Calculating the perfect-well time

The following describes a technique that allows one to consistently calculate the physical limit for a particular drilling operation (and thus create well-cost estimates and identify opportunities for improvement) using a quick and simple technique that converts standard operational times and a specific energy to calculate the minimum time to drill an interval to a "perfect-well time." The perfect well time is a close approximation of the minimum time possible to drill a particular well, and can easily be calculated with a simple spreadsheet.

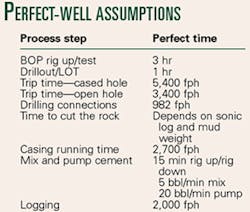

To define the "perfect well," engineers must step each hole interval through the process illustrated in the table. Note some steps may be deleted if there is no logging or casing, etc. The time required to accomplish each interval is then the sum of each 'perfect time' to accomplish each process step. The table summarizes the process steps; the section that follows describes how the sonic travel time is converted using specific energy concept into the fastest possible penetration rate.

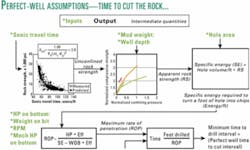

Time to cut the rock

The specific energy concept assumes that it takes a minimum amount of energy to cut a certain volume of hole. The time that it takes to cut a specific interval of hole depends on the horsepower being applied to the bottom hole.

Assuming a sharp bit and perfectly clean bottom of the hole, there is a maximum rate that rock can be cut. To estimate the minimum time to cut an interval of rock, one needs to know the horsepower applied to the bottom, the compressive strength of the rock, and the area of the bottom of the hole. The compressive strength of a rock is a function of the unconfined compressive strength and the mud weight. There is also a reasonable correlation between sonic travel time and unconfined rock strength.4 Both effects can be combined along with the hole size to determine the amount of minimum amount of energy it will take to a volume of rock.

The minimum energy assumes one perfectly sharp bit per hole section, perfect hole cleaning, and always exactly 100 psi overbalance. Knowing the horsepower applied to the bottom of the hole (which will depend on hole size and rig type), one can calculate the minimum time that a particular interval of rock could possibly be drilled3 5 (see illustration).