In situ seismic stimulation shows promise for revitalizing mature fields

Field tests in the Elk Hills sandstone in Kern County, Calif., showed that seismic stimulation with a downhole impact tool could increase production.

In the test area with two downhole tools installed, production increased from about 1,556 b/d in December 2003 to 2,212 b/d in December 2004. Since then, Occidental Oil & Gas Corp. has installed four more of the Applied Seismic Research Corp. (ASR) Hydro-Impact tools in its Elk Hills field.

For several decades interest in elastic-wave stimulation focused primarily on acoustic and to a lesser degree on surface vibroseis stimulation. The third more recent technology is in situ seismic stimulation, which uses the downhole impact tools.1-4

Regrettably, the three types of stimulation often are thought of as one group with similar objectives and results, which is not the case.

Acoustic stimulation

Acoustic stimulation tools address near-well problems such as skin effect using elastic waves with frequencies ranging from 100 hz to ultrasound.5-15 The most prevalent of these tools are based on piezoelectric,12 magnostrictor,13 15 and Coanda-effect5 8 generators and to a lesser extent on exotic11 14 generators.

Literature reports successful cases of successful acoustic stimulation,6 16 nevertheless the authors believe that this type of stimulation suffers from severe limitations because:

• With few exceptions, the low-power of the tools, ranging from 10-100 kw, limits cleaning effectiveness.5 7 9

• The technology does not address the need to measure the target Eigen frequency, for example the intrinsic frequency of each saturated porous medium.5 6 This means that an optimal stimulation under resonance of the porous medium is unlikely.

• The stimulation in some cases can damage the production zone.

• These methods do not address the need for economic, continuous stimulation of injection wells for periods of 6 months or longer.

Surface vibroseis stimulation

Seismic waves generated by earthquakes can increase oil production in some wells by as much as 45%.6 Also theoretical and experimental research shows that high energy, low-frequency (seismic) wave fields increase oil recovery and production.6 17

In the 1980s, efforts to duplicate earthquake effects employed massive 20-40 ton vibrators installed at the surface above the targeted oil zone.6 17 18 Field tests showed these vibrators created high energy, low-frequency elastic-wave fields that could enhance the mobility of the in situ oil, thereby increasing oil recovery and production rates. The disadvantages of this technology, however, limit its commercial use because:

• The source is at the surface and the target is typically a few thousand feet below; hence, multiple reflections of the elastic waves from the formation strata cause the attenuation of the elastic waves as they travel from surface to the productive reservoir.

• Vibroseis equipment requires enormous amounts of energy to operate.

• The equipment tends to overheat after short periods of use and develops mechanical problems with continued use. Thus, continuous long-term 2-4 operations are neither possible nor plausible.

In situ seismic stimulation

Field cases and lab work performed at the Los Alamos National Laboratories show the benefits of in situ seismic stimulation.3

In the field cases, the results from using a single second-generation tool compared favorably to a multimillion-dollar hydraulic fracturing program. Whereas the fracturing caused improvements in seven wells, a single ASR impact tool caused improvements in oil production and oil cut in 60 wells.3

The magnitude of the production increase and water cut decrease from the operation of a single tool compared favorably to the results from a series of earthquakes ranging from 5.5 to 7 on the Richter scale.3 The only difference was the duration because an in situ seismic tool continues to stimulate production for as long as the tool is in operation.

The Los Alamos Lab studies proved that only small pressure disturbances of less than 0.01 psi could increase the permeability of the saturated porous medium. Clearly the shockwaves carrying pressures of 3,000-3,500 psi at the wave front are sufficient to dislodge oil and hence stimulate an oil-bearing reservoir.

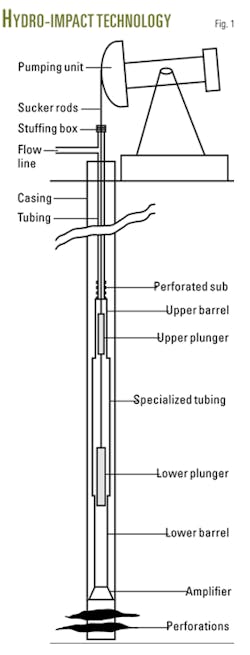

Fig. 1 shows the impact tool and associated equipment required for generating shock waves in a borehole. The impact tool has two slightly modified standard tubing pumps consisting of two barrels that contain two plungers connected with sucker rods.

Several joints of specialized tubing connect the two barrels.

Simultaneous lifting of the plungers compresses liquid trapped inside the specialized tubing and, at the top of stroke of the pumping unit, the plunger exits the top of barrel and generates a powerful hydrodynamic shock wave within less than 50 ms.

The shock wave moves through the perforations and propagates through the formation at speeds as great as 1.5 miles/sec. The shockwave has a power ranging from 2 to 10 Mw and a pressure at the wave front in excess of 3,000 psi. Because the wave passes through the wellbore casing and cement in a matter of microseconds, it does not damage the completion. The time is insufficient to damage the completion or to fracture the rock.

The shockwave transforms into an elastic wave as it travels distances of up to 1 mile in all directions.

An operator can install the impact tool inside the casing of an injection, production, or abandoned well.

In an injection well, injected water travels down the tubing and exits a perforated sub installed below a packer. The water then goes around the impact tool before entering the perforation, thus allowing the tool to operate while injection is ongoing.

Sucker rods or corods connect the top plunger to the pumping unit. The installation has a standard stuffing box on the tubing to prevent leaks of wellbore fluids and it has a downhole amplifier for enhancing the discharged shock wave.

To prevent a pumping unit from encountering or even approaching a zero load, ASR codeveloped a dampening system with engineers from a current field installation and incorporated it as part of the tool.

Fig. 2 shows that the pumping unit bears a baseline load averaging 6,000 lb on the downstroke and the load gradually rises to 16,000 lb on top of the upstroke. At that moment the “firing” occurs, the unit experiences a momentary drop of 3,000 lb below the baseline load as a result of rod string inertia relaxation. But this is still above the zero load that could sooner or later damage the pumping unit.

The harmonics following release of the shockwave are attributed to rod string compression-relaxation cycles.

The shockwaves traveling at 1.5 miles/sec cover distances of more than 1 mile and propagate in all directions to eventually become elastic waves. These shock-elastic waves mobilize oil that otherwise would never have moved.

Enhancing oil recovery

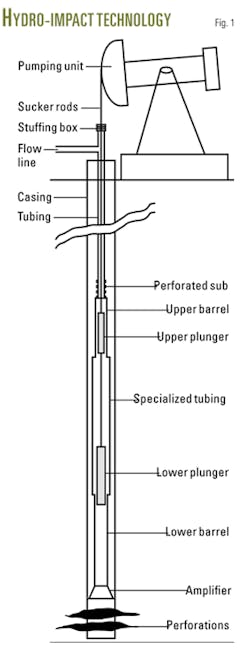

Several possible mechanisms could explain the extraction of oil from reservoirs affected by shock-elastic waves, but the authors feel the most plausible mechanisms are:

• The dislodging of oil droplets from the pore wall (Fig. 3a). The dislodged droplet becomes mobile and moves into the flow of fluids.

• Coalescence of two or more small immobile oil droplets or oil films surrounding the formation grains into larger droplets which in turn create a “stream” having higher mobility sufficient to move into the flow of fluids (Fig. 3b).

Work performed by the Los Alamos National Laboratory13 19 20 determined that pore pressure fluctuations as low as 70 Pa (0.01 psi) mobilized fluids. The 3,000-psi or greater pressure on the front of the shock wave generated by the impact tool, therefore, is sufficient to dislodge or coalesce oil droplets at long distances even when the shock wave undergoes an attenuation in the formation.

Reference 21 describes in greater detail both mechanisms.

The Railroad Commission of Texas granted Occidental Permian Ltd. and all other Texas oil and gas operators tax incentives to employ in situ impact tools as an enhanced oil recovery technology.

Suitable fields

Since the late 1990s, analyses using a proprietary computer model have determined that 70-80% of the 50 fields studied were suitable for in situ impact simulation. These fields include sandstone, carbonate, diatomite, waterflood, and natural water drive reservoirs, as well as one oil reservoir with gas injection.

The efficiency of the stimulation increases if the reservoir contains regions of unswept or bypassed oil. That is to say, the more unswept or bypassed regions in the reservoir the higher is the probability of increasing oil production rates and total recovery.

The presence of free gas in a reservoir dampens or attenuates the elastic wave and correspondingly lessens the stimulation efficiency.

Many different opinions exist on why seismic stimulation works in some cases and does not in others.

ASR has stimulated a wide variety of formations including Samotlor sandstone in West Siberia, Russia; Strawn sand in North Texas; Kern River formation in California; Permian basin reservoirs in Texas; Lost Hills diatomite in California; Poza-Rica reservoirs in Mexico; Elk Hills sandstone in California; Tensleep formation in Wyoming; and other reservoirs with similar properties.3

These formations have 0.1-2,000 md permeability, 10-50% porosity, 11-38° oil gravity, and 20-5,000 scf/stb GORs. ASR found the oil gravity and GOR were the only essential inter-dependent properties of the oil-bearing formation and the efficiency of in situ seismic stimulation.

The authors feel that any formation having unswept or bypassed oil-bearing productive layers with a 17° or greater oil gravity and a 2,000 scf/stb or less GOR would benefit from this stimulation.

The computer program to determine the suitability of the impact stimulation requires the following data:21

• Cumulative oil and water production.

• 3-4 years of monthly oil and water production.

• A few core and fluid properties analysis and if available spinner log surveys.

Lost Hills stimulations

Characteristics of the Lost Hills diatomite formation include a 0.1-2 md average permeability, 45-55% average porosity, 2,200-3,700 ft productive depth, 30% average oil cut, 28° oil gravity, and 800 average GOR. The computer model has shown the presence of 30-40% noncontributing sublayers of the entire pay zone that qualifies Lost Hills diatomite as a good to excellent choice for stimulation.

Fig. 4a shows Operator 2’s stimulation of one section of the Lost Hills started in October of 2001 and continued uninterrupted until May 2002. The data in Figs. 4a and 4b are from Operator 1’s wells that were influenced by Operator 2’s stimulation in the same section of the Lost Hills diatomite.

A key observation in Fig. 4a is that Operator 2’s stimulation increased oil production and leveled off water production. Fig. 4a also shows that oil production returned to a historical decline after Operator 2 stopped the stimulation activity.

Once Operator 1 began the impact stimulation in one of its own wells, its oil production began to depart from the historical decline curve and water production began a downward trend to a lower, stabilized level.

Fig. 4b displays another response to in situ seismic stimulation. The figure shows a semipermanent to permanent enhancement in oil recovery as seen in the slope change of the oil-cut curve that continued for 15 months until the start of Operator 1’s stimulation activity.

ASR has noted that this behavior in the diatomite is not unique because long-lasting changes in the oil-cut curve also occur in Permian basin carbonate reservoirs.

Operator 1’s single impact tool currently provides stimulation to Operator 2’s wells.

Elk Hills stimulation

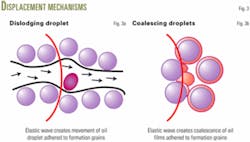

Characteristics of the Elk Hills sandstone included a 30-400 md average permeability, 32-39% average porosity; 2,800-3,100 ft productive depth, 15% oil cut, 19-28° oil gravity, and a 800 scf/stb average GOR.

A computer model has shown the presence of 25-30% noncontributing sublayers of the whole pay zone, making the zone a good candidate for in situ seismic stimulation. As a result of the computer analysis, Oxy installed two impact tools in the field.

Fig. 5a shows that based on average well test data for 73 wells within a 1⁄2-mile radius the two tools increased oil production from an average 1,556 b/d in December 2003 to the current 2,212 b/d in December 2004.

During this same period, oil cut increased to 21.6% from an average 16.8%.

Fig. 5b plots total oil and water production for the 73 wells. It shows:

• Stable water production and an increase in oil production.

• An increase of water production with an increase in oil production.

• Decline in water production with continuing increase in oil production.

Figs. 6a and 6b show the area impacted by the in situ seismic tools. The red circles represent the first two tools installed along with their radius of influence.

The blue circles represent the locations and radii of influence of the three tools added in early November and fourth tool added in early December.

Lawrence Berkeley

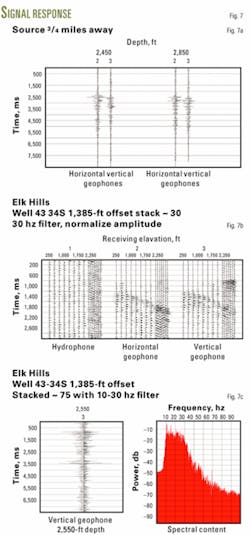

Lawrence Berkeley National Laboratory carried out numerous measurements of the impact tools signals in different oil fields at varied distances from the well in which the tool was installed (Figs. 7a-7c).

The measurements show that the signals at these distances are strong and considering the small pressure required to cause improvement in oil mobility, 13 19 2 it is not surprising that the wells located as far as 3⁄4 mile from the downhole tool respond positively to seismic stimulation.

Fig. 7a shows a strong signal from the source at 3⁄4 mile, indicating that the impact stimulation can potentially enhance oil recovery and increase production on wells located at least at 3⁄4 mile in all directions from the source in this field.

Fig. 7b shows hydrophone-geophone measurements made at a distance of 1,385 ft from the source.

Fig. 7c shows geophone measurements made at a distance of 1,385 ft from the source.

References

1. Kostrov, S.A., Dual Tubing Pump for Stimulation of the Oil-bearing Formation, US Patent 6015010, January 2000.

2. Kostrov, S.A., and Wooden, W.O., “Method and Apparatus for Seismic Stimulation of Fluid-Bearing Formations,” US Patent granted July 13, 2004, Application 10/132,371.

3. Kostrov, S.A., et al., “In situ Seismic Shockwaves Stimulate Oil Production,” OGJ, Sept. 3, 2001, p. 47.

4. Vagin, V.P., Method and Apparatus for Shock Wave Stimulation of Oil-Bearing Formations, US Patent 5586602, Dec. 24, 1996.

5. Harthy, A., et al., “Screen and Near-Wellbore Cleaning and Stimulation Tools Evaluation: Recent Experience in Well operation,” SPE Paper No. 89653, Coiled Tubing Conference and Exhibition, Houston, March 2004.

6. Beresnev, I., and Johnson, A., “Elastic-Wave Stimulation of Oil Production: a Review of Methods and Results,” Geophysics, Vol. 59, No. 6, 1994, pp. 1000-17.

7. Champion, B., et al., “The Application of High Power Sound Waves for Wellbore Cleaning,” SPE Paper No. 82197, European Formation Damage Conference, The Hague, May 2003.

8. Fracteau, D.M., Fluidic Oscillator, US Patent 5893383, Apr. 13, 1999.

9. Ganiev, R.F., et al., “Wave Mechanism of Fluid Acceleration in Capillaries and Porous Media,” Transactions (Koklady), USSR Academy of Sciences, Vol. 306, No. 4, 1989, pp. 803-06.

10. Ganiev, R.F., et al., Wave Technology, Logos, Moscow, 1993, pp. 49-58.

11. Huffman, A.R., et al., Process and Apparatus for Coupled Electromagnetic and Acoustic Stimulation of Crude Oil Reservoirs Using Pulsed Power Electrohydraulic and Electromagnetic Discharge, US Patent 6227293, May 8, 2001.

12. Melson, A.F., et al., Method for Stimulating Hydrocarbon Production, US Patent 6390191, May 21, 2002.

13. Patzner, N., Method and Apparatus for Cleaning Wells with Ultrasonics, US Patent 5727628, Mar. 17, 1998.

14. Soliman, M.Y., et al., Method and Apparatus for Treating a Wellbore with Vibratory Waves to Remove Particles Therefrom, US Patent 6619394, Sept. 16, 2003.

15. Wegener, D.C., et al., Methods and Apparatus for Enhancing Well Production Using Sonic Energy, US Patent 6186228, Feb. 13, 2001.

16. Wong, S.W., et al., “Near Wellbore Stimulation by Acoustic Waves,” SPE Paper No. 82198, SPE European Formation Damage Conference, The Hague, May 2003.

17. Nikolaevskiy, V.N., et al., “Residual Oil Reservoir Recovery with Seismic Vibrations,” SPE Production & Facilities, No. 5, 1996, pp. 89-96.

18. Kurlenya, M., and Serdyukov, S., “Reaction of Fluids of an Oil Producing Stratum to the Low Intensity Vibro-Seismic Action,” Journal of Mining Science, Vol. 35, No. 2, 1999, pp. 113-19.

19. Majer, E., et al., “Laboratory and Field Observations of Stress-Wave Induced Changes in Oil Flow Behavior, Expanded Abstracts,” SEG Meeting, 2001.

20. Roberts, P., and Sharma, A., “Low-Frequency Acoustic Stimulation of Fluid Flow in Porous Media,” Journal of Acoustic Society of America, Vol. 105, No. 2, Part 2, 1999, p. 1385.

21. Kostrov, S., and Wooden, W., “Mechanism, Field Suitability and Case Studies for Enhancement of Oil Recovery and Production Using In Situ Seismic Stimulation,” 16th International Symposium on Nonlinear Acoustics, Moscow, Aug. 19-23, 2002.

The authors

Sergey A. Kostrov is technical director for Applied Seismic Research Inc., Plano, Tex. He has been involved with theoretical and experimental investigations into the affect of elastic waves on mass-transfer processes in multiphase media. Kostrov holds an MS in mechanics of high-speed processes from Moscow State Technical University and PhD in fluid mechanics from the Mechanical Research Institute of the Russian Academy of Sciences. He is a fellow of the Russian Academy of Sciences, Moscow.

William O. Wooden is vice-president of Applied Seismic Research Inc., Plano, Tex. He has a background in sales and marketing of emerging technology. Wooden has a BS in sciences and engineering from the University of Oklahoma.