Drilling Market Focus: Drilling boom continues worldwide

Drilling activity and rig counts continue to climb worldwide, despite increasing day rates and the cost of steel tubulars.

Houston-based Raymond James energy analysts J. Marshall Adkins and James M. Rollyson noted in a mid-March energy update that operators are taking a long-term focus due to concerns about offshore rig availability. Recent contracts specify “significantly higher day rates than [Wall] St. had been modeling,” fueling their speculation that rates will continue to trend upward.

Rig counts

Baker Hughes Inc.’s North American rig count for Apr. 1, 2005, showed 1,559 rigs operating, up 205 rigs from a year ago (up 15%).

There were 230 rigs operating in Canada, down 86 rigs from a week ago (-27%), due to warmer weather and an early thaw.

The US rig count was at 1,329, up 169 rigs (up 15%) from a year prior, and well above the rig count bottom on Apr. 5, 2002. The weekly count includes 1,206 land rigs, 94 rigs offshore, and 29 in inland waters (up from 15 a year ago).

Texas leads nationally with 588 rigs, down 5 from the week before, representing a 17% increase compared with the prior year. US states with increased drilling are New Mexico (79 rigs, up 2 from the week before, and up 14 from a year earlier), and Oklahoma (155 rigs, up 2 from the week before, but down 3 from a year earlier).

The Gulf of Mexico rig count decreased to 90 from 91 the week of Apr. 1 but was up only 1 rig from a year earlier.

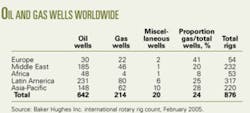

According to Baker Hughes, the international rotary rig count was 876 in February 2005, including 623 land rigs and 253 offshore rigs. The February count was up 16 rigs from the month before, and up 86 rigs from a year earlier. The table shows that the rigs were differentiated as drilling for oil (642), gas (214), and miscellaneous (20).

Regionally, Europe had the highest percentage of rigs drilling for gas (41% of all wells) and Africa had the lowest (7.5% of all wells). The international average was 24% of all rigs drilling for gas.

Two regions lost working rigs from the previous month: Europe (54 rigs, down 3) and the Middle East (232 rigs, down 10).

Three regions gained rigs from the previous month: Africa (53 rigs, up 3); Latin America (317 rigs, up 10); and Asia-Pacific (220 rigs, up 16).

Transocean

Robert L. Long, president and CEO of Transocean Inc., the world’s largest deepwater drilling contractor, spoke in mid-March at the A.G. Edwards & Sons energy conference in Boston. He noted that availability of deepwater floaters is limited through 2006 and that new contracts are of longer duration and command higher day rates. He expects no new deepwater rigs coming into the market, citing newbuild construction costs as an impediment.

Long sees utilization of other floaters improving in the UK North Sea and in the Gulf of Mexico, and the company has reactived four semisubs in these areas: the Sedco 706 and 712 in the North Sea; and Transocean Amirante and Falcon 100 in the Gulf of Mexico. A fifth semisub, Transocean Legend, is also reactivated and was moving from Brazil to Asia-Pacific in March.

Long said utilization is high and day rates are improving for Transocean’s 26 jack up rigs. The speculative newbuilds scheduled to come on the market in late 2006-early 2007 are only a “modest concern,” but he does have doubts about the market’s ability to absorb 25-35 new jack ups without lowering day rates.

Transocean updated its fleet contract status on Mar. 31, 2005. Notable new contracts among the 93 offshore drilling units include: Discoverer Spirit drillship under contract to Royal Dutch/Shell for the Gulf of Mexico (September 2005 - March 2007 for $270,000/day, up 32% from $204,000/day); Jim Cunningham semisubmersible under contract to BG Group PLC for Egypt (September 2005 - March 2006 for $155,000/day, up 138% from $65,000/day); Sedco 703 semisub under contract to BHP Billiton Ltd. for Australia (July 2005 for $135,000/day, up 63% from $83,000/day); and the Sedco 706 under contract to Total SA for the UK North Sea (January-December 2005 for $78,000/day, up 37% from $57,000/day).

SCORE

On Mar. 21, GlobalSantaFe Corp. reported that the company’s worldwide SCORE (summary of current offshore rig economics) for February 2005 was 60.8, up 4.6% from the previous month. The worldwide SCORE is up 135% from 5 years earlier.

Regionally, the SCOREs for the North Sea (up 8.4%) and the Gulf of Mexico (up 5.7%) showed the largest gains from the previous month. The SCORE for the Gulf of Mexico showed the largest year-over-year increase (64%) and the North Sea showed the largest 5-year increase (233%).

The SCORE for jack ups continues to increase, reaching 61.6 in February 2005 after a low of about 44 in September 2003. The February jack up SCORE is up 19% from a year earlier and up 117% from 5 years earlier.

The SCORE for semisubmersibles was 60 for February 2005, up 67% from a year earlier and up 160% from 5 years earlier. The semisubmersible SCORE hit a low of about 31 in February 2002.

GSF’s SCORE compares the “profitability of current mobile offshore drilling rig day rates to the profitability of day rates at the 1980-81 peak of the offshore drilling cycle.”

Offshore day rates

ODS-Petrodata Inc. publishes monthly worldwide competitive day rate indices in four offshore rig categories, based on the average market day rate in January 1994 equal to 100.

For March 2005, the US Gulf of Mexico jack up index was 207, having increased steadily from a little over 100 in March 2003. The index has doubled in the past 2 years, and “rig owners are likely to be able to command higher day rates in the coming weeks.”

The North Sea jack up index was 244 for March 2005, unchanged from February, representing a stable market. Although rates are not expected to change in the near-term, ODS-Petrodata predicts that North Sea jack up rates will rise later in the year.

The deepwater (floating rig) index was 340 for March 2005, rising from less than 200 in September 2004. The worldwide fleet is fully utilized, rates of more than $300,000 are under discussion, and “rig owners are in the driver’s seat,” with rates and the index expected to rise.

The mid-water depth semisubmersible day rate index was 291 for March 2005, down from about 325 in February. Based on utilization above 90% for 4 consecutive months and a new semisub contract negotiated in February for $245,000/day, company analysts expect day rates to increase.

At the end of February, Smedvig ASA announced a letter of intent to lease a rig still under construction, the company’s self-erecting semi-tender rig, West Setia. The new semi-tender will be delivered in August 2005, and Murphy Sabah Oil Co. Ltd. seeks an 800-day contract to begin in September or October 2006. The West Setia would be used to drill production wells in combination with the recently announced spar platform in the Kikeh field offshore Block K, Malaysia, the first use of tender-assisted drilling on a spar platform. Kikeh will be the country’s first deepwater field, about 1,330-m water depth, off Sabah.

Technip is designing the spar, which will be the first one installed outside the Gulf of Mexico. The topsides will have a 25-slot well bay for dry tree wellheads.

The $60 million contract for the West Setia ($75,000/day) is subject to approval by Petronas Bhd.

New joint charters

Statoil leads a new partnership for long-term drilling mobile rig charters, announced in late March. The consortium, which includes Norsk Hydro ASA, Eni Norge AS, Norske Shell AS, and Statoil, will try a new collective business model for joint chartering of multiple rigs.

Statoil has had prior experience with partnership contracts for single rigs, including the Ocean Vanguard, Eirik Raude, and the Transocean Leader in 2004.

On Mar. 21, 2005, Smedvig ASA announced a letter of intent for new contract from Statoil for its West Alpha semisubmersible. The rig will be used for drilling on the Norwegian continental shelf. The $273 million, 3-year contract will begin in February 2006 and represents about $249,000/day.

Smedvig CEO Kjell E Jacobsen said these are “very exciting times for our industry.”

On Mar. 22, Statoil announced taking contracts for two rigs from Transocean on behalf of the consortium. The Transocean Arctic and Polar Pioneer would be under 1-year contracts worth $200 million, to begin third-quarter 2006.

Arne Tillerli, Statoil’s project manager for the cooperation agreement, said that it “provides good access to qualified rig capacity without the companies being forced to accept a disproportionately high level of financial risk for the charters.”

New land rigs

Akita Drilling Ltd. and Doyon Drilling Inc. formed a joint venture to build a new arctic rig for winter drilling. On Mar. 15, 2005, Doyon Akita JV announced a 4-year contract with Pioneer Natural Resources Co. to build and operate the lightweight exploration rig on Alaska’s North Slope.

The fit-for-purpose rig will be built in Canada in mid-2005 and begin drilling later in the year. Pioneer said that using the new rig should reduce drilling costs, in particular ice road construction and mobilization costs.

Pioneer has extensive, undeveloped acreage on the North Slope, and announced a $50 million 2005 Alaska exploration program in the National Petroleum Reserve, the Storms Lead area, and the Tuvaaq offshore lease, a 14,000-acre block northeast of Pioneer’s Oooguruk Unit.

KCA Deutag Drilling Ltd. CEO Maurice White told OGJ in late February that the company has two Kremco Sandmaster self-propelled land rigs under construction at National Oilwell Varco’s Edmonton facility. One is a 1,200-1,500 hp drilling rig constructed at a cost of $8-9 million, and the other is a 750-hp workover rig, constructed for $5-6 million. Both rigs are slated to work in Libya, the first to arrive there in March-April 2005.

KCA Deutag will have 17 rigs in Libya with the new additions (Fig. 1).

New jack ups

On Mar. 18, Keppel FELS Ltd. reported a new $121-million contract to build a second jack up for Odfjell Drilling AS. Bergen, Norway-based Odfjell signed a contract for a KFELS modified V-B Class jack up in March 2004 and exercised its option for a second jack up in March 2005.

Both rigs will be capable of drilling in water depths to 350 ft and drilling down to 30,000 ft. The first jack up (B265) will be delivered second-quarter 2006 and the new jack up will be delivered in second-quarter 2007.

On Mar. 14, KFELS reported contracts with A.P. Moller-Maersk AS for four new CJ 50-design jack ups, worth S$596 million. Marine Structure Consultants BV, based in Schiedam, the Netherlands, designed the CJ 50 rigs, which can drill in 350-ft water and drill high-pressure wells to 30,000 ft (Fig. 2). The three-legged cantilever design has a hull 68 m x 70 m and legs 162-m long.

The first of the four will be delivered fourth-quarter 2007, and the other three at 6-month intervals.

Well service rig fleet

Weatherford International Ltd. and the Association of Energy Service Cos. (AESC) publish a monthly well service rig count. In February 2005, there were 2,144 rigs active in the US and 837 in Canada, for a total of 2,981 in North America. This represents 66% of the US well service rigs in the US (up 4% from a year earlier) and 84% in Canada (same as a year earlier); overall 70% utilization in North America (up 2% from February 2004).

The largest increases in service rig count were in the West Texas-Permian Basin (719 active rigs, up 53 rigs from a year earlier) and in the Rocky Mountain area (319 active rigs, up 27 from a year earlier). Rig activity was slightly lower in the eastern US (down 3 rigs) and in the mid-continent (down 4 rigs) from a year earlier.

National Oilwell, Varco

Houston-based National-Oilwell Inc. and Varco International Inc. announced on Mar. 11, 2005, that stockholders approved their $2.5-billion merger. National-Oilwell shareholders will own 51% of the combined company and Varco shareholders 49% (OGJ, Aug. 23, 2004, p. 27). This follows a string of more than 30 company acquisitions in the past 5-6 years.

On Feb. 9, Varco presented fourth-quarter and yearend 2004 results. All four Varco business divisions had increased year-over-year fourth-quarter revenues (drilling equipment up 31%; drilling services up 29%; tubular services up 24%; coiled tubing and wireline products up 24%).

John F. Lauletta, Varco’s chairman and CEO, attributed part of the year’s success to the “aggressive restructuring of our drilling equipment group.”

On Feb. 25, National-Oilwell released fourth-quarter and yearend 2004 results. Revenues for the products and technology group were up 33% for the fourth quarter year-over-year, and up 11% for the distribution services group.

Merrill A. (Pete) Miller Jr., president and CEO of National Oilwell, said the company received $961 million in capital equipment orders in 2004 and “we believe 2005 will see new orders of capital equipment of at least $1.0-1.2 billion.”

The new company, National Oilwell Varco Inc., will design, manufacture, and sell land and offshore drilling and production equipment, and provide services for the upstream oil and gas industry. Lauletta is named chairman and Miller is named president, CEO, and director of the merged company.

CT acquisition

On Mar. 18, Willis, Tex.-based Grifco International Inc. (GFCI) announced a letter of intent to purchase a Texas-based coiled tubing company with a through-tubing jetting tool and new through-tubing jet motor design. GFCI says the through-tubing motor industry exceeds $500 million/year. President and CEO Jim Dial expects due diligence examination of the candidate will be complete by mid-May. GFCI offers coiled tubing, wireline, and snubbing services.

Earlier this year, GFCI announced two other acquisitions: on Feb. 17, an LOI to purchase Global Oil Tools Inc. for $4.5 million in cash and stock; on Jan. 18, completed purchase of KO-VAC Systems, previously announced on Dec. 6, 2004.

Supply boat market

On Mar. 14, New Orleans-based Tidewater Inc. announced that it signed a letter of intent to sell up to six of its KMAR 404 class anchor handling towing supply vessels to an international group for a total price of $202 million.

Chairman and CEO Dean Taylor said that the opportunity “reflects the overall improved level of drilling and exploration activity in the North Sea.”

Tidewater expects to take delivery of four new vessels in 2005.

According to 2004 results reported Mar. 3, 2005, by Fort Lauderdale, Fla.-based Seabulk International Inc., day rates for Gulf of Mexico supply boats averaged $5,421 for fourth-quarter 2004, up from $4,768 in the third quarter and $5,101 in fourth-quarter 2003.

Average day rates for the company’s fleet of towing supply and supply vessels in West Africa were $7,574 in fourth-quarter 2004, up from $7,300 in third quarter. The company’s day rates remained steady for the past year in the Middle East and Southeast Asia.

OSV company merger

The second and third largest offshore supply vessel (OSV) companies in the world, Houston-based Seacor Holdings Inc. (212 vessels) and Seabulk International (147 vessels), announced a $1 billion merger on Mar. 16, 2005.

The companies supply vessels for worldwide offshore exploration and production, as well as tankers and harbor tugs, inland river barges, and offshore aviation services.

Seacor Marine’s diversified fleet has been focused on deepwater exploration in the US and North Sea.

Seabulk operates in more than 25 countries and has three main businesses: Seabulk Offshore (110 vessels), Seabulk Tankers (12 vessels) and Seabulk Towing (26 vessels). According to a Jan. 25 press release, Seabulk recently took delivery of 2 new vessels, Seabulk Angra and Seabulk Advantage, among the 9 new vessels added to its fleet in the past 2 years. Seabulk has 2 more newbuild vessels due for delivery in 2005 and 2 others in 2006.

The merger has been approved by both companies’ boards and is expected to close by the end of second quarter 2005. The combined fleet will still be smaller than that of OSV market leader Tidewater Inc., which controls about 560 vessels.

Tubulars

Most of the world buys tubular products from mills. In the US, tubulars are purchased primarily from intermediaries. Mills specify output in tonnage (tonnes), which can be directly correlated to steel prices, while the oilfield tends to refer to oil country tubular goods (OCTG) in terms of length (footage).

According to UK-based MEPS International Ltd., world carbon steel prices for merchant bar increased 92% to $566/tonne in December 2004 from $295/tonne in January 2003.1

Steel prices continue to affect the overall cost of wells. Drill pipe and some tubing strings can be reused, but casing and liners are left in the hole. Using expandable liners can reduce the number of casing strings that would be required using conventional pipe.

Most pipe is carbon steel, but chrome and “super chrome” are used in many situations. Lightweight carbon- fiber composite pipe was developed in a $2.82 million, 5-year DOE project but is still about three times the cost of steel pipe.2

William M. Griffin Jr., vice-president of onshore and offshore divisions at El Paso Production Co., testifying July 15, 2004, at an oversight hearing for the US House of Representatives Subcommittee on Energy and Mineral Resources said, “pipe supply and prices have become a critical short-term issue for the industry.”

Deep wells on the Gulf of Mexico shelf can require large diameter, thick pipe and may have to be made of exotic alloys to handle high temperature, pressure, or sour gas. “The overall backlog in manufacturing pipe has created delays as long as 6 months,” Griffin said.

Tenaris is in the seventh year of a 9-year contract with ConocoPhillips to provide tubular goods worldwide, with contracts for more than 30,000 tonnes/year of pipe, according to the February 2005 issue of TenarisNews. ✦

References

1. www.meps.co.uk/World%20Carbon%20Price.htm

2. PTTC Network News, fourth-quarter 2003.