Japan undertakes ambitious hydrate drilling program

Japan will drill 16 shallow exploratory wells in deep waters off its coast, from Mie to Shizuoka prefectures, to determine the expanse and density of methane hydrate deposits.

Japan's Ministry of Economy, Trade and Industry (METI) announced in early January that this is part of a 16-year study, 2001-16, to determine whether methane hydrate is a viable commercial substitute for natural gas.

A consortium of Japan Petroleum Exploration Co. Ltd. (Japex), Japan National Oil Corp. (JNOC), and Teikoku Oil Co. will drill into the upper 300-400 m of sediment, in water depths from 700 m to 2,000 m. The consortium faces the challenges of deep water, strong currents, sediment instability, and hydrate dissociation.

Drillers will have to work in the Japan Current (Kuroshio) with a speed of 5-9 km/hr (3-5 knots).

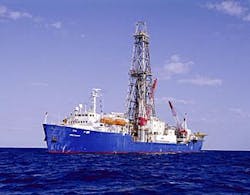

Yuichiro Ichikawa, general manager of the methane hydrate development division for Japan Drilling Co. Ltd. (JDC), told OGJ that the venture will use the JOIDES Resolution drillship, which arrived at Gamagori Port on Jan. 18 (Fig. 1). Japex has contracted with Overseas Drilling Ltd. (ODL), a joint venture between Transocean Inc. and DSND Inc., for use of the riserless drillship, which will then resume scientific ocean drilling under a 1-year contract for the Integrated Ocean Drilling Program (IODP) in June 2004 (OGJ, Sept. 22, 2003, p. 19).

Transocean manages the 469-ft long JOIDES Resolution, which drilled 1,742 holes as the primary platform for the Ocean Drilling Program from January 1985 (Leg 100) to September 2003 (Leg 210). The rig can suspend as much as 30,020 ft of drill pipe. JDC is responsible for conducting experiments during which it will drill and set casing in 2 of the 16 wells.

Tokyo University Professor Emeritus Shoichi Tanaka leads the Advisory Committee for National Methane Hydrate Exploitation Program within METI and developed the Methane Hydrate Exploitation Program. This program will be carried out by the Research Consortium for Methane Hydrate Resources in Japan (also known as the MH21 Research Consortium).

Frozen methane

Methane hydrate is a crystalline combination of water and methane that forms in low temperatures and high pressures. Hydrates consist of nano-structures in which the water molecules use hydrogen-bonding to form cages around gas molecules, resulting in an ice lattice. Hydrate accumulations are "clathrates"—compounds in which one component is physically enclosed within the crystal structure of another.

Hydrates form three types of structures: I, II, and H. Structure I, the most common, consists of biogenic methane. Structures II and H may contain thermogenic gas.

Prior hydrate drilling

Methane hydrate wells have been drilled on land in Canada's Mackenzie Delta in the northwestern Canadian Arctic, in Siberia, and in other permafrost areas. In the 1960s, natural gas hydrates were found in Siberian gas reservoirs. Only the Mackenzie Delta wells deliberately targeted hydrate; hydrates were recovered from the other wells as a byproduct of drilling for hydrocarbons.

The Ocean Drilling Program (ODP) and its predecessor, the Deep Sea Drilling Project (DSDP), and Japan's METI have encountered and sampled offshore hydrates. The JOIDES Resolution drillship did not attempt production from hydrates encountered. The Japanese, however, are comanaging the new Integrated Ocean Drilling Program (IODP), which succeeds the ODP, and they have built a new riser drillship, the Chikyu (OGJ, Sept. 22, 2003, p. 19).

In 1998, the Mallick 2L-38 gas hydrate research well was drilled to 3,773 ft in the Mallick gas hydrate field on Richard's Island in the Mackenzie Delta, NWT. The drilling was a collaborative project that included private companies, the Geological Survey of Canada, and JNOC. It utilized a mud system specifically designed for gas hydrates, including a mud-cooling system and a pressure-temperature coring system (PTCS).

JNOC and MITI (predecessor to METI) then went on to drill the first methane hydrate well offshore Japan. Based on bottom-simulating reflectors (BSRs) noted in a 1996 seismic survey of the Nankai Trough, they selected a well location in 3,100 ft water depth off Omaezaki Cape.

Japex subcontracted Transocean's M.G. Hulme Jr., a Friede & Goldman series 9500 enhanced pacesetter semi-submersible drilling unit capable of operating in up to 5,000 ft of water, that had been upgraded in 1998 (Fig. 2). The Nankai Trough well was drilled to 10,827-ft TD in November 1999.

There were two objectives: shallow gas hydrate, and a deeper, conventional hydrocarbon target. Gas hydrates were encountered and cored between 656 ft and 886 ft below the seafloor, but the deeper target was dry. The hydrate saturation was as much as 60% to 80% of available porosity.

Mallik wells

The Mallik partnership drilled a production test well and two observation wells in the Mallik field to more than 1,166 m. The production tests took place December 2001 through March 2002. The observation wells were used for cross-hole tomography experiments before, during, and after the production tests.

The Mallik partnership says this was the first modern production test of natural gas hydrates. Operators ran open-hole logs and recovered continuous wireline core through the hydrate intervals.

They used Schlumberger's MDT (modular formation dynamics tester) to measure formation fluid resistivity, temperature, hydrostatic pressure, and to recover fluid samples.

Results were reviewed in more than 60 oral and poster presentations at the Mallick International Gas Hydrate Symposium in Chiba, Japan (Tokyo area), Dec. 8-10, 2003.

The Mallik partnership includes: JNOC, Geological Survey of Canada (GSC), GeoForschungsZentrum Potsdam (GFZ), US Geological Survey (USGS), US Department of Energy (USDOE), India Ministry of Petroleum and Natural Gas (GAIL/ONGC), BP-Chev- ron-Burlington joint venture group, Japex, Japan Oil Engineering Co. Ltd. (JOE), the University of Tokyo, the University of Ottawa, the University of Victoria, the University of Calgary, the University of British Columbia, and the National Research Council of Canada.

The International Continental Scientific Drilling Program (ICDP) provides support.

US funding

The US Congress appropriated $47.5 million for 5 years of research in the Methane Hydrate Research and Development Act of 2000.1 This includes $5 million in 2001, $7.5 million in 2002, $11 million in 2003, and $12 million in each of 2004 and 2005.

In comparison, the oil and gas industry spends about $500 million/year on inhibitors, such as methanol or glycol, to avoid hydrate plugs in subsea pipelines, according to Prof. Walter G. Chapman, Rice University. He noted that a company has spent $48 million to insulate a single subsea pipeline.

Cornell University and Louisiana State University researchers spent 10 days in May 2003 studying natural methane hydrates in situ in the Gulf of Mexico. They descended 500 m to the seafloor in the Johnson SeaLink submersible.

Chinese Academy of Science member, Chen Duo Fu, from Guangzhou Institute of Geochemistry, Wushan, in South China's Guangdong Province, was an invited participant and the first Chinese researcher to descend to the sea floor. "We have seen man-made gas hydrates before in labs, but never in their natural environment," Chen said.

Reference

1. Methane Hydrate Research and Development Act of 2000 (H.R. 1753; Public Law 106-193). US code, Title 30, Chapter 31, Sec. 1902; May 2, 2000. http:// www4.law.cornell.edu/uscode/ 30/1902.notes.html