Mill cuts window, drills formation during sidetracks

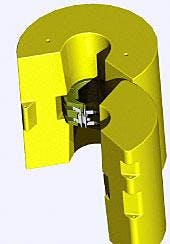

Here's the PathMAKER formation mill, a new window mill designed to mill a full gauge window and extended rathole, even in hard and abrasive formations.

It features special high-impact polycrystalline diamond compact cutters designed to cut metal and hard-abrasive formations like sandstone, anhydrite, limestone, and dolomite in one trip.

The specially engineered spiral set cutter alignment of the mill helps reduce vibration and provide smoother, cleaner cuts. The mill's profile and cutter placement control drilling fluid to cool and clean cutter elements efficiently.

The capabilities of the PathMAKER were displayed recently on casing exit cut in a dolimitic sandstone in Wyoming. The operator needed a window cut in 7 in., 32 lb/ft casing at 11,682 ft to perform sidetracking operations. The mill, run in hole on the WindowMaster G2 whipstock system and set in place on a TorqueMaster bottom trip anchor, cut a 12 ft window and 100 ft of open hole in 7 hr. The customer saved 2 full days of rig time compared with previous operations, the firm points out.

Source: Baker Oil Tools, 9100 Emmott Rd., Houston, TX 77040-3596.

New mixer is side entry version

A new petroleum side entry series mixer, made available to the industry recently, encompasses more than 50 years of mixer experience for process industries.

Sizing is accomplished via selection software developed specifically for petroleum operations, helping to ensure that precise mixer sizing is achieved based on specific application requirements.

With two sizes available in fixed and swivel angle arrangements, this firm can provide mixing solutions for blending, heat transfer, and crude oil bottom sludge and water control applications.

Features of the mixer include:

- Heavy duty construction.

- Timing belt drive.

- Power range of 15-50 hp.

Positive tank shutoff device with leak detector for seal change-out.

Source: Hayward Gordon Ltd., 6660 Campobello Rd., Mississauga, Ont. L5N 2L9.

Software offers sketching and modeling functionality

ALGOR V16, released recently, features new Superdraw 3D sketching and modeling functionality and 2D and 3D structured meshing tools within FEMPRO, an easy-to-use single user interface.

V16 also includes new mechanical event simulation capabilities for buckling and snap-through analyses; improved fluid flow, heat transfer, and linear dynamic analysis tools; and more result evaluation and presentation capabilities.

The new Superdraw 3D sketching and meshing tools allow engineers easily to construct and modify 2D and 3D sketches using CAD-like options including point move, split, intersect, fillet, trim, extend, rotate, scale, move, mirror, and parallel offset. A structured 2D or 3D mesh can then easily be created from these sketches through right-click options including three-point triangular, four-point rectangular, eight-point 3D, between two objects and four-object 3D meshing.

Source: Algor Inc., 150 Beta Drive, Pittsburgh, PA 15238-2932.

New distributed buoyancy module

This new, patent pending, distributed buoyancy module is designed to decrease installation time and complexity, as well as improve overall performance over the previous marketplace offerings.

Distributed buoyancy is used on flexible flowlines, umbilicals, and steel catenary risers to hold subsea lines in a configured shape. These configurations allow the floating production facility free range of motion at the surface without putting undue stress on the subsurface lines.

This module's design criteria includes easier installation, improved performance over a 20 year life span, and an increase in on-vessel safety during installation. This new product features a hinge and latch buoyancy element that offers easier handling and installation, a W shaped spring member on the internal clamp that allows for a larger variation in riser OD and improves long term performance, and a hinged internal clamp that eases installation and eliminates the need for pretensioning tools.

Source: Flotation Technologies Inc., 432 Elm St., Biddeford, ME 04005.