Extended-reach drilling extends life of CNOOC field

LIUHUA OIL FIELD-1

China National Offshore Oil Corp. Ltd. (CNOOC) successfully used extended-reach drilling (ERD) to produce shallow carbonate reservoirs in the Liuhua oil field, South China Sea.

The Liuhua 11-1 oil field is one of CNOOC’s South China Sea assets, developed in 1995. In the first 8 years of production, the water cut increased significantly and the production decreased at an alarming level.

Without new technologies for additional drilling, production from the Liuhua 11-1 oil field would have ended in 2002. But CNOOC took steps to extend the life of the field.

In 2001, CNOOC initiated an infill ERD project to use the existing wellbore to sidetrack to the east wing of the reservoir, located about 4.5 km from the existing main facilities. Seven ERD wells have been drilled so far with excellent results.

The ERD technique has set a few records in the Chinese oil and gas industry. The B4 ERW4 well has the largest ratio of vertical section (VS) to total vertical depth (TVD) in China, 4.58. The well also ranked 10th among worldwide extended-reach wells in terms of VS:TVD ratio.

This infill ERD project has been efficient in developing the shallow satellite fields surrounding the main structure of the Liuhua 11-1 field. The success of these extended-reach wells has increased the production and extended the life of the Liuhua oil field. This first experience with extended-reach well drilling is a technical breakthrough for a Chinese oil company.

Liuhua field background

The Liuhua 11-1 oil field is in South China Sea Block 24/09, 240 km from Hong Kong. The water depth is 311 m, the deepest of any oil field in China. The field was discovered in 1987 and is the largest oil reservoir found in the South China Sea, with an estimated volume of 200 million cu m.

The shallow reef reservoir was developed by the Liuhua joint operating group, a partnership of China Offshore Oil Nanhai East Corp. (51%), Amoco Orient Petroleum Co. (24.5%), and Kerr-McGee Liuhua Ltd. (24.5%).

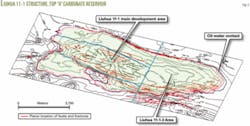

The Liuhua 11-1 structure consists of an elongate anticline bounded by faults on its northern and southern flanks.

The oil field is divided into two structures: west structure and east wing structure (Liuhua 11-1-3 area). For economic reasons, the main west structure was developed and produced first, in March 1996, by BP Amoco and CNOOC, with 25 horizontal wells from a floating production system (FPS).

Liuhua’s current offshore production system consists of three major components (Fig. 1):

• An FPS (FPS Nanhai Tiao Zhan) for drilling and producing well support.

• An innovative subsea system using electric submersible pumps (ESPs) that service 25 horizontal wells.

• A floating production, storage, and offloading system (FPSO Nanhai Sheng Li) for processing and storing the crude oil.

The developed main carbonate reservoir “A” (Fig. 2) is about 7 m thick with thin layers of oil-bearing formation with well-developed faults and fractures. The recovery rate is only 8% due to highly viscous heavy oil with strong shallow water flow through the faults and fractures. The production rate had decreased dramatically, with 90% water cut. Some sidetrack wells were drilled but the results were not significant.

The east wing of the Liuhua 11-1 oil field (Liuhua 11-1-3 area) lies 4.5 km from current Liuhua production facilities. The target formations (A, B) have a similar sedimentary and diagenetic history as the current development area. Both “A” and “B” consist of rhodolith packstones and boundstones. The reservoir properties include alternating high porosity and relatively low porosity layers.

From 3D seismic data, there appear to be fewer faults detected in the Liuhua 11-1-3 structure area. The individual development of the Liuhua 11-1-3 area, however, was proven to be uneconomical.

In April 2001, after reviewing the economics of the field, then-operator BP Amoco PLC (as BP China Exploration & Production Ltd.) initiated an infill ERD project. By using the existing subsea structure and facility, BP drilled extended-reach wells from the existing slots or sidetrack from the existing old wellbore. Beginning in 2002, seven extended-reach wells were drilled.

In July 2003, CNOOC took over ownership of the Liuhua oil field after paying $20 million each to BP and Kerr-McGee. CNOOC managed to drill the first batch of three extended-reach wells on its own: the LH11-1 C02ST1, LH11-1 A4ERW3, and LH11-1 B3ERW4 well locations were targeted at the Liuhua 11-1-3 area. The success of these extended-reach wells has increased the production and extended the life of the Liuhua oil field. This was also a first experience and technical breakthrough for a Chinese oil company in extended-reach well drilling.

Sidetracked ERW design

The feasibility study of the development design of Liuhua 11-1-3 area employs well-known drilling and completion techniques. Final selection of the ERW sidetracking scheme was based on two factors:

• Increasing the unitary economics of the field: reducing unit development cost, improving the ultimate recovery rate, and extending the economic life of the field.

• Improving drilling and completion techniques used in recent years to make ERW sidetracking possible.

Studies of the reservoir, geology, and engineering suggested several options that could be used to develop the Liuhua 11-1-3 area.

One option was to drill horizontal wells with a semisubmersible platform and then tie back to the existing main subsea system for production. A second option was to develop the three areas with satellite platforms and tie the subsea system back to the FPS platform. A third option was to add more subsea wellhead and umbilical systems to the current subsea system.

The investment costs of each of these options would overrun the budget; none of the three options was economic. These options were not recommended because of the high cost associated with the additional subsea equipment, tie back operations, and future ESP replacement.

Utilizing the existing subsea slots and drilling rig and ERW drilling techniques to develop Liuhua 11-1-3 area proved an economically efficient solution after economic analysis and evaluation. Sidetracking from the existing drilling slots with ERW techniques will not add any subsea wellheads or umbilical systems and will not require CNOOC to upgrade the existing producing and processing facilities. With ERW drilling techniques it is feasible to drill 6,000-m extended-reach wells with good results.

Well path design

CNOOC followed a basic design for ERW sidetracks using current subsea slots. The well path design included: kick off, first buildup section, tangent section, second buildup section, horizontal section (production hole), implemented as follows:

1. Pull the subsea christmas tree and retrieve the existing production string.

2. Cut and retrieve the 95⁄8-in. OD casing and the 133⁄8-in. OD casing; prepare to kick off new hole.

3. Drill the 171⁄2-in. openhole section and set 133⁄8-in. OD casing. The 171⁄2-in. openhole section has a high buildup rate.

4. Drill the 121⁄4-in. hole section to the top of “A” limestone. Run 95⁄8-in. OD casing with a Davis flotation collar (to counteract torque and drag, and to prevent buckling). The 121⁄4-in. openhole section is a tangent section with a high inclination angle, and the top of “A” limestone is the setting point of the 95⁄8-in. OD casing.

5. Build up to 89º and enter into the production zone, drill 81⁄2-in. horizontal section in the production zone to TD of the well.

6. Complete the well with openhole completion, install ESP unit, and install 5.0-in. OD production tubing for artificial lift.

7. Start up ESP unit for cleanup and hand over the well to production after well test.

The basic design included a contingency plan:

• Apply a running 7-in. liner and drill a 6-in. hole as backup in the event of failure in setting 95⁄8-in. casing into the top of “A” zone.

• Run and cement a 7-in. liner into “A” layer (casing point), drill a 6-in. horizontal hole to the revised TD with a 6-in. openhole completion.

• Run an ESP into 95⁄8-in. casing and hand over to production. (The shale zones above “A” limestone that are not isolated by 95⁄8-in. OD casing will cave in during future production.)

This basic design has already been proven in drilling and has formed the guidelines for ERW sidetracks in the Liuhua oil field.

Challenges in extended-reach wells

1. The sidetracked extended reach wells were drilled and completed from a semisubmersible platform. The project involved a complex subsea wellhead and umbilical system and was subject to severe weather and sea conditions, with frequent typhoons.

2. The selection of subsea slots is limited. The design and execution of sidetracked ERWs must prevent hole collisions.

3. The reservoirs are shallow (about 900 m below mud line) and the well trajectory is restricted by a thin oil layer and strong bottom water.

4. The well paths have a shallow kickoff point into a soft formation, a high build up rate, and a long buildup rate section.

5. Well path control is challenging because of the long tangent section, high inclination angle, and high tortuosity. The threshold dogleg severity around the ESP setting depth is 1°/30 m.

6. Seawater is used as the base drilling fluid; hole cleaning and solids control much more difficult with water-based mud and affects the torque and drag.

7. There is obvious casing wear through the long openhole section, and running casing through this section is difficult.

8. The well design requires reliable top drive and circulating systems, and puts high load stress on aged drilling tools and equipment.

9. The subsea manifold leaks, which prevented the well from being produced after it was drilled.

10. Additional detailed geological and reservoir studies need to be performed and more sensitivities need to be run to improve future drilling results.

The conclusion of this article, including details of the well design, drilling parameters, casing program, and tools used in the Liuhua drilling project, will be published in the Aug. 8 issue of OGJ. ✦

References

1. Zhang, Wu Nian, “Xijiang To Create ERD World Record In South China Sea,” Oil Drilling & Production Technology (Chinese), 1998, Vol. 20 (supplement).

2. Zhang, Wu Nian, “95⁄8-in. Casing Cementing Technologies,” Oil Drilling & Production Technology, 1998, Vol. 20 (supplement).

An earlier Chinese version of this article appeared in Oil Drilling & Production Technology magazine, Vol. 27, No. 1, January 2005.

The authors

Wei Hong An (weihan@ cnooc.com.cn) is technology supervisor for the drilling department of CNOOC Ltd.-Shenzhen, Shenzhen, China. He is also the deputy drilling manager of the Liuhua ERW drilling project. Wei holds a BS in petroleum engineering (development) from the South West Petroleum Institute, Sichuan, China (1995). He is a member of the Chinese Petroleum Society.

Tang Hai Xiong (tanghx@ cnooc.com.cn) is the manager of the drilling department of CNOOC Ltd.-Shenzhen, Shenzhen, China. He holds a BS in engineering (1983) from Jiang Han Petroleum Institute, Hubei, China, and is a member of the Chinese Petroleum Society.