Composite materials provide alternatives for deepwater projects

Composites as a replacement for steel offer an alternative material that in many cases improves the economics for developing deepwater oil and gas resources.

These materials have the advantage of being stronger and lighter than steel, thereby reducing the loads on mobile drilling units (MODUs) and such production facilities as tension-leg platforms (TLPs). The lighter loads allow operators to extend the water depth of MODU and TLP operations.

Composite materials already present in production operations include flow lines, gratings, stairways, structural material, and fiberglass piping. Synthetic mooring lines are another alternative material that facilitates operations in deeper water. Also the American Bureau of Shipping (ABS) recently released guidelines on composite fiber-reinforced plastics (FRPs) for offshore topsides.

Other potential uses for composites include production and drilling risers, TLP tendons, as wells as cryogenic applications for LNG operations.

A recent innovation, which is an outgrowth of the work for developing composite TLP tendons, is the placement of carbon-fiber rods in umbilicals to provide additional stiffness in ultradeepwater applications.

Composite tendons, risers

TLP tendons as well as production and drilling risers become longer and heavier as projects move into deeper water, but designers can reduce the weight of these loads by substituting carbon-fiber materials for steel.

Composite risers and tendons because of their high structural damping characteristic can be immune to vortex-induced vibration that can severely fatigue steel structures, according to Mamdouh Salama, engineering fellow in upstream technology with ConocoPhillips. He has worked with composite technology since joining Conoco Inc. in 1977.

Salama notes that the first uses in the oil field for composite technology attempted to reduce the weight of loads carried in helirig operations and projects in the jungle. Originally the main users and developers of composite had been the military aircraft industry.

The cost of composites has decreased in recent years, although on a per-pound basis the cost is relatively high when compared with steel. Salama says that carbon fibers, cost about $25/lb when Conoco first started its research on composite tendons in the mid 1980s, but the material currently costs about $7/lb, which is still higher that the $0.30/lb price of steel. When one takes into consideration the lighter weight and higher strength of the composite, Salama estimates that the installed cost of a composite tendon is about the same as for a steel tendon. Composite risers, on the other hand, cost about 50% more than steel risers.

Although ConocoPhillips is no longer a partner with Aker Kvaerner in the commercial development of composite risers or tendons, the partnership in a joint industry project has qualified a composite tendon for installation on TLPs (Figs. 1-3). The prototype design is for a 1,440-m water depth in the Gulf of Mexico environment and is applicable for TLPs with a 16,600-tonne displacement, requiring 12 tethers. The tethers would include 13,500 km of carbon-fiber rods.

Available alternatives have hindered the installation of composite tendons. In Conoco’s case, Salama notes that a switch to using pipeline steel instead of expensive gun-barrel steel for tendons, as on its North Sea Hutton TLP in 1984, decreased tendon cost and made the need for composite tendons less attractive.

Also, the development of the step-tendon, which has heavier, thicker pipe sections on the bottom and larger-diameter, buoyant sections at the top, made steel tendons a good solution for deeper water. But he added that after a water depth of about 5,000-6,000 ft, composite tendons become competitive in cost because step-tendons require special fittings, forgings, and installation equipment.

Salama says that in 1998 Conoco resumed its research into composite tendons and by 2003 had developed a carbon-fiber tether similar to the parallel-strand steel rope used in suspension bridges. The manufacturing machinery for making these tendons is the same as for the suspension bridge parallel-strand steel rope, thus reducing the manufacturing costs.

Also Salama added that composite tendons, because they are solid, do not have the risk of losing buoyancy because of potential leaks that could occur in the welds of hollow steel tendons.

ConocoPhillips initially proposed to include 12-in. carbon-fiber tendons on its Magnolia TLP, but it did not aggressively pursue it because of the risk of not being able to satisfy, in time, US Minerals Management Service (MMS) requirements. The Magnolia TLP was installed during August 2004 in 4,674 ft of water with steel-step tendons. It produces oil from Gulf of Mexico Garden Banks Blocks 783 and 784.

Since then, tests at the DNV facility in Norway have pushed the tendon design to a 200-year fatigue life and 1,000-year storm conditions. Experiments that cut the tendon at increments of 10% of its diameter showed that the tendon failed only after the removal of 40% of its diameter. But the results of the tests came too late to meet Magnolia’s installation time line.

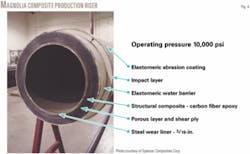

ConocoPhillips also planned to install about 600 ft (10 joints) of 113⁄4-in. composite production riser with a steel liner on Magnolia (Fig. 4). The company had qualified the composite production riser joint to 2.5 million lb tensile load and a 25,000-psi internal pressure but testing prior to the installation indicated poor welding on the inner steel liner, according to Salama. This failure, although it did not involve the composite part of the riser, prevented installation of the composite riser section on Magnolia.

Conoco has also worked on proving out the potential benefits of composite drilling risers. Starting in 2001, it drilled 11-12 wells off the Heidrun TLP wells with one joint of composite pipe at different positions in a titanium drilling riser. Salama says that the 22-in. diameter composite joint with a thin titanium liner held up well.

Cryogenic applications

Because of its thermal properties, Salama sees the next big application for composite pipe as cryogenic piping in LNG applications. For instance, composites could replace the inner and outer tubes in LNG piping that at present typically consists of a stainless steel with bellows or a Invar inner tube and a carbon or stainless steel outer tube with a vacuum separating the tubes to act as insulation.

Salama says composite piping with a zero coefficient of thermal expansion would eliminate the concern in LNG piping of thermal expansions of the inner and outer piping.

Umbilicals

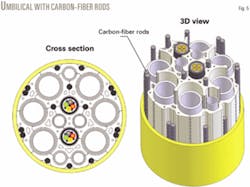

Kvaerner Oilfield Products (Aker Kvaerner Subsea) received a spotlight on new technology award at the 2005 Offshore Technology Conference for developing umbilicals with carbon-fiber rods. The rods alleviate the problem of the upper portions of an umbilical elongating as water depth increases and potentially breaking the copper electric cables within the umbilical.

The umbilical is the power and control lifeline in subsea production systems that connect the topside facilities with the subsea systems to provide utilities such as hydraulics, electric, fiber optic and chemicals.

Aker Kvaerner says that to date most companies use steel tubing to carry the weight of free hanging umbilicals with some manufacturers also using steel armour. In deeper waters, however, a heavily armoured umbilical or an umbilical dominated by the steel weight becomes counter productive. The company says that attempts to reduce elongation by adding additional steel fail because any increase in stiffness is lost by the increased weight. Deeper water, therefore, requires a stiffer and lighter material as a weight-carrying member.

Aker Kvaerner’s research and qualification tests associated with the carbon-fiber tethers led it to develop the use of carbon-fiber for enhancing the axial stiffness of umbilicals for water deeper than 6,000 ft. The company notes that fiber is far more efficient than steel because of its high stiffness to weight ratio.

Carbon-fiber rods have a stiffness of about 150,000 MPa, which is similar to steel, but the carbon-fiber rods have only 15% of the weight of steel.

The carbon-fiber rods enhance the umbilical cross-section axial stiffness by being incorporated in the umbilical with the functional elements, such as steel tubes, electrical cables, and fiber optics, at the same common lay angle (Fig. 5). The typical lay angle of the company’s umbilical is about 2°.

Aker Kvaerner says that another advantage of this design is that the rods are in direct action within the umbilical and contribute to the stiffness without any delay of break-in that is typical for other stiffness-enhancement techniques.

The first use of these umbilicals is planned for Anadarko Petroleum Corp.’s operated Independence Hub in Gulf of Mexico Mississippi Canyon Block 920. This semisubmersible facility will be moored in 8,050 ft of water and portions of the umbilicals will lie in water depths greater than 9,000 ft.

For the Independence Hub, Aker Kvaerner is manufacturing four of these carbon-fiber rod umbilicals.

Guidelines

In May 2005, ABS released guidelines for using composite-fiber-reinforced plastics (FRPs) on offshore topsides to facilitate the installation of composites. The reference provides a technical and design guide for operators that want to install FRPs in their offshore projects.

ABS says its Guide for Certification of FRP Hydrocarbon Production Piping Systems is the first publication of its kind from a classification society. The guidelines are the first of three that ABS plans to release regarding composite materials.

Its second release, which is nearing completion, covers criteria for carbon-fiber composite riser piping and joint applications. This release contains information for assessing the vertical orientation of piping from the seafloor to the floating structure, such as the required detailed analysis of the longitudinal and transverse strength of the piping for verifying whether it can withstand operating pressures.

The third release will cover composites in cryogenic piping applications. ABS anticipates that composites will have many applications in LNG operations because of its thermal properties.

DNV also has issued guidelines on composites. Its recommended practice F-202, May 2003, covers composite risers, and its OS-C501, January 2003, covers composite components.✦