Hurricane Ivan forces vigorous response and repairs

A large, concerted effort was required to reestablish Shell’s crude oil systems in the eastern Gulf of Mexico following Hurricane Ivan in 2004. Systems that were completely disabled included the transport infrastructure from Nakika, Petronius, Ram-Powell, Main Pass (MP) 289, the MP 252 complex, and Horn Mountain. The force of Ivan also hit pump stations, delivery terminals, and pipelines used to transport more than 400,000 b/d.

The hurricane struck the northern gulf on Sept. 17, 2004. It traveled in a northerly direction through the gulf and directly impacted the Nakika, Ram-Powell, and Horn Mountain production facilities. Shell’s pipeline infrastructure is the major link between these assets to Louisiana refineries and onshore distribution networks and runs primarily on the eastern side of the Mississippi River.

Mudslides, displaced debris, and currents heavily damaged the lines. Risers were severed from platforms, pipeline crossings were damaged, and pipelines were displaced in mudslide areas and sometimes fully severed. Pipelines were also hit by mooring lines from drill rigs that broke free during the storm.

Water and debris completely inundated the associated pump stations and delivery terminals along the Mississippi River, rendering them inoperable. As a part of the response effort, oil cleanup crews were mobilized to contain and pick up oil threatening the coastline.

The severity of damage required creative solutions to contain leaking oil, repair the affected systems, and return service to production facilities as soon as possible. As an example, an abandoned third-party subsea connection and associated pipeline were connected between the Shell infrastructure and a competing system in less than 2 weeks. This allowed significant production to be returned to service a full 6 weeks before the competing system was repaired.

Another challenge was the containment of oil from an offshore leak site in the Main Pass 69 area, near a wildlife refuge. The team designed and constructed a containment structure that was placed over the pipeline’s leak source under water, which allowed recovery of oil from the pipeline without allowing it to reach the surface.

Multiple work crews and vessels were dispatched to perform the repair work simultaneously. Conditions such as working on a pipeline system with two leaks at various depths, salvaging a sunken jack up boat resting on an operating pipeline, and performing a pipeline repair with 15 ft of cover were identified as major safety concerns.

Work required

Listed below are the major activities performed by the repair team to return the infrastructure to operation following the storm:

• All Shell-operated oil and gas pipelines in the eastern Gulf of Mexico were surveyed either with side scan or magnetometer equipment or with underwater remotely operated vehicles (ROVs).

• Pipeline risers at platforms in the eastern gulf were inspected with divers or ROV equipment.

• Pipeline crossings where significant movement was noted with the survey equipment or where drill rig moorings had crossed were inspected for damage.

• Two locations on the Nakika system were repaired, including one at a crossing with a third-party company that required extensive coordination.

• Two locations on the Odyssey 12-in. system were repaired, including one location with 15 ft of cover.

• A 3,500-ft section of the Delta 20-in. pipeline system upstream of the MP69 P pump station was reinstalled and reconnected to the Odyssey 20-in. line.

• A 120-ton jack up boat that was resting on the Odyssey 20-in. line in 250-ft of water was removed and brought to the surface safely.

• A subsea connection was made to the Bud 8-in. pipeline, and line integrity established, to link third-party production into the Shell system.

Repairs and cleanup were completed at the MP69 and MP69 P pump stations.

Maps similar to the one shown in Fig. 1 were used by the team to track the various work sites. All affected pipelines were pressure tested and visually inspected before returning to service.

The repairs required close coordination with the US Coast Guard (USCG), Minerals Management Service (MMS), Department of Transportation, Shell E&P and third-party producers. The Nakika 18-in. oil pipeline and the Delta system downstream of MP 69 P were returned to service on Oct. 24, 2004, while the Odyssey 20-in. system was returned to service on Oct. 30, 2004. As of Nov. 15, 2004, all crude oil flow capabilities in Shell Pipeline Co. systems were available to producers in the eastern gulf.

At the peak of the repair work, more than 24 vessels and associated crews (survey, diving, oil spill cleanup, transportation, derrick barges, etc.) were involved in the repair operations. The work conditions were extremely challenging due to the condition of the facilities after the passage of Ivan.

Survey activities

Immediately following passage of the storm, survey work was initiated on the Odyssey and Ram-Powell pipeline systems. Risers were inspected at initiating (Vioska Knoll 956, MP 252) and hub platforms (MP 289 C, MP 289 B, and VK 817). Top-tensioned risers and riser bases for Ram-Powell were also inspected to assess their integrity and were found to be in order.

In addition, a drill rig to the east of the Ram-Powell structure broke from its moorings and traveled across the Ram-Powell oil and gas export lines at four locations (Fig. 2). An ROV inspected the pipelines where mooring lines crossed them with a typical ROV inspection view (Fig. 3). The ROV completed dredging at some locations to expose the pipe for inspection.

A drilling rig also broke free of its moorings in the Nakika field. One of the ROVs was relocated from MP 252 to inspect the Nakika oil export pipeline where the rig had crossed the pipeline in three locations with its mooring lines. The inspection revealed no damage to the pipeline.

In order to ensure the integrity of the Shell eastern gulf infrastructure, survey vessels with side scan survey and magnetometer equipment were mobilized to locate the pipelines and identify any anomalies that needed to be further investigated. Additional ROV support and diving vessels also assisted in the survey efforts. Water depths encountered during the survey ranged from 10 ft to 6,000 ft, requiring a range of vessel capabilities.

More than 450 miles of survey were performed on the Shell lines east of and including the Cognac oil export pipeline. The work was conducted over a 4-week period and required close coordination between survey companies and construction vessels. Data were analyzed aboard the vessels and transported to the survey company’s home offices for further analysis. Mosaics were created on an expedited basis to determine where further ROV or diving investigation was required.

A section of pipeline also needed to be reinstalled, which required clearing an area in MP 69 to determine if third-party flowlines in the block had been relocated as a result of the storm. Survey work was performed and analyzed before restart pressure tests were conducted on the various pipeline segments.

The surveys identified the following:

• Relocated pipeline crossings.

• Pipeline displacements as a result of mudslides.

• Pipeline spans and exposures.

• Leaking gas lines very near Shell crude oil lines.

All subsea tie-in assemblies and all conventional clamped risers were intact, except for a riser at South Pass 60 which was torn from the structure.

Tooling required for the inspections included a flooded member detection tool to determine if liquids were present in the Ram-Powell gas export riser, a magnetometer array package deployed from an ROV to locate the pipeline torn from the SP 60 platform, acoustic listening equipment to determine whether a leak was present, and ROVs for inspection of mooring line crossings requiring jetting packages.

Nakika

Following passage of Ivan, a leak was discovered at the crossing of the Nakika line over a third-party oil line in 40 ft of water in MP 69. Working with the US Coast Guard and the MMS, Shell developed and executed a plan to contain the oil at the leak site and displace oil from the line so that repairs could be performed (Fig. 4).

While preparations were being made to displace oil from the line, a second leak was discovered about 15 miles upstream in 200 ft of water. A mudslide had completely severed the line at this location (MP 151). Water entering the line at MP 151 displaced oil from the line at MP 69 due to the hydrostatic pressure difference between the two leak sites.

The immediate need was to isolate the section of pipe between the two sites. The severed pipe section at MP 151 was located in a spoolpiece connection installed during original construction to tie the shallow water pipelay section to the deepwater section. Ivan straightened out the 90° elbows of the tie-in, with the spool fully severed at one point (Fig. 5). A dive crew removed the spoolpiece and installed a blind flange with a tap to isolate hydrostatic pressure from the pipeline.

At MP 69, the storm removed the concrete mats used to provide 18-in. of separation between the lines. A total of 10 concrete mats weighing 10,000 lb/mat were swept away from the site. The two lines collided repeatedly until the 2-in. protective layer of concrete on each line was damaged, ultimately creating holes in each line.

A temporary banding clamp was placed over the leak on the Nakika line at MP 69, but it did not seal off the leak completely due to the geometry of the defect.

A large pollution dome (4-ft x 4-ft x 6-ft) was installed over the leak site after positioning the banding clamp to contain the oil escaping from both the Nakika and Main Pass Oil Gathering (MPOG) lines. The dome was connected to a large response vessel and returns pumped from the top of the dome directly into the response vessel, preventing the escaping oil from reaching the water surface. A mooring system had to be established at this site to bring the response vessel near the diving support barge.

A second response vessel moved to the MP 151 site, following revisions to the repair plan. A mooring system (spring buoy) was deployed at this site to allow the response vessel to be positioned close to the diving support vessel. Water was then pumped into the line from the downstream platform (MP 69 P), displacing oil from the section between there and MP 151. Returns were taken from the pollution dome at the MP 69 leak site and from MP 151.

Pumping rates had to be adjusted so that oil captured in the pollution dome at MP 69 could be contained while other oil returns were captured at MP 151. The water slug was successfully positioned upstream of the repair site at MP 69 to isolate the leak source at the crossing. The pollution dome was then removed and the lines separated so that a temporary clamp could be positioned on the third-party line.

After placing water across the leak site at MP 69, the response vessels were disconnected and repairs began at both locations. Because the segment between MP 69 and MP 151 was still partially filled with oil, close communication between the repair spreads was maintained to avoid opening the site at MP 151 to seawater before a mechanical connector with a blind flange could be positioned on the upstream pipe end at MP 69.

A conventional spoolpiece was reinstalled at the MP 151 site with flanges and ball connectors to handle the slight angular misalignment of the pipe ends. Ivan moved the two ends, which had been offset about 30 ft, to nearly axial alignment.

Mechanical connectors and a spoolpiece with a ball connector were used to make repairs at the MP 69 site. The final tie-in of the spoolpiece at this location could not be performed until the spoolpiece at the MP 151 site was installed.

One of the more difficult tasks in preparing the pipe ends for the mechanical connectors was the removal of the adhesive used to bond the concrete coating to the fusion-bonded epoxy pipe coating. A barnacle-buster tool used to clean platform legs was ultimately used to remove the adhesive. Sanding pads were then used to prepare a smooth pipe surface for the connector installation. The line was then successfully pressure tested and returned to service.

Upon completion of the Nakika line repairs, the repair spread went to the third-party company to repair its damaged line at the crossing in MP 69.

Odyssey

Immediately following Nakika repairs, the diving support vessel working at MP 151 moved to a leak site on the Odyssey 12-in. line in MP 70. The line was deeply buried in this area due to previous mudflows. Survey results confirmed that the storm had caused additional mudflows over the line at the suspected leak site location.

A temporary banding clamp placed over the crack allowed the evacuation of oil by pumping water from the upstream platform, allowing the pipe to be cut without releasing crude oil.

Ivan also caused structural damage to the MP 289 B platform. Shell elected to abandon the pipe segment from this platform to the subsea tie-in location in MP 290. The hot-tap fitting at the subsea tie-in was removed, allowing the spur line from MP 289 C to be connected directly to the Odyssey mainline. While the entire Odyssey line was filled with water, this work and the repair in MP 70 were completed simultaneously to mitigate the status of the MP 289 B platform as a long-term concern for the system.

Attempts were made to excavate the site at MP 70 with a conventional air-lift package. The pipe was buried 15 ft below the mud line where the leak was found. The pipe body had a crack in it 4-5 in. from a structural clamp that had been installed during a previous repair.

The site was eventually excavated with a hydraulic jetting device. A 20-ft long work area was required along the pipeline axis at depth. The top of this ditch was almost 100 ft across to provide the necessary slope on its walls to ensure stability of the excavation site.

The excavation took approximately 4 days to complete.

Conventional air-lift equipment would have required weeks to jet a comparable ditch.

Once the ditch was prepared, divers connected a mechanical connector to the downstream end of the replacement section. The damaged area was removed to an existing forged mechanical connector that had been installed about 4 years earlier. A conventional spoolpiece with ball connectors was then installed between the two flange faces.

The line was successfully pressure tested and returned to service in mid-November. Similar to the Nakika repairs, this work involved the close coordination of two diving spreads simultaneously working on the line at different locations.

Delta

The 20-in. Delta loop line originates at Shell’s MP 69 pump station on the Mississippi River and extends about 5 miles northeast to the MP 69 P platform.

The line was completely severed about 3⁄4 mile from the MP 69 station. The upstream end of the failed pipe was found close to its original location, but the downstream end of the pipeline could not initially be located.

The storm had moved about 3 miles of the downstream section 2 miles to the east of its as-built location (Fig. 1). The displacement activated a breakaway connector where the Odyssey 20-in. line ties into the Delta system, putting both systems out of service.

An emergency permit was obtained to reinstall a 3,500-ft section of pipe between the MP 69 P platform and the free end of the Odyssey 20-in. line in MP 69. A pipelay barge was mobilized from Texas to install this section of pipe over a 2-week period in the second half of October. The work involved installation of the line, jetting 3 ft below the mud line, reinstallation of the spoolpiece between the pipeline and the riser at MP 69 P, hydrostatic testing of the new pipe section, and reconnection to the Odyssey 20-in. line.

The laybarge was mobilized with a complete diving spread allowing all operations to be conducted from the vessel. Several third-party pipelines in the area had also been relocated by Ivan, making the use of post-Ivan surveys essential prior to deploying anchors along the route.

The new section of line was successfully installed and the Odyssey 20-in. line successfully pressure tested by the end of October. This work allowed production flowing into the Odyssey system at MP289 C to return.

The 20-in. section of line between MP 69 and MP 69 P has not been reestablished. This work will be completed later this year.

Barge removal

Survey work on the Odyssey 20-in. line showed a large amount of debris had settled on it in MP 309.

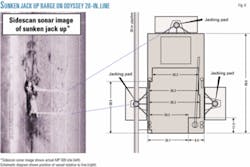

Subsequent inspection revealed that the debris pile was actually a 105-class jack up barge which sank in 1985 about 40 miles to the northwest. One of its jacking pads was resting directly on the 20-in. line pressing it below the mud line.

The remainder of the vessel was located to the north of the pipeline (Fig. 6).

A salvage company was contacted and plans prepared to remove the vessel from the pipeline. The plan called for one derrick barge to apply an upward force to the pad resting on the line, while a second lifted the vessel in a three-point configuration.

While the lifting equipment was being prepared, divers removed debris from the vessel’s deck, inspected and air lifted silt from the various compartments, and removed the jacking legs from the vessel. Three large industrial-size containers of shrimp nets and trawl boards were removed to allow installation of the lift rigging. The three jacking towers where the lift points were to be connected were also inspected for damage. The jacking tower for the pad resting on the pipeline was damaged, requiring that an alternate lifting point be designed and installed on the bow of the vessel near this tower.

The sunken barge was successfully lifted off the line and brought to the surface on Nov. 10, 2004 (Fig. 7). The sunken vessel was placed on a material barge, transported to the beach, and scrapped.

The Odyssey 20-in. line was shut down for just 6 hr while the barge was lifted off the line and set to the north of the pipeline for inspection before lifting to the surface. Shell Pipeline’s operations staff worked with producers to schedule the shutdown and minimize the impact to their operations.

Inspection of the 20-in. line immediately following the lift revealed only limited damage. The geometry of the anomalies found was analyzed to confirm that the line could be returned to its full operating pressure without a clamp.

Marlin connection to Bud

Due to the extended time frame for repairs required on the MPOG[“MPOG”?] line, BP PLC and Shell Pipeline began discussing barging operations from either the MP 225 or MP 289 C platforms. While investigating barging options, the companies discovered that an abandoned 6-in. line existed between the MP 225 platform and the 8-in. Bud pipeline that routed to the Odyssey 20-in. line via the MP 289 C platform.

This connection, if reestablished, would allow 30,000-35,000 b/d of Marlin and Neptune production to flow through Shell’s Bud and Odyssey systems. The two companies worked on a tie-in agreement as the new tie-in assembly was being fabricated for the 6-in. line.

The tie-in assembly was reestablished with the dive vessel that was working on the MP 151 location while operations at that Nakika site were suspended due to conflicting work at the MP 69 Nakika leak site. The abandoned end of the pipeline was retrieved from below the mud line at the tie-in location and a mechanical connector installed. Metrology was then taken between the mechanical connector and the tie-in assembly so that the tie-in spool could be fabricated.

While the closing spool was being fabricated, the line back to MP 225 was hydrostatically tested by BP. The closing spool was then installed and a stand-up pressure test completed from the MP 225 platform to the tie-in valve on the Bud 8-in. line.

Line-integrity monitoring was established back to Shell Pipeline’s Houston control center for the new production platforms connected to the Shell system while the subsea work was ongoing. All field work was completed in less than 2 weeks and production established from Marlin-Neptune to coincide with the startup of the Odyssey 20-in. line at the end of October.

Pump stations

The storm also disabled the pump station at MP 69 on the Delta 16-in. line. Waves and debris caused extensive damage, covering the station with marsh debris and mud up to 8 in. thick.

After removal of the debris, electrical and instrumentation equipment, as well as the station’s programmable logic controllers, were reestablished to allow operation of the station’s engines and pumps. Mechanics dewatered each engine and cleaned debris from the air intakes, changed all fluids, etc., to prevent damage upon restarting. Electricians worked to reestablish the station controls that had been destroyed.

The station was returned to service by mid-October, allowing incoming production from the Pompano 12-in. line at MP 69 to be reestablished.

Leak testing

During all repair work, close coordination was maintained with the MMS. The agency reviewed and approved repair plans for all phases of the work. Before any line was returned to service, the MMS required that a pressure test be conducted on the line during daylight hours for 2 hr without visible oil leakage present on the water’s surface.

These tests were completed on all lines with helicopter oversight flights while the lines were pressurized with oil. After each test was completed, the lines were returned to normal operations. ✦

The authors

Michael J. Coyne ([email protected]) is project manager at Shell Oil Products Distribution Engineering in Houston. He holds a master’s degree in mechanical engineering from the University of New Orleans (1988) and a BS in mechanical engineering from the University of Virginia in Charlottesville, Va. (1979).

Jason J. Dollar ([email protected]) is technical supervisor, Gulf of Mexico region, Shell Pipeline Co. LP in New Orleans. He received a BS in mechanical engineering from the University of Texas at Austin in 1991.

Based on presentation to the Offshore Technology Conference, Houston, May 2-5, 2005.