Drilling Market Focus: Chinese build rigs, drillers venture abroad

China’s increasing industrialization is expanding its drilling market. The need for petroleum is driving increased drilling and Chinese yards will build more than 100 new land rigs this year.

Rig counts

Without relying on outright disclosure, it’s difficult to estimate the number of land rigs working in China at any given time. Operators report regionally, rather than nationally, and there is a host of separate administrative bureaus and regional authorities apparently without centralized record keeping that is publicly available. Land rigs in China are owned by national and regional drilling companies; only rarely are any leased from outside the country.

China National Petroleum Co. reports that subsidiary Great Wall Drilling Co. Ltd. has 618 rigs: 107 (720 hp), 287 (1,000 hp), 197 (1,500 hp), 26 (2,000 hp), and 1 (3,000 hp).1

In his Oil Service Topical Report issued in early June, Dan Pickering suggested that CNPC’s global land fleet may contain more than 700 rigs, with more than 100 of these located outside of China. He said tracking Great Wall’s rigs is “like finding a needle in a haystack” and referred to CNPC as the “global land drilling X-factor,” based on its potential to affect the balance of land rig supply and demand worldwide. Pickering noted that Great Wall may redeploy rigs from China to international rig markets as Chinese E&P companies purchase assets overseas.2

China is one of the few countries in the world for which Baker-Hughes Inc. does not track the monthly land rig count. BHI does track rigs working offshore China and in April and May 2005 recorded 16 rigs working offshore, a high not seen since June 1985.

In June, there were 18 rigs drilling off China. China Oilfield Services (COSL) had 10 jack ups and 3 semisubmersibles; Sheng Li Offshore had 3 jack ups drilling and another (Bohai XI) ready stacked; and Shanghai Offshore Drilling Co. had 1 jack up and 1 semisub drilling, according to Rigzone.

The lowest number of rigs working offshore China since January 1982 was zero, in September-October 1987. The average number in the 1980s was 8.3 offshore rigs; for 1990-94 it was 2.9 rigs; for 1995-99 it was 9.2 rigs. For January 2000 to May 2005, the average was 10.2 rigs working offshore China.

BHI has been tracking the split between oil and gas wells since January 1995. For the 10-year, 5-month period, on average, 7.9 rigs were drilling for oil and 1.8 rigs were drilling for gas offshore China. There was near parity in March-April 1995 and in April 2000, when 5 offshore rigs were drilling for oil and 4 others were drilling for gas. August 2000 is the only month is which more rigs were drilling for gas (6) than for oil (5).

Contract drillers

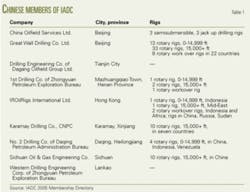

There are 60 drilling and completion companies listed by ChinaOilWeekly.com, and nine Chinese companies are listed as members of the International Association of Drilling Contractors in 2005 (Table 1).

The largest Chinese drilling contractor is Great Wall Drilling Co., a subsidiary of CNPC Services & Engineering Ltd., set up in 1993. Its earliest contracts included:3

• 1994-95: Peru; five production wells; $7.5 million.

• 1995: Uzbekistan; three production, two exploration wells; $3.5 million.

• 1995-97: Mongolia; five exploration wells; $10.4 million.

• 1998: Canada, Egypt; rigs leased.

GWDC provides directional, horizontal, under balanced, cluster, deep, and gas well drilling services around the world. As mentioned, Great Wall’s fleet contains at least 600 and maybe more than 700 rigs, including more than 100 operating outside of China.

At the IADC World Drilling Conference in Rome last month, Hermann Spörker, with OMV Exploration and Production GMBH, Vienna, presented a paper on drilling deep wells with a Chinese contractor.4

OMV chose Great Wall Drilling for a multi-well service contract onshore western Iran and in Tunisia (Rig 92). His comments focused on the predrill phase and drilling of the first Iran well. Spörker described the cultural differences and “heavily centralized and state-oriented behavior of the GWDC staff,” and discussed the economics of choosing a low day-rate bid for a multi-well program.

OMV’s Tunisia drilling took place in mid-2004. Ireland’s Petroceltic International PLC picked up the GW 92 rig for additional Tunisian drilling in November 2004.

On Jan. 17, 2005, OMV Iran Onshore Exploration GMBH announced a discovery in the Mehr Block in the Zagros fold belt of western Iran. GWDC drilled to 4,148 m TD in December and the well flowed 1,040 b/d of 22º gravity oil.

OMV and GWDC spudded the second well in OMV’s four-well Iranian drilling program in the Mehr Block on Mar. 7, 2005, and it was due to reach TD in June.5

Jianghan Drilling Engineering Co. (JHDC) is a subsidiary of the Jianghan Petroleum Administration Bureau (JHPA), a state-owned integrated enterprise, based in Qianjiang City, Hubei Province. JHDC has 26 drilling crews and five first class crews qualified by Sinopec, experienced in coring, directional drilling, horizontal well, slimhole drilling, and underbalanced drilling. JHDC rigs can drill to 7,000 m.

IROilRigs International Ltd. is a contract driller that has offered land drilling services since 1996 in Indonesia, China, Iran, Yemen, Uzbekistan, and Kazakhstan. The company has a strategic relationship with Beijing-based GCC Group Corp., a subsidiary of Houston-based GCC Group Corp.

GCC in China deals directly with rig and equipment manufacturers, drilling contractors and oil field service companies across China. GCC and IROilRigs work with provincial oil field companies and with Great Wall Drilling to supply rigs, equipment, and services.

Made in China

China produces many land rigs, a few offshore platform rigs, but almost no mobile offshore drilling units at this time. However, the Shekou Yiulian dockyard in Shenzhen Province has performed two successful offshore drilling rig upgrades for China Oilfield Services Ltd. Workers upgraded the Nan Hai No. 2 semisubmersible in early 2005 and the Nan Hai No. 5 semisub in 2002. This dockyard is relocating to the Mazhou Islands from Shekou, a project that began in December 2004 and will be complete in late 2006.6

Chinese drilling rig manufacturers are enjoying a surge of orders for new land rigs. The three largest manufacturers are Baoji Oilfield Machinery Co. Ltd. (BOMCO), Chuanyo Guanghan HongHua Co. Ltd. (HongHua), and Lanzhou petrochemical machinery plant.

BOMCO, based in Baoji, Shaanxi Province, is China’s largest manufacturer of drilling equipment and rigs, larger than all national competitors combined. Founded in 1937 as the Baoji Petroleum Machinery Manufacturing Plant (BPMMP), the company was reorganized in 2002 under CNPC.

The company offers mechanical and electric drive drilling rigs, derricks and substructures, wellhead equipment, mud pumps, pumping units, and solids control equipment. It has shipped products to 42 different countries, including the US, Canada, and Mexico, as well as countries in South America, Africa, Europe, Middle East, Asia, Australia, and New Zealand.

At Precision Drilling Corp.’s Yard 2 in Nisku, Alta., OGJ learned that PDC uses BOMCO mud pumps on its land rigs. Operations Manager Grant Hunter said the delivery time and price are substantially better than any supplier can provide in Canada or the US. He noted that the pumps are very similar to those from US-based Continental Emsco Co. (acquired by National Oilwell Inc. in 1999, now National Oilwell Varco Inc.). Older pumps carry metal plates with the old company acronym, BPMMP.

BOMCO built 55 drilling rigs in 2003-04 and as of May 2005, anticipated building 65 this year. A company representative told OGJ in May that BOMCO can build seven rigs at a time on the 100-acre site in Baoji. BOMCO was the first Chinese rig manufacturer to develop AC variable frequency drive rigs and to produce a top drive drilling system (1995).

The company offers 21 different rig designs, including AC-powered rigs, truck-mounted rigs and rigs for cluster drilling, slant hole drilling, and desert drilling, capable of drilling from 1,000 to 9,000 m.

BOMCO’s ZJ20/1350Z truck-mounted drilling rigs are also based on technology from Continental Emsco Model 65Band are the first portable, self-contained drilling rigs made in China.

Most of the BOMCO’s past construction was focused on hydraulic drive (Y) or DC drive (DZ) rigs, but new contracts call for variable frequency AC (DJ, DB) rigs, which are safer for gas drilling. The company’s newest design is an AC rig capable of drilling to 7,000 m, the ZJ70DB:

• ZJ-Zuan Ji, “drilling rig.”

• 70-7,000 m depth.

• DB-Dian Dong Bian Ping, variable frequency AC drive.

BOMCO offers 12 different drill rig substructures of five types: towing (T), self-erecting (S), vehicle-mounted (C), block-mounted (K), and terraced. It also offers 24 different derricks in four types: K-, T-, W-, and A- (cantilever, A-frame).

The company began supplying offshore equipment in the early 1980s. It built the ZJ45D drilling module for the Ganghai field’s No. 1 drilling platform, the first offshore dynamic derrick for the No. 3 exploration platform, and derricks, drawworks, and equipment for the Shengli offshore field (OGJ, July 11, 2005, p. 35).

HongHua

HongHua is the second-largest rig builder in China. Based in Guanghan City, Sichuan Province, the company has built 150 rigs since 1997 and is now able to construct 50 rigs/year. HongHua’s most powerful rig is a 2,600-hp design, but company representatives told OGJ that 1,500-2,000 hp models are more popular. Customers also prefer AC-drive rigs because they offer good control features and operate more safely, with fewer explosions, they said.

In 2004, HongHua also built two 135-tonne, 650 hp workover rigs for China National Offshore Oil Co. (CNOOC) and is starting to construct offshore platform rigs.

The company sold rigs to Great Wall Drilling and SPA, and HongHua rigs are drilling in fields throughout China, including Daqing, Shengli, Changqing, Sichuan, Xinjiang, and Zhongyuan.

HongHua rigs are operating in Indonesia; Thailand (4); Uzbekistan (10, sold in 2001); Kazahkstan (3); Turkmenistan (5); Pakistan (2); India (1); Venezuela (1); and the US.

GTS Drilling Services began working in Venezuela and then started contract drilling in Pakistan in 2002. GTS leased two HongHua rigs to Pakistan’s OGDC, both 2,000-hp mechanical rigs.

New Continental Equipment Co. Ltd., based in Houston, is HongHua’s first venture outside China, and the company plans to establish a second office in UAE later in 2005.

GTS is New Continental’s first US customer, and they are running a 1,300-hp variable frequency AC rig (model HH-1300VFD) in the Colorado Rockies.

Zhang Mi, president of HongHua, told OGJ that although steel prices have increased 50% in the last 2 years, he thinks they are near peak. As a rig manufacturer, he said the company needs to understand the advantages of other rigs built around the world in order to improve its own rigs. Zhang is particularly impressed with the H&P FlexRig design, calling it an “excellent rig,” especially with the integrated top drive. HongHua does not manufacture top drives, but the company’s masts are compatible with them.

Zhang said that when the demands of customers can be satisfied, “more rigs from China will be used around the world.”

Lanzhou, others

Lanzhou Petroleum & Chemical Machinery Equipment Engineering Group Co., in Lanzhou City, Gansu Province, builds land and offshore drilling rigs rated from 1,500 m to 9,000 m, as well as pumps and related oilfield equipment. BOMCO and HongHua both consider Lanzhou the third-largest rig manufacturer in China.

In March 2000, Turkmenistan’s state oil company Turkmenneft reported that Lanzhou petrochemical machinery plant was building two oil drilling rigs to be delivered in May-June 2000. The total cost of $22 million would be paid over 5 years.7

Another JHPA venture, SJ Petroleum Machinery Co. based in Jingzhou City, Hubei Province, designs several types of rigs for different terrain. It offers four different self-propelled truck-mounted rigs, capable of drilling to 1,000 m (ZJ10); 1,500 m (ZJ15); 2,000 m (ZJ20); and 3,000 m (ZJ30, with double engines). SJ developed the ZJ40LDB rig, a modular rig capable of drilling to 4,000 m.

SJ also developed the ZJ50DB AC-powered rig with USA Loadmaster Co., marketed as “Big Easy.” It has a three-part mast, lifted by hydraulics.

Rigs to Cuba, US

Cuba has been drilling with Chinese rigs for several years. Five additional rigs (four service, one drill rig) arrived in Cuba earlier this year, the Havana Journal reported, with three more expected.8

Two of the rigs will be able to drill to 7,000 m, and one rig will be capable of drilling to 5,000 m.

State-run Cubapetroleo (Cupet) is drilling exploratory wells with Canadian partners Sherritt International Corp. and Pebercan Inc. on the north coast. Pebercan’s National 110 rig was among three working on the north coast in 2004.9

China’s giant Sinopec Corp. has also entered a joint venture with Cupet to produce heavy oil in westernmost Pinar del Rio province; drilling will begin in 2006.8

Houston-based Ace Field Services is a US drilling contractor with a fleet of land rigs built in the US, Canada, and China. The company has agreements with Chinese drilling rig manufacturers to run and sell rigs in the US.

CBR Alliance

In 2002, the CACT Operators Group, an international partnership, contracted with the CBR Drilling Alliance for construction of two drilling platforms destined for the Huizhou field, in the South China Sea, 120 km southeast of Hong Kong (OGJ, July 11, 2005, p. 35).

The CBR Alliance was formed to provide turnkey contracts for new offshore drilling rigs in China. Within the alliance, RDS provides engineering design, procurement, and project management; Chiwan Sembawang Engineering Co. Ltd. (CSE) provides fabrication services and hookups; BOMCO supplies Chinese-manufactured drilling equipment (mud pumps, drawworks, rotary tables); and various strategic partners supply western-manufactured drilling equipment (top drives, switch gear, electrical generators).

CSE is a venture among SMOE Pte Ltd. (the oil and gas division of SembCorp Utilities Pte. Ltd.), China Offshore Oil Engineering Corp., and the Shenzhen Petroleum Supply Base Co. The CSE yard is in the Shenzhen Special Economic Zone.

RDS successfully completed the front-end engineering design (FEED) work for the Huizhou development, and then the alliance received an engineering, procurement, and construction (EPC) contract to supply the HZ 19-2 & HZ 19-3 drilling facilities, including two permanent derrick sets. The EPC contract started on Sept. 16, 2002.

RDS Operations Manager George Jackson told OGJ that the company provided engineering design and procurement services for the two derrick equipment sets and the drilling support module (Fig. 2). Each DES is rated at 1-million lb hook load and the DSM contains two 1,600-hp mud pumps. Power for drilling is supplied from the platform systems.

The DSM was designed as 16 discrete mini-modules, each lighter than 30 tonnes, which could be moved between the platforms using the regular platform cranes.

The rigs were fabricated in the CSE yard. BOMCO and Varco supplied the drilling equipment. The modules sailed away from the CSE yard on May 29, 2004, and installation on the platforms was completed July 10 (delay due to bad weather). Jackson said drilling in Huizhou Block 19, started on Oct. 7, 2004 (Fig. 2).

New Chunxiao rig

CNOOC China Ltd. contracted with Shenzhen-based CSE for construction of a new offshore platform rig for the East China Sea.

In June 2002, CNOOC awarded RDS a FEED contract to do the basic engineering for a removable modular drilling rig as a subcontractor to Technip-Coflexip Offshore, part of Technip Malaysia based in Kuala Lumpur. The drilling facilities consist of one DES and one DSM, which are to be shared by a number of platforms.

According to a company press release, RDS started detailed engineering work in December 2002. The specifications required a 2,000-hp rig with self-erecting mast, AC top drive, three 1,600-hp mud pumps, and a 10,000-psi BOP stack. The DES is rated at 1-million lb hook load was designed as two modules (645 tonnes and 466 tonnes).

The DSM contains three 1,600-hp mud pumps, and power for drilling is supplied by four 1,000-kw drilling generators. The DSM was also designed in two modules (630 tonnes and 624 tonnes) plus the bulk storage tanks. The six modules are installed or removed on each platform using a heavy-lift crane barge.

RDS’ Jackson told OGJ that the EPC contract started on Jan. 2, 2003, and the rig was constructed in the CSE yard in Shekou, southern China (Fig. 2). The derrick was ready in December 2004, but the deck, constructed elsewhere, was delayed. The modules sailed away from the CSE yard on Apr. 20, 2005, and installation on the platforms was completed by May 8. Drilling from the rig, named CNOOC Chunxiao, was to start on July 10, 2005.

Near the end of the project, in September 2004, RDS was acquired by the Abbott Group PLC, Aberdeen, and became a division of KCA Deutag. In a press release, Maurice White, chief executive of KCA Deutag noted that the acquisition would give the company access to “important Chinese market opportunities.”

China’s impact

China has reached out for foreign technology and investment to develop domestic projects and this will probably continue for some time. But Chinese drilling rig and oilfield equipment builders and drilling contractors have the potential to affect world rig markets if they can achieve consistently high quality and gain expertise.

In a roundtable discussion of China’s potential impact on the market for oilfield services, First Albany Capital analyst R. Thaddeus Vayda said, “China could rapidly evolve into a potent supplier of services and equipment to the rest of the world.”10

He also noted that western service companies benefit from the low cost of labor available in China: Grant Prideco Inc. has about 50% of the Chinese market for drill pipe, and National Oilwell Varco Inc. manufactures much of its new Ideal rig in China.

Another roundtable participant, Natexis Bleichroeder analyst Roger Read postulated that some of the jack ups being built speculatively (OGJ, July 4, 2005, p. 55) will be bought by Chinese oil companies. And there is also the possibility that China’s shipyards may eventually compete with Singapore yards in building mobile offshore drilling units. ✦

References

1. CNPC rig fleet; www.cnpcse.com.

2. Oil Service Topical Report, Pickering Energy Partnership Inc., June 7, 2005.

3. Xu, X., “China and the Middle East: Cross-investment in the Energy Sector,” Middle East Policy Council Journal, Vol. 7 (June 2000), No. 3.

4. Spörker, H., “Great Wall Drilling Company-Drilling Deep Wells with a Chinese Contractor,” IADC World Drilling Conference, Rome, June 9-10, 2005.

5. Petrossian, V., “OMV is marching on at Iran’s Mehr,” Upstream, May 20, 2005, p. 23.

6. News, May 15, 2005; www.yiulian.com.

7. “China to supply drilling units to Turkmenistan,” Mar. 31, 2000; www.gasandoil.com.

8. “Cuba oil production to increase with more Chinese equipment arriving,” Havana Journal, Mar. 23, 2005; www.havanajournal.com.

9. “Pebercan to increase oil exploration and development programs in Cuba,” Havana Journal, Oct. 28, 2004; www.havanajournal.com.

10. The Wall St. Transcript, Oil Services and Equipment issue, May 24, 2005, p. 62.