Various factors affect reefing decisions

Rigs-To-Reef—1

Operators that donate obsolete platforms to the Louisiana and Texas artificial-reef programs in the Gulf of Mexico often can lower decommissioning costs.

While literature has much information on the science and benefits of artificial reefs, only limited information exists on rigs-to-reef programs and their economics. Many factors influence the decision to convert a rig into a reef and, subsequently, the cost savings associated with reefing.

This first in a series of three articles describes the various decommissioning options. The remaining two parts will cover in more detail the economics and scope of the Louisiana and Texas programs.

Structure benefits

Offshore platforms in the gulf are important for both the recreational and fishing industries and are recognized as de facto artificial reefs.1-3 Shortly after the installation of an offshore structure, sessile invertebrates such as barnacles, oysters, mussels, and sponges attach to the underwater frame. These organisms attract mobile invertebrates and fish species that in turn attract larger fish that feed on them, forming a highly complex and interrelated food chain.

The removal of the offshore structure ashore, however, eliminates the artificial reef habitat, affecting severely the associated biological community. But the degree to which artificial reefs attract and produce fishery resources is still a matter of scientific debate.4-6

Currently in use in the federally regulated Outer Continental Shelf (OCS) of the gulf are almost 4,000 structures and 33,000 miles of pipelines. The types of structures and configurations vary widely, depending upon the age of the structure, reserve size, proximity to infrastructure, operating methods, economics, and strategic considerations.

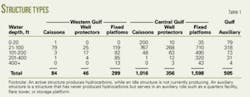

Shallow water developments typically employ caissons, well protectors, and fixed platforms (Fig. 1). Table 1 categorizes the structures according to type, water depth, and planning area.

Since 1947, when offshore production first began in the gulf, the industry has removed more than 2,200 structures from federal waters. The number and type of structures removed varies considerably from year to year but during the last decade about 125 structures/year were removed.

Reef programs

Many early manmade reefs used materials of opportunity such as boxcars, tanks, ships, tires, construction rubble, oyster shell, etc. These materials (except ships) mostly have little long-term success as reefs because storms easily break them up or move them.

The gulf’s first offshore structure disposed of as an artificial reef was a 2,120-ton subsea production system. The disposal occurred in 1979 after the structure was towed from Louisiana to a site off western Florida.7

During the next few years, the industry placed several more structures at various sites, and in response the US Congress passed the National Fishing Enhancement Act (NFEA).

In 1984, President Reagan signed the NFEA (Title II of Public Law 98-623) to “promote and facilitate responsible and effective efforts to establish artificial reefs... constructed or placed for the purpose of enhancing fishery resources and commercial and recreational opportunities.”

The NFEA consolidated several decades of local and state laws and directed the National Marine Fisheries Service to develop the National Artificial Reef Plan to serve as a guide to state artificial-reef programs.8-10

The NFEA mandated the Secretary of Commerce and other support groups to develop a long-term plan for siting, constructing, permitting, installing, monitoring, managing, and maintaining artificial reefs within and seaward of state jurisdictions.

Different government bodies regulate offshore structure decommissioning and abandonment. State agencies regulate the activity in state waters, while the US Minerals Management Service (MMS) regulates structures in federal waters.

The regulations published in 30 CFR Sect. 250.1703 provide the general requirements for decommissioning structures in federal waters.11 They state that operators have 1 year after the lease or pipeline right-of-way terminates to plug and abandon all wells permanently, remove all platforms and other facilities, and clear the seafloor of all obstructions created by the operations.

Typically, a lease terminates when production on the lease ceases, but MMS may grant an exception to maintain structures on a non-producing lease.

Decommissioning decisions

Decommissioning decisions involve issues of environmental protection, safety, cost, and strategic opportunity. The factors influencing the timing and manner of removal are complicated and depend on technical requirements, costs, preferences of the contractor, and federal regulations.

The decision to reef a structure is one alternative. Cost is a primary deciding factor. If removal option X has an expected cost of E[C(X)], than removal option A is preferable to option B if E[C(A)]< E[C(B)], as long as all other factors are equal.

Other factors to consider include the expected duration of the operation, perceived risk, past experience, and historical relationship between the operator and state.

A typical decommissioning involves the oil and gas processing equipment and piping being taken ashore for refurbishment and reuse, selling as scrap, or disposal in an approved landfill.

Companies typically recycle piling and conductors but have few opportunities for reusing topsides equipment because of its age, corrosion, and changes in technical standards.12-14 Usually they store ashore for reuse or scrap such material such as braces, bridges, heliports, and miscellaneous steel.

Deck and jacket structures have more options for disposal, such as scrapping, reinstallation at a new location, or conversion to an artificial reef. Since initiation of the rig-to-reef programs, the industry has scrapped about 80% of the removed structures.15 Also it has refurbished and reused about 10-20% of the decks and less than 10% for jackets. Most structures are sold for scrap and recycled.

Because of their configuration, decks generally are easier to reuse than jackets and also are easier and cheaper to scrap. Decks are rarely used as reef material.

Jackets, on the other hand, are suitable for artificial reefs because of their size, shape, design, and density.2 16 The open jacket structure allows water to circulate and provides easy mobility for fish. This attracts not only bottom-dwelling fish but also mid to top-water dwellers.

Steel jackets are one of the most stable and durable reef materials available.

Decommissioning stages

After completion of project engineering and cost assessment, a decommission project requires federal and state regulatory permits for plugging and abandoning wells, pipeline abandonment, structure removal, and site clearance verification.

The project will include flushing and cleaning processing components, installing padeyes, pigging and flushing pipelines and risers, detaching risers from the structure, and capping the lines. Companies normally leave pipelines in place with the ends buried 3 ft below the mudline.

The core of every decommissioning project and most expensive stage is the removal of the structure.17 The work encompasses lifting modules off the deck, cutting and removing the deck, and cutting and pulling out the conductors and piles. Heavy-lift vessels move the jacket for disposal.

After the structure is removed, trawling vessels or a diver deployed with side-scan sonar verify site clearance. For structures donated in situ, the regulatory agency may waive the requirement of site clearance and verification surveys.

References 18-23 provide various case studies on rigs-to-reef projects, while References 24-26 provide a comprehensive overview of the technical requirements for decommissioning. Broader discussions of rigs-to-reef program and decommissioning can be found in References 1, 9, 23, and 27-30.

Decommissioning generally consists of:

• Cutting the deck from the jacket with torches and than placing it on a cargo barge (Fig. 2).

• Clearing mud from the pile interior with water jets so that the platform legs can be cut 15 ft below the mudline with explosives or other cutting device. If the pile interior is blocked, jetting is used to clear mud from around the piles to accommodate an external cutting device. Explosives frequently cut piles or companies also can employ abrasive water-jet technology (Fig. 3).

• Severing and removal conductors while plugging and abandoning the wells or during structure-removal operations. The cutting can include mechanical casing cutters, abrasive water jets, or explosives. Success and economics of the operation depend on the technology selected.31

• Lifting the jacket structure from the water and welding it to a materials barge for transport ashore or a reef site. Other possibilities include toppling the jacket in-place after cutting the piling or cutting the jacket in half with the top half toppled (Fig. 4). Partial removal operations usually involve abrasive or mechanical cutters when regulations prohibit the use of explosives.

Legislation

All five states bordering the gulf have artificial-reef programs, but only Louisiana and Texas rely almost exclusively on oil and gas structures for reefs.

The Louisiana and Texas programs have placed almost 200 structures in artificial reefs.

Alabama, Florida, and Mississippi have prolific reef programs but have only accepted a few oil and gas structures.

Louisiana in June 1986 became the first state to create an artificial-reef program under the guidance of NFEA and the authorization of the Louisiana Fishing Enhancement Act (100-1986).32

In 1989, the Texas legislature directed the Texas Parks and Wildlife Department to develop the artificial-reef potential offshore Texas. In 1991, the department published the plan as Texas Parks and Wildlife Code, Chapter 8-9 (Section 89.001-89.0061).33 34

Permit agencies

The MMS will waive the 1-year structure removal requirement to accommodate conversion of a structure to an artificial reef provided that:

• The structure does not inhibit future development opportunities.

• The resulting artificial reef complies with the US Army Corps of Engineers (COE) permit requirements and procedures outlined in the national artificial-reef plan.

• A state fishing management agency accepts liability for the structure.

COE grants a permit to site a structure as an artificial reef under Section 10 of the Rivers and Harbors Act of 1899 (33 USC 403). The COE reviews the operation, inspects the materials, and then issues the appropriate permit or makes recommendations to improve the permit application.

The US Coast Guard (USCG) is responsible for the safety of vessel traffic and has the authority to dictate aids to navigation for obstacles in the water.

Aids to navigation

USCG classifies artificial reefs as obstructions to navigation that must be marked in accordance with district guidelines.

In general, three factors determine marking requirements:

1. Distance from navigation fairways.

2. Diameter of the reef complex.

3. Minimum clearance between the top of the reef structure and the water surface.

The USCG district commander determines on a case-by-case basis if markers are required and their type, number, and description.32

Obstacles deeper than 200 ft typically do not require aids to navigation. Obstacles in 85-200 ft of water require unlighted buoys, while obstacles protruding through the surface require lights or lighted buoys and foghorns.

Liability

MMS may release a platform operator from removal obligations if a state agency for managing fisheries resources accepts the liability.

The state assumes ownership of the artificial reef and has responsibility for the cost of buoy construction and replacement, operation, and any other liability issues. Artificial reefs attract residual liability in perpetuity or until the marine environment dissolves the steel structures.

The Louisiana Department of Wildlife and Fisheries and the Texas Parks and Wildlife Department serve as the agent for the state.

Donations

Companies that donate a platform as an artificial reef can often lower the decommissioning cost below the cost of bring the platform ashore. The usual practice is for the state and operator to split the savings realized.

A third-party cost estimate for removal alternatives prior to the work is the basis for negotiating the cost savings.

If the expected cost to remove a structure to shore is E[C(Shore)], and the expected cost of reefing is E[C(Reef)], then the expected cost savings is E[C(Shore)] - E[C(Reef)]. A large and positive expected savings indicates that the structure likely will be placed in an artificial reef.

Companies usually use a turnkey (lump sum) basis for decommissioning work and therefore the contract may include a risk premium to cover a decision to reef a structure because an operator cannot adjust the donation for unforeseen circumstances.

Cost estimates

Several factors affect the cost of converting a rig into a reef and, subsequently, the cost savings associated with reefing. These factors include the size, location, water depth, method of removal, and proximity of the platform to the permitted reef site. Environmental, engineering, and market conditions introduce additional uncertainty.

The size and weight of a structure determine the construction equipment required for the operation. Water depth and lift capacity of cranes influence the derrick barge (DB) required while cutting methods affect the maximum load weights expected.

In shallow waters, the deck is normally the heaviest lift, while in deep water, the jacket weight normally exceeds the deck weight.

Decommissioning costs generally increase with the complexity of the structure and water depth at the site,17 and therefore, one would expect that a lower average donation for three and four-pile structures than for eight-pile structures, with all other things equal.

Location is important because it determines the distance to a shore support facility, water depth, and distance to the nearest reef site.

Distance to shore is important because longer distances increase the costs for transportation and related service. Tow distance to the nearest reef site is important because longer distances imply less cost savings for placing a structure in a reef.

Onshore disposal of a structure ashore is almost always more cost effective if the structure is in water shallower than 100 ft. Deepwater decommissioning frequently involves partial removal and toppling-in-place. Structures towed to site usually contribute less than the partial removal and topple-in-place option because of the towing expense.

Towed structures have a greater probability of providing no cost savings because of weather or other delays.

Structures in deeper water have a greater size and weight, and therefore higher decommissioning costs and less operational flexibility because of such factors as diving operations becoming more expensive because of the limited diver time underwater, more exposure to weather, etc.

The USCG requires a minimum 80-90 ft clearance between the top of a reefed structure and the water surface.

The cost of a partial removal relative to the topple-in-place option depends upon site-specific conditions. In a partial removal, the jacket is cut in the water column, while the piles are left in place.

Water column cuts require mechanical and abrasive cutters and, frequently, the use of divers that generally cost more and have a greater human safety risk than explosive techniques. The work generally tolerates worker exposure to low-level risks during long periods, but offshore construction tries to avoid high-level, short-term risks.

Engineering considerations, a contractor’s experience, and considerations for a successful operation determine the likely cost savings and risk for a project. Also this work is sensitive to weather and ocean conditions. Wind, waves, current, and weather affect operations throughout the year, especially during the hurricane season (June 1-Nov. 30). The winter season (Nov. 30-Mar. 1) also has elevated sea states that may delay work.

Technical complications and other conditions also may delay operations. For instance, the use of explosives requires that the water column and general vicinity of the structure is clear of mammals and sea turtles prior to detonation.

Market conditions, and the demand for and supply of lift boats, DB spreads, cutting spreads, diving support vessels, etc. influence not only the cost of the service but also the time when the operation commences.

Acknowledgments

The author thanks Rick Kasprzak, Louisiana Artificial Reef Program, and Douglas Peter, Texas Artificial Reef Program for their help with this series of articles. These articles were prepared on behalf of the MMS Gulf of Mexico OCS region but have not been technically reviewed by the MMS. The opinions, findings, conclusions, or recommendations expressed in these article are those of the author and do not necessarily reflect the views of the MMS. The MMS provided the funding for this research. ✦

References

1. Dauterive, L., Rigs-to-reefs, policy, progress, and perspective, MMS 2000-073, US Department of the Interior, MMS Gulf of Mexico OCS Region, New Orleans, 2001.

2. Harville, J.P., “Obsolete petroleum platforms as artificial reefs,” Fisheries, Vol. 8 (1983), No. 2, pp. 4-6.

3. Reggio, V.C. Jr., Petroleum structures as artificial reefs: a compendium, OCS Study MMS 89-0021, US Department of the Interior, MMS Gulf of Mexico OCS Region, New Orleans, 1989.

4. Stanley, U.R., and Wilson, C.A., “Factors effecting the abundance of selected fishes near petroleum platforms in the North Gulf of Mexico,” US Fishery Bulletin, Vol. 89 (1991), pp. 149-159.

5. Carr, M.H., and Hixon, M.A., “Artificial reefs: the importance of comparisons with natural reefs,” Artificial Reef Management, Vol. 22 (1997), No. 4, pp. 28-33.

6. Pickering, H., and Whitmarsh, D., “Artificial reefs and fisheries exploitation: a review of the ‘attraction versus production’ debate, the influence of design and its significance for policy,” Fisheries Research, Vol. 31 (1997), pp. 39-59.

7. Kasprzak, R.A., “Use of oil and gas platforms as habitats in Louisiana’s artificial reef program,” Gulf of Mexico Science, Vol. 1 (1998), pp. 37-45.

8. Meier, M.H., “A debate on responsible artificial reef development,” Bulletin of Marine Science, Vol. 44 (1989), pp. 1051-57.

9. Murray, J.D., “A policy and management assessment of U.S. Artificial Reef Programs,” Bulletin of Marine Science, Vol. 55 (1994), No. 2-3, pp. 960-69.

10. Stone, R.B., “National artificial reef plan,” NOAA Technical Memorandum NMFS-OF-6, National Oceanic and Atmospheric Administration, National Marine Fisheries Service, Washington DC, 1985.

11. Federal Register, 67(96), 35398-35412, US Department of Interior, MMS, 30 CFR Parts 250, 256, Oil and Gas and Sulphur Operations in the Outer Continental Shelf - Decommissioning Activities; Final Rule, May 17, 2002.

12. Gibbs, B., “Offshore structure abandonment: solutions for an aging industry,” Sea Technology, April 2000, pp. 25-32.

13. Terdre, N., “Reuse in focus as decommissioning market develops slowly,” Petroleum Review, Vol. 54 (2000), pp. 22-23.

14. Van Voorst, O., “Offshore facility re-use - a viable option,” Petroleum Review, Vol. 53 (1999), pp. 38-39.

15. Kaiser, M.J., and. Mesyanzhinov, D.V, “Idle iron in the Gulf of Mexico,” OGJ, Jan. 3, 2005, pp. 29-33.

16. Reggio, Jr., V.C., “Rigs-to-reefs: the use of obsolete petroleum structures as artificial reefs,” OCS Report/MMS 87-0015, MMS Gulf of Mexico OCS Regional Office, Metairie, La., 1987.

17. Kaiser, M.J., et al., “Study estimates Gulf of Mexico decommissioning costs,” OGJ, Oct. 3, 2003, pp. 39-47.

18. Hakam, A., and Thornton, W.L., “Case history: decommissioning, reefing, and reuse of Gulf of Mexico platform complex,” Paper No. OTC 12021, Offshore Technology Conference, Houston, May 1-4, 2000.

19. Kasprzak, R.A., “Neither gone nor forgotten,” Louisiana Conservationist, Vol. 51 (1999), pp 4-7.

20. Moritis, G., “New option lets operators eliminate facility disposal liability,” OGJ, June 22, 2002, pp. 39-41.

21. Parker, M.E., and Henkhaus, E.J., “High Island A-343 ‘A’ and ‘B’: A case history of offshore platform abandonment and artificial reef planning,” Paper No. SPE 19709, SPE ATCE, San Antonio, Oct. 8-11, 1989.

22. Perry, A., et al., “Amoco Eugene Island 367 jacket sectioned, toppled in place,” Offshore, May 1998.

23. Quigel, J.C. and Thornton, W.L., “Rigs to reefs - a case history,” Bulletin of Marine Science, Vol. 44 (1989), pp. 799-806.

24. Manago, F. and Williamson, B. (Editors), Proceedings: Public Workshop, Decommissioning and Removal of Oil and Gas Facilities Offshore California: Recent Experiences and Future Deepwater Challenges, , MMS OCS Study 98-0023, September 1997.

25. Pulsipher, A.G. (Editor), Proceedings: An International Workshop on Offshore Lease Abandonment and Platform Disposal: Technology, Regulation, and Environmental Effects. New Orleans, 1996.

26. National Research Council, Marine Board, Committee on Techniques for Removing Fixed Offshore Structures, “An assessment of techniques for removing offshore structures,” National Academy Press, Washington DC, 1996.

27. Baine, M., “Artificial reefs: a review of their design, application, management and performance,” Ocean and Coastal Management, Vol. 44 (2001), pp. 241-59.

28. Hamzah, B.A., “International rules on decommissioning of offshore installations: some observations,” Marine Policy, Vol. 27 (2003), pp. 339-48.

29. MacDonald, J.M., “Artificial reef debate: habitat enhancement or waste disposal,” Ocean Development and International Law, Vol. 25 (1994), pp. 87-108.

30. Schroeder, D.M., and Love, M.S., “Ecological and political issues surrounding decommissioning of offshore oil facilities in the Southern California Bight,” Ocean and Coastal Management, Vol. 47 (2004), pp. 21-48.

31. Kaiser, M.J., et al., “The science and technology of nonexplosive severance techniques,” Marine Technology Society Journal, Vol. 38, No. 1, Spring 2004, pp. 29-38.

32. Wilson, C.A., and Van Sickle, V.R., “Louisiana state artificial reef plan,” Louisiana Department of Wildlife and Fisheries, Technical Bulletin, Vol. 41 (1987), pp. 1-51.

33. Shively, J.D., et al., “The Texas Artificial Reef Program: over 50 years of marine habitat enhancement in the Gulf of Mexico,” Management Data Series, No. 196, Texas Parks and Wildlife Department, Coastal Fisheries Branch, Austin, 2003.

34. Stephan, C.D., et al., “Texas artificial reef management plan,” Management Data Series No. 3, Texas Parks and Wildlife Department, Coastal Fisheries Branch, Austin, 1996.

The author

Mark J. Kaiser ([email protected]) is an associate professor-research at the Center for Energy Studies at Louisiana State University, Baton Rouge. His primary research interests are related to policy issues, modeling, and econometric studies in the energy industry. Before joining LSU in 2001, he held appointments at Auburn University, the American University of Armenia, and Wichita State University. Kaiser holds a PhD in industrial engineering and operations research from Purdue University.