Equipment/Software/Literature

New compact mixer handles offshore jobs

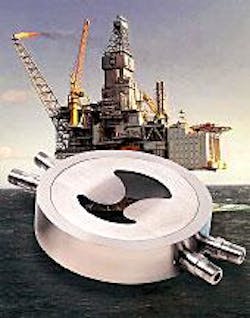

Here's a patented, compact, static mixer for offshore rigs and other applications requiring the blending of gases into liquids at high pressures and high temperatures.

The mixer is a compact, heavy-wall 316 stainless steel plate that fits inside the mating flange bolt circle of any piping system and thoroughly dissolves gases into liquids or mixes several liquids.

Capable of achieving >98% dispersion within 10 diameters downstream, this space-saving mixer comes in sizes for pipelines from 1/2 in. to as much as 96 in. diameter.

Featuring an orifice pattern that mixes by a combination of alternate vortex shedding and intense shear zone turbulence, the mixer is supplied standard with Flexitallic stainless steel high pressure gaskets.

It is hydrotested to customer requirements and ISO standards, radiographic tested to ANSI 31.1, and dye penetrant tested per ASME Section 5, Article 6.

Source: Westfall Mfg. Co., Box 7, Bristol, RI 02809-0007.

Sampling system handles waxy crude

Five of these Model 710 sampling systems were installed recently on pipelines in northeastern India to deal with crude oil consisting of about 14% wax and having a high pour point.

Electrically powered because of the absence of on-site pneumatic air and designed to comply with API 8.2 sampling standard, the systems are supplied with SC9 sample controllers.

The units complement nine existing sampling systems the company earlier placed in the area.

Elsewhere, an inline oil sampling system supplied by this firm has provided the accuracy required for export crude sampling on a North Sea platform, replacing a manual system with an automatic one.

Designed for low maintenance, the system consisted of a Model 210 sampler and SC9 safe area controller, plus automatic can change and Proserv sampling receivers with proximity sensors and included a logic interface panel for integration into the platform's controls.

The automatic pneumatic sample probe mechanically captures and ejects a nominal 1 cc sample at a grab rate of as much as 120/min.

It is fitted with a seal housing and ball valve permitting isolation and withdrawal from a pressurized line using the firm's hydraulic extractor. A relief valve prevents seal damage or sample leakage in the event of the receiver not being connected.

A 240 v ac heater with thermostat maintains a +30° C. temperature within the enclosure to prevent wax formation within the small bore tubing. The system was designed to be installed in an existing static mixer supplied by this firm on a previous project.

Source: Jiskoot Autocontrol Ltd., Tunbridge Wells, Kent, TN1 2DJ England.

Gas monitor alerts to CO or H2S

The T40 Rattler carbon monoxide or hydrogen sulfide single-gas monitor features the option for users to display text or numeric readings, user-adjustable low and high alarm settings, and adjustable calibration gas values.

The 3.5 oz unit's large liquid crystal display provides continuous real-time readings in parts per million or text display (safe-low-high), and when low and high alarm set points are exceeded the T40 will alert the user by activating audible, visual, and vibration alarms.

The compact, portable monitor is housed in a high visibility, impact-resistant case with what the company calls superior radio frequency interference protection for extreme work environments in oil and gas fields and refineries. A peak-hold feature, standard with all versions, captures and displays the highest recorded reading until it is cleared.

The unit features a flip-cap calibration routine (patent pending) for functional testing or full calibration using a pushbutton operation.

The monitor operates for as long as 500 hr on a single, field-replaceable AA alkaline battery and will alert the user to low battery life with audible and visual indicators.

The T40 carries UL, cUL, and ATEX certifications and is classified intrinsically safe for use in Class I, Groups A, B, C, and D (EEx ia IIc T4) hazardous locations.

Source: Industrial Scientific Corp., 1001 Oakdale Rd., Oakdale, PA 15071.