Wet gas, multiphase meters enable more deepwater production

Many deepwater developments will require operators to measure multiphase flows, especially in cases where a host or hub platform processes commingled production from satellite fields.

Multiphase metering, thus becomes an enabling technology for projects not only for Subsea installations but also for augmenting well testing capabilities at the hubs, as was demonstrated on the Augur and Canyon Express projects in the Gulf of Mexico.1-3

Currently the industry does not have commonly accepted procedures and testing protocols for qualifying a multiphase meter. This necessitates that the working-interest owners, regulatory bodies, and other parties concerned with the commingled streams review multiphase measurement technology and agree on how this technology may affect production allocation.

Resolving this issue requires time and a sufficient lead time.4 Because multiphase metering technology is relatively new, a project may not have enough performance data to use as an analog for the application under consideration.

The operator may have to qualify the multiphase metering system to establish that the selected system can deliver the performance and measurement accuracy for the intended applications.

The two major qualification processes, field testing and loop testing, have advantages and disadvantages.

Multiphase meters also can change the well testing practices, such as the number and frequency of well tests, because the meters enable almost continuous well monitoring. This may affect the operational philosophy currently controlled by the availability and capacity limitations of a production separator on the hub platform.

In addition, availability of online measurement data can enhance the role of measurements in reservoir management.5

Deepwater trends

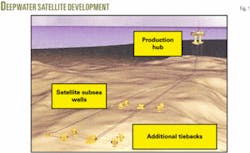

Increasingly Gulf of Mexico deepwater developments have commingled production from satellite reservoirs tied back to a host production facility that processes the produced fluid and exports the processed fluids to a pipeline network.

Several hubs such as Diana-Hoover, Mars, and Ram Powell are operating and the industry continues to add new hubs.6 Because the ownership in the satellite reservoirs may differ, accurate measurement of the produced stream at each location is important for commercial reasons and reservoir management.

Many existing hubs use gravity-based test separators (GBTS) for conventional well testing and production measurements. As the number of tiebacks and the distance from the hub increases, however, the use GBTS at the hub for production measurement becomes less effective.

The weight and space constraints on these host facilities may restrict installation of additional test separators, limiting the frequency of wells tests. A low well-test frequency can lower the quality of the test data used for reservoir management and field production allocation.5 7

In these cases, multiphase meters that measure the full well stream could become necessary.

Multiphase metering

Multiphase metering in its broadest sense refers to both wet-gas metering as well as the measurement of oil, water, and gas streams.8 Whether one is conducting a wet gas or multiphase measurement typically depends on whether oil or gas is the primary fluid produced and on the type of equipment in use.

Multiphase meters measure oil, gas, and water flow rates in a well stream without completely separating these components into individual phases.

Reference 8 provides an overview of multiphase and wet-gas metering techniques.

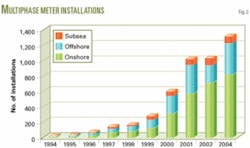

Currently, the industry has more than 1,000 multiphase metering installed worldwide (Fig. 2).9

Less than 10% of these installations are Subsea and only a handful are in deep water. A reasonable amount of data, however, is now available to assess system performance and measurement accuracy from flow-loop tests, field tests, and actual onshore and offshore operations.3 8 But the wet-gas metering systems have limited available service records and operational data, especially in Subsea applications.8

Operators and project planners can use the available data to scope a multiphase meter installation. But this technology lacks comprehensive operational and measurement history for many applications. This means that conclusive performance data may be unavailable for the type of application that is under consideration.

The operator will have to qualify a system to establish that the selected metering system can deliver the performance and measurement accuracy for the intended applications.

Well testing, allocation

Traditional well testing, production measurements, and allocation methods are undergoing changes as deepwater production scenarios adopt measurement techniques that address commingled well streams.10 Understanding these changes during the planning stages of deepwater projects is important.

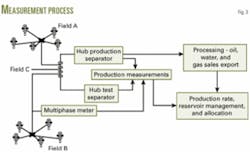

Traditionally for commingled production, the industry has used forced or proportional allocation to determine the flow stream share for a given field or reservoir. This allocation for commingled fields A, B, and C (Fig. 3) assumes that Equations 1 and 2 (see equation box) determine the final share of production for Field A.

The allocation factor typically may vary from 0.85 to 0.95.5 The factor represents the total imbalance of flows going into and out of the production measurement system.

Proportional allocation assumes that the production-measurement systems at A, B, and C have the same accuracy or uncertainty. Current allocation agreements in the industry contain a variety of procedures.

API Recommended Practice RP-85 provides an uncertainty-based allocation to distribute the total imbalance (AF) to various streams αi (Equation 3).11

The application of uncertainty-based allocation (UBA) rather than proportional allocation will affect production measurements. Accounting processes and systems may also have to change to accommodate the UBA procedure.

Current experience with multiphase measurements and commingled streams at Canyon Express and Augur have indicated that the following issues must also be addressed and incorporated into operating practices:1-3 10

• Monitoring of the performance of multiphase measurement systems on an accelerated basis against traditional parameters such as the data from processed streams (single phase) at the export points. This would provide a quality-control check to detect changes in system performance. Typically this process is used with conventional production measurements monthly.

• Designing the system and measurement practices to identify any bias in each stream and to take into account several commingled streams and various multiphase meters involved in a production scheme (Fig. 1). Measurements of an individual stream when other streams are shut down for periodic maintenance or scheduled production stops would be one way to accomplish this.

• Taking into account that multiphase measurements generally are conducted at higher pressures and temperatures than conventional (GBTS) process. These measurements, furthermore, could involve mixed streams with different properties. This means that the pressure-volume-temperature (PVT) data and issues such as shrinkage, entrained gas, etc. would affect the allocation process more than conventional measurement processes.

Well testing practices, such as the number and frequency of well tests, will change because the multiphase meters can almost continuously monitor wells. This may affect the operational philosophy currently dictated by the availability and capacity limitations of production separators on the hub platform.

In addition, availability of online measurement data from the multiphase meters could alter the measurement role in reservoir management.5

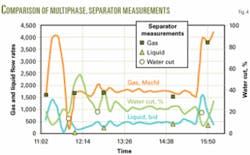

Fig. 4 compares measurement data obtained with a multiphase meter with data from a conventional test separator. The multiphase meter can detect many transient variations in flow rates that may go undetected with conventional gravity-based test separators (Fig. 4).

Reservoir management and well-performance diagnostics could take advantage of data-mining techniques to further use the online multiphase measurements.

Qualifying multiphase meters

Multiphase and wet-gas meters employ a variety of techniques and devices to measure the oil, gas, and water components in a flow stream.8 12 Each multiphase meter reacts differently to changes in process conditions, such as flow rates (flow regimes), fluid properties (oil density, water salinity, etc.), presence of wax or scale, sand content, and gas volume fraction of the flow.

The effect of process conditions and fluid properties on the measurement performance and accuracy can vary from tolerable to very significant. The user must, therefore, qualify the meter performance for a specific application.

The industry currently has no commonly accepted procedure or standards to guide users and regulators in the application and qualification of the multiphase meters.8 Several organizations and regulatory bodies, however, have developed or are in the process of developing guidelines that cover the application and qualification of multiphase and wet-gas meters.8 13-15

These references and publications address various aspects of the multiphase and wet-gas metering applications.

Up to now the industry has used either field testing or loop testing to qualify the performance of multiphase meters for most installations shown in Fig. 2.8

Field tests qualify meter performance under operating conditions either as a precondition to the purchase or Subsequent to the field installation. It consists of comparing the performance of the multiphase meter against a conventional gravity-based test separator in a field where the composition and flow rates of the produced fluids closely resemble the composition and flow rates of wells in the intended application. Typically the test rigs up one or more multiphase meters in series (Fig. 5) and Subjects them to the production stream.16

The test compares the readings from the multiphase meters with the output of a test separator measuring the same production stream. Differences in these readings determine the accuracy of the multiphase meter.

This approach is time consuming and fairly expensive, and the test must pay strict attention to the calibration and operation of the test separator that provides the reference values.8 16 Because the data obtained with a field test are with fluids and flow conditions similar to those anticipated in the final application, many in the industry consider the test as the most acceptable procedure.

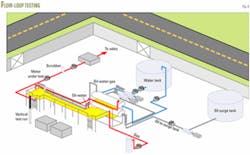

A second approach to performance qualification consists of testing multiphase meters in a flow loop (Fig. 6). In this approach, the test measures a single-phase fluid, for example oil, water, and gas, before the fluids mix and form a multiphase stream. This multiphase stream then flows through the multiphase meter. The difference in the single phase and multiphase readings determines the accuracy of the multiphase meter.

Several facilities in and outside the US can perform loop tests.8 These facilities use a variety of test fluids that can include kerosine, water, and air to simulate produced oil, water, and natural gas.

To establish the multiphase meter accuracy, the loop testing can expose the multiphase meter to a large variety of fluid mixtures and flow conditions under controlled conditions. Flow loop qualification may cost less and take less time than field tests, but in most cases loop tests cannot duplicate flow conditions and fluid properties in a real application. One has to extrapolate the loop data to obtain meter performance under anticipated field conditions.

Field testing is impractical for most Subsea and deepwater developments. Duplicating flow and fluid properties under operating conditions in a flow loop also is difficult if the actual application involves high pressures and temperatures. These conditions usually will require loop testing for determining the accuracy of the meters, and this will require one to extrapolate the loop data to actual conditions. This means that the facility operations must incorporate accelerated performance testing and periodic measurement quality control checks.17

Qualifying a multiphase metering system for an application requires considerable efforts, time, and head start. The efforts and time must be incorporated in the project planning stages to achieve successful application of this technology. ✦

References

1. Wallace, B.K., et al, “Canyon Express Subsea Multiphase Flow Metering System: Principles and Experience,” Paper No. OTC 15098, OTC, Houston, May 5-8, 2003.

2. Williamson, K., “Multiphase Metering of Deepwater Flowlines- The Auger Experience,” Third Annual Multiphase Users Roundtable, Houston, May 7, 2003.

3. Sharp R., “MPFM Pulling It All Together-How MPFM works for Augur TLP,” TAMU Multiphase Metering Users Roundtable, Houston, May 5, 2004.

4. Bertolin, L., Mehdizadeh, P., and Stobie, G., “Petrozuata- An Application of Multiphase Metering Technology,” Paper No. SPE 89870, SPE ATCE, Houston, Sept. 27-29, 2004.

5. Theuvey, B.C., and Mehdizadeh, P., “Multiphase Flowmeters for Well and Fiscal Applications,” Paper No. SPE 76766, SPE Western Regional/AAPG Pacific Section Joint Meeting, Anchorage, Alas., May 20-22, 2002.

6. Deepwater Gulf of Mexico 2002- America’s Expanding Frontier, OCS Report MMS 2002-021, April 2002.

7. Mehdizadeh, P., and Perry, D., “The Role of Well Testing in Recognizing Deferred Production Revenue,” ASME-ETCE, Houston, Feb. 4-6, 2002.

8. White Paper-State of Art, Multiphase Flow Metering, API Committee on Petroleum Measurements, TP 2566, August 2004.

9. Mehdizadeh P., “Status of MP and WG Metering,” TAMU Multiphase Measurement Users Roundtable, Houston, May 4, 2005.

10. Webb, R.A., “Allocation Methods for Commingled Production Using Multiphase Measurements,” TAMU Multiphase Metering Users Roundtable, Houston, May 5, 2004.

11. Use of Subsea Wet-Gas Flowmeters in Allocation Measurement System, API Recommended Practice RP-85, Aug. 28, 2002.

12. Mehdizadeh, P., Marrelli, J., and Ting, V.C., “Wet Gas Metering: Trends in Application and Technical Development,” Paper No. SPE 77351, SPE ATCE, San Antonio, Sept. 29-Oct. 2, 2002.

13. “Guideline Notes For Petroleum Measurements Under The Petroleum (Production) Regulations,” Issue 7, UK Department of Trade and Industry, Oil and Gas Division, December 2003.

14. Primeaux, Eric, “Allocation Procedures Utilizing Wet Gas and Multiphase Meters,” Third Annual Multiphase Users Roundtable, Houston, May 7, 2003.

15. Williamson, J.M., and Mehdizadeh, P., “Alaska Regulatory Guidelines For Qualification of Multiphase Metering Systems for Well Testing,” Paper No. SPE 94279, SPE Western Regional Meeting, Irvine, Calif., Mar. 30-Apr. 1, 2005.

16. Hasebe, B., Hall, A., Smith, B., Brady, J., and Mehdizadeh, P., “Field Qualification of Four Multiphase Flowmeters on North Slope, Alaska,” Paper No. SPE 90037, SPE ATCE, Houston, Sept. 27-29, 2004.

17. Cooly, C., “Experience with Wet Gas Flowmeters on Canyon Express,” TAMU Multiphase Metering Users Roundtable, Houston, May 5, 2004.

The author

Parviz Mehdizadeh ([email protected]) is a consultant with Production Technology Inc. He previously worked for Conoco Inc. Mehdizadeh holds BS and MS degrees in physics and a PhD in chemical engineering and materials science from the University of Oklahoma. He is a member of SPE well operations committee and is currently working with the API committee on petroleum measurements.

Based on a presentation to the Deepwater Offshore Technology Conference, New Orleans, Nov. 30-Dec. 2, 2004.