BP awaits approval to decommission NW Hutton

BP PLC expects approval in late 2005 from the UK government for decommissioning the Northwest Hutton platform. It submitted its decommission proposal to the government in January 2005 and plans to start offshore work in 2006 or possibly as late as 2009.

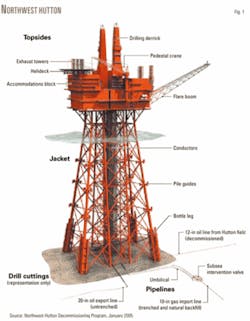

The platform is about 130 km northeast of the Shetland Islands in 140 m of water (Fig. 1). The platform is an integrated oil and gas drilling, production processing, and accommodation facility with a design typical of platforms designed in the late 1970s and installed in the early 1980s. Prior to UK government approval, BP will need to obtain an exception to the OSPAR 98/3 decision on its proposal to leave the jacket footings in place. The OSPAR convention regulates platform disposal activities in the European marine environment.

Production from Northwest Hutton field, in Block 211/27a of the UK North Sea sector, ceased in January 2003, with the wells abandoned and well conductors cut more than more than a year ago. The field’s cumulative oil was about 125 million bbl.

BP has not manned the platform since July 2004.

Interest owners of the platform are:

- Amoco (UK) Exploration Co., 25.8% (now BP).

- CIECO Exploration and Production (UK) Ltd, 25.8%.

- Enterprise Oil (UK) Ltd. 28.4%.

- Mobil North Sea Ltd., 20.0%.

Recommended program

The recommended program involves:

- Removing the topsides and steel jacket down to the top of the footings (the base of the jacket) for recycling onshore.

- Leaving the jacket footings in place, including the piles that fix the structure to the seabed. BP says that attempts to remove the footings would involve an unacceptable level of safety and technical risk.

- Leaving the drill-cuttings pile in place to allow the seabed to recover naturally. BP believes this solution ensures the least environmental impact.

- Trenching and burying the 20-in. oil pipeline and leaving the already trenched 10-in. gas pipeline in place.

BP based its proposed decommissioning proposal on a comparative assessment of all options, involving about 50 external studies. It used an independent review group of six environmental experts and engineers from the UK, Norway, and Germany to verify the assessment process and studies. Also it took into consideration the recommendations gathered during 2003 and 2004 from various stakeholders.

Topsides

The 22,000-tonne Northwest Hutton topsides includes individual modules and components (Fig. 2). The study recommends a reverse installation as the preferred removal option because offshore deconstruction would involve higher safety risk and single-lift technology is not yet available.

The work will require the separation of the topsides into 22 large components, weighing up to 2,200 tonnes. A crane barge will lift these components onto barges for transport ashore.

Jacket

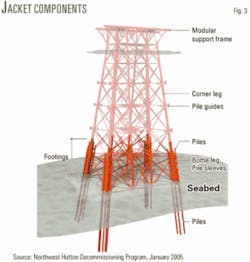

The Northwest Hutton jacket (Fig. 3) is the largest fixed steel structure that the industry has considered for decommissioning in the world, according to the study.

BP studied three removal options for the 155-m tall, eight-legged jacket: full removal, removal to top of footings, and partial removal of footings to the top of the drill cuttings pile (Fig. 4).

The study found that the option with the least safety risk was the removal of the jacket to the top of the footings. The jacket and piles weigh 17,500 tonnes. The study says that this option posed a potential problem for trawlers in that they could snag their nets, and therefore this small area would have to be excluded from fishing.

The footings extend to about 40 m above the seabed and consist of large 5.5-m diameter legs, bracings, and piles that account for about 50% of the jacket weight. The footings also have about 100 tonnes of cement grout around the base of the legs. The grout was needed to repair damage to the jacket incurred during its installation in 1981.

The study found that reverse installation and single lift would require removing the entire jacket by buoyancy methods or a purpose-built vessel but that such equipment currently does not exists.

The proposed method for jacket removal involves underwater cutting and use of large offshore cranes. This work will involve progressive cutting and removal of the jacket, starting at the surface and gradually working downwards. This removal process would require at least 20 lifts weighing up to 3,000 tonnes.

Drill cuttings

The drill-cuttings pile formed during development drilling on Northwest Hutton between 1982 and 1992. BP says that during this time cutting discharge onto the seabed after cleaning was the approved disposal method.

The proposal describes the pile as:

- Having a maximum 5.5-m depth in the centre and thinning to about 1.5 m around the jacket legs.

- Extending to 20-70 m beyond the jacket legs.

- Covering a 0.02 sq km surface area.

- Consisting of predominantly of rock, 48%, and seawater, 45%, with the remaining material being oil used in the drilling fluid together with small amounts of other chemicals used in the drilling operations.

- Having a total volume of about 30,000 cu m, including the seawater.

The program recommends to leave the drill-cutting pile in place to allow natural recovery. Some justifications cited for leaving the pile in place include:

- Possible contamination of the seabed from removal operations.

- Minimal environment impact of the stable pile.

- Recovery to shore would use valuable landfill capacity.

Pipelines

The program proposes to trench and bury the pipelines that include a 10-in. gas import pipeline from the Ninian Tee to Northwest Hutton and a 20-in. oil export pipeline from Northwest Hutton to the Cormorant ‘A’ tie-in.

Both steel pipelines have a coal-tar epoxy protective coating. The outer layers have a concrete coating for protecting the pipe and for providing weight. The pipelines have anodes for corrosion protection and at various places concrete mattresses for supporting and protecting areas such as pipeline crossings.

The 13 km, 10-in. gas pipeline originally exported gas to a gas transportation system, but in 1994 it was connected to the Ninian field gas export line so that Northwest Hutton could import gas for use as fuel.

During its installation, the gas pipeline was trenched to a depth of 0.45 m below the seabed. The study says the line is currently fully trenched along 100% of its length and buried along about 73% of its length.

The 20-in. oil pipeline, jointly owned with the Hutton field, exported oil and NGL from the Northwest Hutton field to Cormorant Alpha, which is about 13 km to the west. The study says the oil pipeline lies on the seabed and is not trenched.