Xylene-based inhibitor solves crude oil wax problems in Niger Delta pipeline

Xylene-based inhibitor solves crude oil wax problems in Niger Delta pipeline

Experiments in both laboratory and field flow systems in Nigeria have tested the effectiveness of a xylene-based inhibitor for solving wax-deposition problems in pipelines. The formulation has a good wax-deposition inhibiting, pour-point depressing, and viscosity-reducing effect for the tested crude oils.

The field results presented here reveal its economic benefit for waxy crude oil pipeline flow and wax deposition problems throughout the Niger Delta.

Waxy crudes

Crude oils from Niger Delta formations move in long-distance pipelines in which solid wax particles may precipitate and deposit. This is a problem in any oil field producing paraffinic crude oils.

Wax formation and deposition reduce pipeline throughput. More important, the pumping costs are higher because reduced pipe diameter increases pipe wall friction. Numerous methods have been used to control the formation, deposition, and buildup of wax during production and transfer operations.1-5

null

A combination of methods frequently is used to prevent this wax precipitation and accumulation.

The industrial cost involved in preventing wax deposition is high, and the petroleum industry is always looking for a cheap and effective additive to control the problem. Most research has been targeted at studying the processes of wax precipitation and accumulation independently.6-13

Nigeria's oil industry has always faced significant wax deposition and crude oil pipeline transportation problems.3 14-17 Fig. 1 shows typical blockage.

This article provides field evaluation and performance data for a newly developed xylene-based wax inhibitor with respect to flow properties and deposition problems in the Niger Delta.

Laboratory screening, lab tests

Six chemicals (trichloroethylene, cyclohexanone, MEK, acetone, hexane, and xylene) were screened by use of the cold-spot method for their wax deposition-inhibiting capabilities and best pour-point depressing properties of a stock tank crude oil sample from the Niger Delta. The screening test revealed that the trichloroethylene-xylene (TEX) binary system performed most efficiently and was therefore chosen for further tests.

The ability of the TEX-based system as wax-deposition inhibitor and flow improver was further investigated on another three sets of stock tank crude oil samples from the Niger Delta area.

The initial wax contents of these samples were 22.17%, 25.75%, and 32.50%, while the wax-inhibition efficiency was estimated to be as high as 92% for different concentrations of the newly developed inhibitor. The pour point of the three crude oil samples was also significantly reduced. Detailed information on the testing protocol and experimental results has been presented elsewhere.16

Field application

The xylene-based inhibitor was field tested in an oil field installation with severe paraffin deposits and pipeline transportation problems. The chemical was injected at a designated point along the flow line.

Crude oil sampling at both the upstream (near wellhead) and downstream (manifold) locations of the injection point were carried out daily for 12 days.

The injected chemicals were evaluated on the relative magnitude of the pour point, viscosity, and API gravity of the produced crude before and after chemical treatment. Tests were also conducted on corrosiveness and compatibility of each chemical with freshwater, DEA solution, and demulsifiers.

Field test results

Fig. 2 shows the pour point trends of both the untreated and chemically treated flowlines. The plots show the xylene-based inhibitor has a depressing effect on the pour point and hence the waxing tendency of the crude.

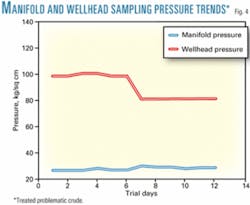

Comparison of the pour point of the chemically treated crude with the temperature condition of the downstream (manifold) sampling location shows that the fluid temperature is generally lower than the pour point of the crude (Fig. 3). This condition may tend to promote wax deposition from the crude.

The observed free flow pattern, the stabilized pressure condition, and the downstream sampling location (Fig. 4), however, indicated no wax deposition. The authors feel that was due to excellent wax crystal modification properties of the inhibitor.

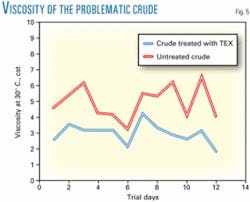

Fig. 5 shows the effect of xylene-based inhibitor on the viscosity of crude oil in the flowline. The trends show a reducing effect, indicating the xylene-based inhibitor improves the flow characteristics of crude oil in the flowline under field conditions, consistent with the laboratory test results.16

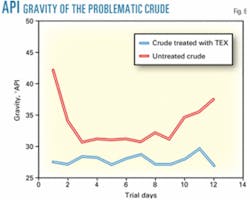

The API gravity trends presented in Fig. 6 show that treatment of crude oil in the flowline with xylene-based inhibitor caused a significant increase in the crude's API gravity over the 12-day test period, consistent with the previous test results. These increases were more than 2°, reaching up to 6° or more on some days.

These trends reaffirm the capability of the product to achieve improved flow characteristics of this problematic crude.

The pour point, viscosity, and API gravity observed for the field test indicate that the xylene-based inhibitor demonstrated a good performance and great potential for inhibiting wax deposition and achieving improved flow characteristics of the crude at the fairly low chemical dosage of less than 60 ppm.

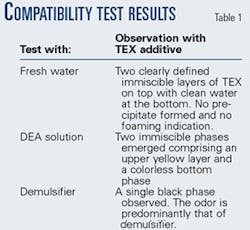

The copper-string corrosion test on the product ruled out corrosive behavior by giving a negative response. Table 1 provides a brief description of the observation made when xylene-based inhibitor contacted freshwater, DEA solution (26%), and a demulsifier.

The xylene-based inhibitor is completely insoluble in water, ensuring that any chemical injected will go into oil phase where it is needed. It also rules out the possibility of colloidal formation and the foaming phenomenon commonly observed with other antiparaffin chemicals.

The xylene-based inhibitor also had no detrimental effect on the demulsifier. In all cases, the xylene-based inhibitor provided a workable and cost-effective alternative to some of the currently patented wax inhibitors used in the Niger Delta area.

Inhibition mechanism

The wax deposition-inhibiting action of the xylene-based inhibitor is attributed to its interaction with the forming wax aggregates. The xylene-based inhibitor has structures with segments that interact with the forming wax crystal and prevent wax crystal growth.

The waxes in crude oils are paraffinic and vary in amount and molecular weight distribution. When waxy crudes are cooled down, the paraffinic wax starts to crystallize in the form of thin plates, needles, or microcrystals. As wax components come out of solution, the needles compact into a three-dimensional network.

Plates curl on their edges, forming hollow needles that can then network. In the present investigation, the xylene exhibited good performance as wax deposition inhibitor and flow improver because of the release of a free anion upon hydrolysis or dissociation.

In addition to this, an ionic pair of electrons present on the trichloroethylene compound also facilitates greater adsorption of the inhibitor molecules onto the wax crystal networks and prevents the interlocking of the three-dimensional wax networks.

The inhibitor molecules saturate the space within the wax crystal structures by producing a high ohmic resistance on the wax crystal's surface, rendering the surface unsuitable for the interlocking of the three-dimensional wax networks. The ability to form a stable suspension in the crude oil makes the inhibitor effective at concentration in the parts-per-million range, compared to the concentration of the wax crystals.

Acknowledgments

The authors acknowledge the special assistance of the late Victor Adewusi of Obafemi Awolowo University, Ile-Ife, Nigeria, for his contributions and reflections at the inception of this study.

References

1. Azevedo, L.F.A., and Teixeira, A.M., "A Critical Review of the Modeling of Wax Deposition Mechanisms," Petroleum Science and Technology, Vol. 21 (Nos. 3 and 4), 2003, pp. 393-408.

2. Dafan, Y., and Zheming, L., "Rheological properties of Daqing crude oil and its application in pipeline transportation," SPE No. 14854, 1986.

3. Fasesan, S.O., and Adewumi, O.O., "Wax Variation in Some Nigerian Oil wells in Delta Field," Petroleum Science and Technology, Vol. 21 (Nos. 1 and 2), 2003, pp. 91-111.

4. Hammami, A., and Raines, M.A., "Paraffin Deposition from Crude Oils: Comparison of Laboratory Results to Field Data," SPE Journal, March 1999.

5. McClaflin, G.G., and Whitfill, D.L., "Control of Paraffin Deposition in Production Operations," SPE No. 12204, presented at the annual conference and exhibition, San Francisco, Calif., Oct. 5-8, 1984.

6. Garcia, M.C., "Paraffin Deposition in Oil Production," SPE No. 64992, presented at the SPE International Symposium on Oilfield Chemistry, Houston, Feb. 13-16, 2001.

7. Garcia, M.C., Carbognani, L., Urbina, A., and Orea, M., "Paraffin Deposition in Oil Production," Oil Composition and Paraffin Inhibitors Activity, Petroleum Science & Technology, Vol. 16 (Nos. 9 and 10), 1998.

8. Garcia, M.C., Carbognani, L., Urbina, A., and Orea, M., 2000. "The Influence of Alkane Class –Types on Crude oil Wax Crystallization and Inhibitors Efficiency," Petroleum Science and Engineering, Vol. 25 (Nos. 9 and 10), 2000, p. 99.

9. Mendell, J.L., and Jessen, F.W., "Mechanism of Inhibition of Paraffin Deposition in Crude Oil Systems," SPE No. 2868, presented at the biennial Production Techniques Symposium, Wichita Falls, Tex., May 14-15, 1970.

10. Shock, D.A., Sudbury, J.D., and Crockett, J.J., "Studies of Mechanism of Paraffin Deposition and Its Control," Journal of Petroleum Technology, Sept. 7-23, 1955.

11. Wang, K-S., Wu, C-H, Creek, J.L., Shuler, P.J., and Tang, Y., "Evaluation of Effects of Selected Wax Inhibitors on Paraffin Deposition," Petroleum Science and Technology, Vol. 21 (Nos. 3 and 4), 2003, pp. 369-79.

12. Zhang, F., "Application of Pour Point Depressant for Crude oil in Long Distance Pipeline Transportation of China," Oilfield Chemistry, Vol. 16 (No. 4), 1999, pp. 268-71.

13. Dong, L., Xie, H., and Zhang, F., "Chemical Control Techniques for the Paraffin and Asphaltene Deposition," SPE No. 65380, presented at the SPE International Symposium on Oilfield Chemistry, Feb. 13-16, 2001, Houston.

14. Adewusi, V.A., "Prediction of Wax Deposition Potential of Hydrocarbon Systems from Viscosity-Pressure Correlations," Fuel, Vol. 76 (No. 12), 1997, pp. 1,079-83.

15. Adewusi, V.A., "Waxing Tendencies and Rheological Evaluation of Crude-Condensate Blends for Offshore Pipeline Transportation," Petroleum Science and Technology, Vol. 16 (No. 7 and 8), 1998, pp. 697-718.

16. Bello, O.O., Fasesan, S.O., Teodoriu, C., and Reinicke, K.M., "An Evaluation of the Performance of Selected Inhibitors on Paraffin Deposition of Nigerian Crude Oils," Petroleum Science and Technology, in press.

17. Fagbemi, A.S., "Report of Study on Wax Deposition Inhibitor," Obafemi Awolowo University, Ile-Ife, Nigeria, 1995.

The authors

Oladele Bello ([email protected]) is a staff engineer at the Institute of Petroleum Engineering (ITE), Technical University, Clausthal, Germany. His responsibilities include commissioning of multiphase flow and sand transport experimental facilities, research, and analysis. He previously conducted research on multiphase flow and flow improvers, multiphase transport phenomena in oil and gas production and transfer operations, and development of predictive software for multiphase multicomponent complex systems. Bello also is associated with the department of chemical engineering, Obafemi Awolowo University, Ile-Ife, Nigeria, where he specializes in modeling transport and deposition of sand particles during oil-gas multiphase production and pipeline transport. Bello is a member of American Institute of Chemical Engineers and Society of Petroleum Engineers.

Bayonile Ademodi is a an associate professor in the chemical engineering department, Obafemi Awolowo University (OAU) in Ile-Ife, Nigeria. He previously was a consultant working on the development of the tar sand and heavy oil resources of Nigeria and has undertaken several studies on heavy oil production, pipeline transportation, and upgrading. Ademodi teaches courses in petroleum reservoir and production engineering and supervises MSc and PhD theses on heavy oil recovery processes and pipeline transportation of heavy oil. He is a member of American Institute of Chemical Engineers.

Paul Akinyemi is head of the chemical engineering department, Lagos State University, Ojo, Nigeria. He works in the areas of flow assurance, rheology of crude oils, inorganic and organic scale deposition control, and modeling of transport and deposition of wax particles during oil-gas multiphase production and pipeline transport. He is a member of American Chemical Engineers and Society of Petroleum Engineers.