggests that the substantial areal extent of potential geothermal resources shown in Fig. 1 is in fact valid.

Conditions in hydrocarbon fields

Conventional geothermal systems

Given the existence of high temperatures, what about the producibility of large amounts of hot water?

In fact there are two typical types of existing situations associated with hydrocarbon development that are very favorable for geothermal development. The first might be considered “conventional” hydrothermal development. This situation exists in massive waterflood secondary recovery fields (Table 1).

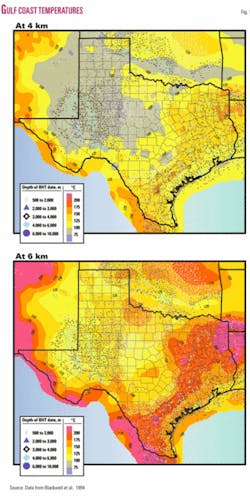

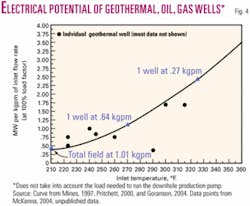

The other critical factor required for successful geothermal electrical power generation is sufficiently high in situ permeability to provide fluid flow rates equal to or greater than 1,000 gpm (kgpm). Fig. 3 shows the average total produced water by state, and the produced water cut (water-oil ratio) for 31 states.

In certain waterflood fields in the US Gulf Coast, particularly in northeastern Texas, southwestern Arkansas, and coastal Alabama-Mississippi, the produced water-oil cut is 95%. In some of these types of fields, over 50,000 b/d of fluid are produced and paid for (in terms of pumping costs) by existing operations.

Collecting and passing the fluid through a binary electrical plant would take some engineering but is a relatively straightforward process since most of the produced fluid already is passed to a central collection facility for hydrocarbon separation and water disposal.

Hence, piggy-backing on existing infrastructure should eliminate most of the need for expensive drilling and hydrofracturing operations, thereby reducing the majority of the upfront cost of geothermal electrical power production.

As an example, three counties in Arkansas and Alabama in which hydrocarbon production is presently occurring are shown in Fig. 4 along with the temperature expected at depth and the existing sedimentary blanket.

It is clear that these three counties possess high enough temperatures for geothermal electrical power generation. Most of the fluid, pumped from 10,000-16,000 ft, is at least 300° F.

The primary unknown and hence limiting factor in these three areas is the magnitude of the combined flow rates in these existing hydrocarbon fields. Since in most mature hydrocarbon fields, the disposal of produced water is a problem (i.e., expense), similar opportunities are to be found in most continental US basins.

EGS in hydrocarbon fields

The second situation exists in many of the areas developed for deep gas.

Table 2 is a comparison of needs for EGS-type development costs versus reality in existing hydrocarbon fields. It is clear that most of the up-front reservoir costs have been reduced and that the existing infrastructure can be readily adapted to geothermal electrical power production. Future work must be performed on the suitability of some of the wells-fields now being developed as deep, hot, tight sandstone gas reservoirs, but overall it appears that large areas of the Texas Gulf Coast are suitable for geothermal exploitation.

Many of these areas are hot (Figs. 1 and 2), and most are being artificially stimulated (fractured) or horizontally drilled (or both). Thus these areas are clear “EGS” types of systems but with known drilling and development costs and abundant water.

Because of the thousands of wells drilled the costs are one half to one third those for hard rock drilling and fracturing, plus a well failure usually means too much water production.

In some areas such as the Wilcox Trend in South Texas are massive sands filled with water at high temperature. In order for the EGS concept to be more than a limited success, such areas will have to be developed.

Theoretical modeling suggests that stimulations in sedimentary settings where there is some intrinsic porosity and permeability are in fact more favorable than a fractured basement rock setting.7

Production data from the hydrocarbon industry indicate that most of the hydrocarbon bearing basins and Gulf Coastal Plain in Texas, Louisiana, Mississippi, and Alabama host elevated temperatures and the potential for significant water flow (unfortunately from the present point of view of the industry).

Research into the suitability of such basin-hosted geothermal resources has been begun in the North German basin, although low formation permeability there still requires stimulating potential sandstone reservoirs and-or significant lateral drilling8

Energy production

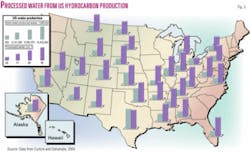

The inlet temperature necessary to obtain electrical power in binary plants is a function of wellbore flow rate and binary generator heat exchanger fluid type. 9-11

One such relationship is shown (utilizing isopentane in the secondary loop) in Fig. 4 and accounts for in-plant parasitic loss but not the energy costs of pumping the fluid from the subsurface. The calculated electrical production from several currently producing geothermal wells is also shown.

In order to generate 1.5 MW of electricity at a reservoir temperature of 300° F. a flow rate of about 1,000 gpm, or about 1,029,000 bbl/month is required. State energy records in both Arkansas and Alabama suggest that the combined flow rates for production wells in existing hydrocarbon fields in these areas is sufficient to meet the 1,000 gpm flow rate requirement.

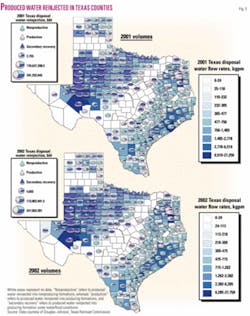

Water production from hydrocarbon production in Texas is not reported to any state agency, but the volume of reinjected (i.e., disposal) water is reported at a county level. Fig. 5 shows the volume of reinjected water in Texas counties in 2002 (the last year available from the Texas Railroad Commission at press) into nonproductive and productive formations and waterflood situations.

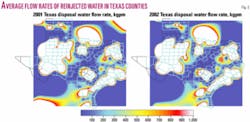

Reinjected water is considered a “nuisance” to hydrocarbon producers, but if the flow rates per county are determined (in kgpm or 1,000 gpm; see Fig. 6), then it is apparent that produced fluid flow rates in Texas are present to generate significant electrical power. Fig. 7 shows the resulting geothermally derived electrical power in Texas at 4 and 6 km if 1 kgpm is present everywhere and the relationship shown in Fig. 4 is valid.

If the Texas potential MW is spatially integrated, water produced from existing hydrocarbon fields can potentially generate at least 250,000 MW of electrical power. This averages out to about 1 MW/sq mile for the state.

Discussion

Our preliminary analysis shows that the “conventional” geothermal development may require ~30 wells/field to generate a useful flow rate in some of the more marginal temperature fields, but this estimate of the number of wells could be substantially reduced if deeper, hotter wells are utilized.

The success of the methodology however, is not critically dependent on the number of wells required to generate the flow rate since most of the produced fluid is centrally collected for separation anyway. Furthermore, production occurs at such high rates that cooling prior to heat extraction is not a concern either.

We stress that given current limitations in heat extraction technology, the success of the approach outlined above requires that the hydrocarbon fields utilized for geothermal exploitation are producing and the pumping-disposal costs are met by the production company. Otherwise the electricity extracted from produced fluids may closely equal the costs required to produce and dispose of the fluid, generating lower economic return.

We estimate that almost $4/bbl of oil revenue is utilized by production companies to meet electrical needs in high flow rate fields (i.e., waterflood fields).

If the entire volume of processed water arising from existing hydrocarbon production were run through a heat exchanger, we estimate that the combined geothermal electrical power of the 7 states nearest the Texas Gulf Coast Plain would be about 1,000-5,000 MW (Table 3). This is essentially “free” electricity as no drilling and engineering would be required to obtain the power other than the upfront cost of the turbines.

An estimate of the possible payout period is 3 to 4 years for the investment in the generation facilities.

At the present time the objective in most hydrocarbon fields is to limit water production as much as possible because it is a major expense. Fracturing and completion strategies are designed to accomplish this goal.

If there were an incentive to produce water then the existing density of drilling and the depth (temperature) of the wells is great enough that the potential power production is in the 10,000’s of MW.

The two approaches outlined above avoid most or all of drilling and wellbore stimulation costs and suggest a solution to both the desire to increase renewable-sustainable energy in the US, and a desire by energy companies to reduce the costs of hydrocarbon extraction. Hence, both the societal and economic benefits are substantial to all parties desiring an increase in US clean, renewable, electrical energy generation.

Acknowledgments

This work was supported by The Communities Foundation of Texas and a private donation by Albert Halff to SMU, and by US Department of Energy contract ID DE-FG07-02ID14414. Conversations with K. Inskeep, M. Richards, and C. Goranson substantially improved this manuscript. Director, Geotechnical & Structures Laboratory, US Army Engineer Research & Development Center, granted permission to publish.✦

References

1. Campbell, R.G., and Hattar, M.M., “Operating results from a hybrid cycle power plant on a geopressured well,” Geothermal Resources Council Trans., G14, 1990, pp. 521-530.

2.Robertson-Tait, A., and Morris, C.L., “Progress and future plans at the Desert Peak East EGS project,” Geothermal Resources Council Trans., Vol. 28, 2003.

3. Rose, P., et al., “The Coso EGS project-recent developments,” Geothermal Resources Council Trans., Vol. 28, 2004, pp. 227-232.

4. Blackwell, D. D., Steele, J.L., and Wisian, K., “Results of geothermal resource evaluation for the Eastern United States,” Geothermal Resources Council Trans., Vol. 18, 1994, pp. 161-164.

5. Blackwell, D.D., and Richards, M., “Geothermal Map of North America,” AAPG, Scale 1:6,500,000, 2004.

6. Erdlac, R.J., and Swift, D.B., “Deep permeable strata geothermal energy (DPSGE): Tapping giant reservoirs within deep sedimentary basins-An example from Permian Basin carbonate strata,” Geothermal Resources Council Trans., Vol. 28, 2004, pp. 327-331.

7. Nalla, G., and Shook, G.M., “Engineered geothermal systems using advanced well technology,” Geothermal Resources Council Trans., Vol. 28, 2004, pp. 117-123.

8. Zimmermann, G., Reinicke, A., Holl., H., Legarth, B., Saadat, A., and Huenges, E., “Well test analysis after massive waterfrac treatments in a sedimentary geothermal reservoir,” proceedings of the World Geothermal Congress, 2005.

9. Mines, G.L., Unpublished design study for binary geothermal power plants suitable for off-grid electrification projects, Idaho National Engineering Laboratory, 1997.

10. Pritchett, J.W., “Electrical generating capacities of geothermal systems,” proceedings of the World Geothermal Congress, 2000.

11. Goranson, C., unpublished data, 2004.

Bibliography

Curtice, R.J., and Dalrymple, E.D, “Just the cost of doing business,” World Oil, 2004.