Special Report: Study comparison reveals methane-emissions reduction opportunities in gas processing

Two studies have identified major sources of methane emissions in the natural gas processing industry.

This article identifies significant methane-emissions reduction opportunities, how these opportunities are evident from the two studies, and what these studies say about methane emissions from gas processing plants.

One study, published in 1996, was by the US Environmental Protection Agency and the Gas Research Institute (GRI, now the Gas Technology Institute, or GTI), Des Plaines, Ill.1 The second, published in 2002 by Clearstone Engineering Ltd., Calgary, and EPA,2 was based on methane emissions from four gas processing plants.

Concurrently, several economic methane-emission reduction options have been developed by gas-processing-plant operators and voluntarily reported to the US Natural Gas STAR Program, part of the EPA. Most of the Gas STAR technologies and practices also reduce operating costs and increase processing revenues.

The STAR program was implemented in the early 1990s as part of the US government’s climate change strategy. Gas STAR is a public-private partnership aimed at voluntary methane-emissions reductions.

Companies in gas processing in the US natural gas industry joined the Gas STAR program in 2000, following a study of best management practices (BMPs) for cost-effective methane emission reductions. This study involved the Gas Processors Association through an industry advisory committee.

The primary basis for the study was the landmark 1996 report sponsored by EPA and GRI based on data collected in the 1980s and early 1990s.

Based on the adopted BMPs, the gas processing companies that joined the Gas STAR Program reported saving more than 1 bcf of methane emissions in 2000.

Opportunities

US demand for natural gas continues to grow dramatically, in large part because methane is the cleanest burning fossil fuel. As US natural gas production has increased over the last decade, the number of US gas processing plants has decreased, with the capacity of the remaining plants increasing. Faced with growing demand, natural gas processors have an incentive to reduce methane emissions because natural gas emissions waste valuable product and revenue.

US natural gas processing plants emit about 37 bcf of methane annually.3 Consequently, identifying economic means of reducing methane emissions not only contributes to a cleaner environment but also improves the economics of the gas processing sector.

EPA and an industry advisory committee consisting of 10 gas processing companies and the GPA studied methane-emission reduction opportunities in gas processing in 2000. The purpose of this study was to identify suitable BMP candidates that would form the basis for this sector to reduce emissions through the Gas STAR Program.

The basis for methane emissions from gas processing was the 1996 EPA/GRI.3 The BMP analysis involved the following steps:

- Identifying sources of methane emissions for which there are lower emitting alternative technologies or operating-maintenance practices.

- Evaluating the amount of emission reductions that could technically be achieved by employing the lower emitting alternative.

- Evaluating the amount of emission reductions that are economically feasible with the alternative.

- Determining the present penetration of the lower emitting alternative in the gas processing sector.

The following seven BMP candidates were evaluated:

- Economic rod-packing replacement in reciprocating compressors.

- Replacing wet seals with dry seals in centrifugal compressors.

- Installing flash-tank separators on glycol dehydrators.

- Replacing gas pneumatic devices with instrument air.

- Directed inspection and maintenance (DI&M)4 of fugitive leaks in gas processing plants.

- Installing vapor-recovery units on NGL transfer from storage tanks to rail and truck transportation vehicles.

- Acid-gas-removal unit vent controls on the CO2 stream vented from amine regenerators.

In considering the definition of gas processing facilities, the industry advisory committee recommended that gas gathering and booster stations be included along with gas processing plants.

This was because gas processors either own or at a minimum operate the feed facilities to their processing plants and thereby have the opportunity to reduce emissions from those facilities. The industry advisory committee believed that there are more opportunities for cost-effective methane emission reductions in gathering and booster systems than in the processing plants themselves.

The study concluded that three emissions-reduction opportunities met the standards for BMP:

BMP 1: Replacement of high-bleed pneumatic devices (in gathering and booster stations).

BMP 2: Installation of flash-tank separators in glycol dehydrators (primarily in gathering and booster stations).

BMP 3: Directed inspection and maintenance at gas processing plants and booster stations.

Many gas processing companies have since joined the Gas STAR Program and reported undertaking such steps to reduce their methane emissions. As this article describes, however, more work remains.

In particular, reciprocating compressors’ seals appear to provide an opportunity for methane-emission reductions that has not been reported to the Gas STAR Program and one that can be economically reduced in processing plants and probably gathering and booster stations.

This article continues with a discussion of where the methane emissions were found in gas processing facilities and then discusses what is learned by comparison of the Clearstone study with the EPA/GRI study, relevant to opportunities for further reduction of methane emissions in gas processing.

Gas plant estimates

EPA’s National Methane Emissions Inventory,2 based on the GRI study, estimates that in 2000, gas processing plants emitted 37 bcf of methane, and Natural Gas STAR partners reported saving more than 1 bcf of methane from the processing sector.

Fugitive emissions from equipment leaks were the largest emissions category, contributing nearly 70% of total methane emissions, followed by venting and combustion emissions from normal operations at 25%, and the remainder from routine operating and maintenance activities such as equipment blowdowns.

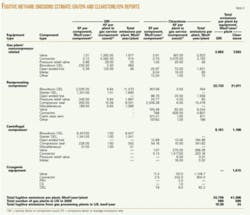

The GRI study used EPA Method 215 (sniffing components with an organic vapor analyzer) to screen for leaks and employed correlation equations to estimate methane emissions factors. The Clearstone study used a Hi-Flow Sampler that gives a direct reading of mass emissions to quantify emission factors. Table 1 shows average per-plant methane emissions from gas processing from the GRI and Clearstone studies.

This section provides an overview of these emissions estimates from the two studies.

The Clearstone study defined fugitive emissions screened above 10,000 ppm (vol) as “leakers” and those below that threshold as “nonleakers.” The study screened 101,193 components across four processing plants; about 2,630 (2.6%) of the components were found to be leaking. The total hydrocarbon emissions rate from leakers was measured with the Hi-Flow Sampler. A default-zero methane emission factor from the EPA correlation equations5 was used for nonleakers.

The GRI study, which was published 9 years earlier than Clearstone’s, used data from surveys of 7 processing plants combined with results of three prior studies by EPA and the American Petroleum Institute that covered 14 gas plants. The EPA/GRI/API studies screened 87,923 components, finding 5,872 (6.68%) were leaking more than 10,000 ppm (vol). GRI used EPA correlation equations to estimate fugitive methane emissions from these 21 processing plants.

The EPA/GRI/API studies also quantified individual vented and combusted emissions from compressors, processes, and pneumatic devices. Clearstone made measurements or engineering calculations of numerous vent stacks in the four-plant studies but found that most of these vents were manifolded to numerous emission sources, making it impractical to relate emissions reliably to any single source. Therefore, Clearstone grouped all vented and flared emissions into one category.

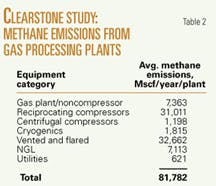

Table 2 summarizes estimated methane emissions from components associated with the different equipment types in a gas processing plant based on the Clearstone study data. The “Gas Plant/Noncompressor” equipment category includes equipment in the natural gas section of the plant excluding the compressors, i.e., dehydration units, nitrogen-rejection unit, mercury-removal unit, gas sweetening, and the demethanizer.

The “NGL” category represents the section of the plant after the demethanizer. This includes the de-ethanizer, depropanizer, debutanizers, stabilizer, propane refrigeration, and LPG and NGL storage tanks and pumps. The compressor-related equipment is sub-categorized by type of compressor: reciprocating or centrifugal. The “Cryogenics” section includes the refrigeration unit that uses turboexpanders.

The “Vented and Flared” category covers vented emissions from components that are manifolded either directly into vent stacks or to the plant flare header. The “Utilities” includes the cogeneration equipment, the Claus sulfur plant, heat pumps, and other utilities. The noncompressor related equipment, reciprocating and centrifugal compressor related components, cryogenic equipment, and vents and flares are considered to have methane as the primary hydrocarbon fraction and contribute about 90% of the total methane emissions from gas plants.

Comparison of results

The level of detail in the Clearstone study provides an opportunity to organize the data for direct comparison with the GRI study.

Table 3 shows the main fugitive-emission source categories from Table 2, broken down to sub-categories of emissions’ source types. The categories of “NGL” and “Utilities” have been left out of the comparison because they are minor sources of methane emissions (Note: A single large emission from an NGL-water separator tank thief hatch dominates the value for methane emissions from NGL in Table 2.)

The average fugitive emissions per plant based on the Clearstone study are 41 MMcf/year/plant, which is 22% higher than the GRI estimate. The Clearstone study has identified cryogenic equipment as emission sources that were not identified in the GRI study. Table 3 shows the comparison between the fugitive-emissions estimates of the two studies by equipment and component categories, and the following section gives an overview of the results.

- Noncompressor-related emissions. For emissions from noncompressor related sources, the estimates from Clearstone are about 155% higher than the GRI study values. Although the activity factors in the Clearstone study are slightly lower, the emissions’ factors are much higher (between 20% and 480% higher) resulting in larger emissions.

The Clearstone data do not differentiate between regular open-ended lines (OEL) and blowdown OEL (BOEL); hence, there are no separate estimates for the two. Valves and connectors are the two largest contributors of emissions in this equipment category due to their large numbers.

OELs, however, have a much higher emission factor and are fewer in number than connectors. OELs form only 1.7% of total components but contribute nearly 21% of all emissions in this equipment category. Thus, OELs may be a prime candidate to focus the DI&M practice for emissions reduction. Clearstone has also identified “Meters” as a small methane emissions source, a source not identified in the GRI study.

- Reciprocating compressors. The dominant type of compressor used in gas processing is reciprocating: The GRI report estimates that reciprocating compressors formed 85% of the total compressor population in the gas processing industry.

Components associated with reciprocating compressors are subject to high thermal and vibrational stresses that make them prone to leaks and are therefore among the largest source of emissions in the gas plant. The Clearstone study’s estimate for emissions from this category is about 35% higher than the GRI study.

There are significant differences, however, in estimates at the component level within this category. According to GRI, BOELs are the largest emissions source, contributing about 50% of all emissions from reciprocating compressors. The Clearstone study has only two data points related to emissions from blowdown and their average is small. The Clearstone data, however, estimate much higher emissions from compressor seals than does the GRI study.

Clearstone has also identified valves and connectors as major sources of emissions that the GRI study does not explicitly list. Total emissions from GRI’s miscellaneous category are far too small to include valves and connectors as identified by Clearstone. Thus, according to Clearstone, compressor seals, valves, and connectors are the top three emission sources in that order and together comprise 90% of the emissions from reciprocating compressors.

- Centrifugal compressors. These studies present centrifugal compressors as a smaller source of emissions than reciprocating compressors. GRI shows an individual centrifugal compressor emitting more than an individual reciprocating compressor. Due to the low numbers of centrifugal compressors used in gas processing, however, they do not contribute as much as reciprocating compressors to the total emission volume.

The GRI emissions’ estimate is heavily weighted by one particular component: the BOEL that is estimated to contribute 6,447 Mscf/year or nearly 79% of all emissions from centrifugal compressors, plus another 15% that comes from starter OELs. The Clearstone study does not have any data points clearly relating to blowdown or starter OELs, and emissions from other components are much smaller, resulting in much lower total emissions from centrifugal compressors.

The Clearstone data show compressor seals as the largest emissions source. The study does not identify, however, the type of seal-wet or dry-and it is difficult to discern whether the estimate for compressor seals or other OEL accounts for vents from wet seal oil degassing. The Clearstone study also identifies a few sources of emissions, valves, connectors, pressure relief valves, and meters, that are not shown explicitly in the GRI estimates.

According to the 1992 GRI survey, centrifugal compressors accounted for 15% of all compressors in gas plants. Anecdotal data, however, suggest that the proportion of centrifugal compressors has been increasing steadily since the GRI data were collected.

- Cryogenic equipment. Containing only turboexpanders and the equipment associated with them, the cryogenic equipment category was not identified in the GRI study and so is a “new” source of methane emissions. Total emissions from turboexpanders are small and contribute less than 3% of total methane emissions in a gas plant. The individual components contributing to emissions are valves, connectors, pressure-relief valves, compressor seals, and open ended lines.

Results

This section examines the evidence in the two studies that supports emission-reduction opportunities described earlier.

While the GRI study concluded that fugitive emissions contributed 70% of all methane emissions at gas plants, the Clearstone study estimated this value to be 56%. Thus, both studies point to fugitive emissions representing a significant opportunity to reduce methane loss, and the Clearstone study further reinforces the conclusion that DI&M4 is an important practice for methane-emissions reductions.

Clearstone’s fugitive emissions in noncompressor related facilities are more than double those in the GRI study. This is not due to a larger number of component count but rather to higher emission factors primarily in valves, connects, and OELs.

In the compressor-related sections, there is a potential discrepancy between the two studies in emissions estimates from compressor blowdown and start-up vents. None of the Clearstone emissions factors suggests that large volumes of gas are vented during these routine venting operations, which suggests that the manifolded vents evaluated by Clearstone, included in the “vented and flared” category, likely included some significant contributions from compressor sources.

While GRI’s total plant emissions from blowdown and start-up vents are 30 times higher than Clearstone’s, even this magnitude is probably not from actual venting but rather from leaking shut-off valves.

Clearstone’s blowdown and start-up vent lines may also be included in their general category of “open ended lines” along with the numerous small-diameter vent and drain connections commonly regarded as OELs (as opposed to elevated vent stacks). GRI apparently grouped such small-diameter OELs under the category of “miscellaneous/other” fugitive sources, along with valves and connectors.

In any event, DI&M at gas processing plants and booster stations4 is an even more important practice for fugitive methane-emissions control in compressor-related areas. More and more operators are also taking advantage of a new technology, optical leak imaging, to make leak detection much more cost effective. This technology allows the operator quickly to scan a large number of components in a process area and see leaks normally invisible to the human eye through an infrared camera viewfinder.

The much larger emissions from blowdown and start-up vents in GRI are offset in the Clearstone study by much larger reciprocating-compressor-seal emissions. This suggests that economic rod-packing replacement in reciprocating compressors is an important practice in addition to those identified in the EPA Gas STAR BMP study.

The GRI emission factor in processing plants was found to be about equivalent to rod-packing emissions in an economically maintained seal system. Therefore, it was concluded in the processing sector BMP study that there is little opportunity for technical or economic emission reductions with this practice. Clearstone’s emission factor, however, of 250 scf/hr, five times higher than GRI, would suggest that the reciprocating compressor seals in the four plants tested might not be maintained to an economic standard.

The Gas STAR Lessons Learned study on Reducing Methane Emissions from Compressor Rod Packing Systems6 shows that seals can be economically replaced when emissions increase by 55 scf/hr, assuming a $3/Mscf natural gas price. If the Clearstone study plants represent the worst 20% of processing plants in methane emissions, the sector may be able economically to save about 1.5 bcf/year of methane emissions by practicing economic rod-packing replacement.

One other significant difference between Clearstone and GRI studies is the cryogenic equipment category. Whether the GRI plants did not include cryogenic equipment or that equipment was simply included in normal plant fugitives is unknown. All four of the Clearstone processing plants had cryogenic operations.

Outside this one source, the fact that Clearstone’s and GRI’s total fugitive emissions are nearly in parity appears to be coincidental rather than systematic. DI&M is clearly an excellent BMP for gas processing plants, as determined by the EPA BMP study for the gas processing sector and approved by the industry advisory committee.

Moreover, it appears that economic rod-packing replacement is a valuable practice in addition to the gas processing sector BMPs and could be even more valuable applied to gathering and booster station compressors where virtually all compressors are reciprocating.

Major findings

Overall, the Clearstone study performed a decade later than GRI’s reinforces the GRI/EPA study in suggesting that there are several opportunities for economic methane-emissions reduction in gas processing plants. Although the individual releases of methane may appear to be minimal, they are often continuous in nature and cumulatively very significant.

Following are some specific conclusions and recommendations derived from these two processing plant studies:

- That the two studies arrive at similar gas-processing-plant fugitive emissions (33,756 Mscf/year in GRI vs. 41,386 Mscf/year in Clearstone), albeit distributed differently, reinforces the notion that there are significant methane-emission reduction opportunities.

The four gas processing plants in Clearstone appear to have processing equipment (cryogenic) not identified in GRI. Much higher emissions in some sections of the processing plants in one study (e.g., noncompressor-related fugitives in Clearstone more than double those in GRI) are offset by higher emissions in other sections from the second study (e.g., OEL vents in GRI more than five times those in Clearstone).

- Both the GRI and Clearstone studies provide evidence to support continued or expanded efforts to control fugitive leaks through a DI&M program. In particular, GRI shows that compressor starter and blowdown open-ended lines are a significant source of leaks. This source is typically a roof vent that is difficult to measure and therefore cost-effective methane emissions reduction repairs are not identified.

Blowdown vent emission mitigation may be as simple as closing the shutoff valve tighter. Clearstone found valve and connector emission factors three to five times higher than GRI, and, although individually small, the large number and continuous nature of these leaks add up to large savings. Valve-stem-packing leak mitigation may be as simple as tightening the packing gland.

- The Clearstone study found reciprocating compressors’ seals leaking five times the rates in the GRI study. This rate would justify the practice of cost-effective rod-packing replacement and could potentially save another 1 bcf/year of methane emissions.

- The Clearstone study emissions measurement by High-Flow Sampler affords much superior measurement than the EPA Method 21 correlation equations used in GRI.

While gas-processing plant operators have already reduced methane emissions in their operations, GRI and Clearstone study provide ample evidence that reciprocating compressors’ seals and fugitive leaks in other areas present opportunities for significantly more methane-emission reductions and therefore additional revenue generation for gas processing plants.

References

- US EPA and GRI. Methane Emissions from Natural Gas Industry Vol. 8: Equipment Leaks Available through NTIA. Springfield, Va. 1996. Publication No. EPA-600/R- 96-080h.

- US EPA and Clearstone Engineering Ltd. Identification and Evaluation of Opportunities to Reduce Methane Losses at Four Gas Processing Plants. 2002. GRI-02/0119.

- US EPA. Inventory of US Greenhouse Gas Emissions and Sinks: 1990-2002. Apr. 15, 2004. EPA 430-R-04-003.

- US EPA. October 2003. Lessons Learned From Natural Gas STAR Partners: Directed Inspection and Maintenance at Gas Processing Plants and Booster Stations. EPA430-B-03-018 (www.epa.gov/gasstar).

- US Environmental Protection Agency. Protocol for Equipment leak Emission Estimation, EPA-453/R-93-026, NTIS PB93-229219, Emission Standards Division, June 1993.

- US EPA. July 2003. Lessons Learned From Natural Gas STAR Partners: Reducing Methane Emissions from Compressor Rod Packing Systems. EPA430-B-03-011 (www.epa.gov/gasstar).

Based on a presentation to the 84th Annual GPA Convention, San Antonio, Mar. 13-16, 2005

The authors

Roger Fernandez ([email protected]) is a program manager with the US EPA Natural Gas STAR Program, joining in September 2002. Previously, he worked at the Japanese Ministry of Environment and the Japanese Ministry of Economy, Trade and Industry in Tokyo, Japan from 2000-02. From 1996 to 2000, he worked with the coal industry to harness methane from active coal mines on the US EPA Coalbed Methane Outreach Program. And 1994-96, he reviewed air regulations in the US EPA Office of Policy, Planning and Evaluation. Fernandez served in the US Peace Corps in Mongolia 1992-94 and graduated from Michigan State University in 1992.

Don Robinson (drobinson @icfconsulting.com) is a senior principal at ICF Consulting. He worked in the US and international petroleum industry for 27 years, upstream and downstream, with Chevron Corp., Aramco, and Mobil Oil Corp. Robinson joined ICF in 1997 and has contributed to the US EPA Natural Gas STAR program for 8 years. In the private sector, he worked with BP PLC, GRI Canada, and Petrobras on their greenhouse gas-emissions auditing programs and development of ICF’s proprietary Greenhouse Gas Emissions Management System. Robinson received BS and MS degrees in chemical engineering from the University of Southern California.

Vineet Aggarwal (vaggar- [email protected]) is a senior associate at ICF Consulting and specializes in greenhouse gas emissions and analysis of oil and gas markets. Formerly he was a product engineer with Grindwell Norton Ltd. in India. He received an MS in industrial engineering and operations research from the Pennsylvania State University and a BE in production engineering from V.J.T.I, University of Mumbai. Aggarwal is a member of the Institute for Operations Research and the Management Sciences and the United States Association for Energy Economics.