Marine pollution-protection system installed on first vessels

Last month saw the christening of the first oil tanker equipped with a preinstalled fast oil-recovery system for use in a shipwreck. The second so-equipped vessel is set for later this month.

More to come

System vendor JLMD Ecologic Group SA, Nice, says the system reduces the pollution resulting from damage to oil and chemical tankers, as well as ships holding large-capacity fuel tanks.

On Sept. 15, the Daewoo Shipbuilding & Marine Engineering (DSME) shipyards on Koje Island (Geoje), South Korea, were the site for the christening of the Valtamed, the first oil tanker equipped with the JLMD system, by Italian shipowner Navigazione Montanari (Tamoil).

The second christening was to have occurred the middle of this month in Tahiti by the French shipowner Socatra, with two additional tankers currently under construction, according to JLMD Ecologic.

null

By yearend 2004, said the company, 4 more vessels ships equipped with the JLMD system will be sailing international waters and, as of last month, another 30 ships were awaiting installation of the system. And, some 50 vessels, according to the company, primarily operated by Asian shipping agents, had orders pending.

"Hundreds of ships potentially equipped with the system over the next 2 years mean good news for marine environmental protection groups," said JLMD Ecologic in a release announcing the system's first installation.

The system

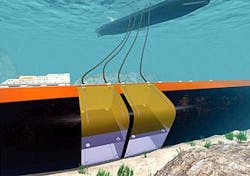

The JLMD system, preinstalled at all four corners of the lateral compartment of a sunken oil tanker (Fig. 1), enables a 70-90% reduction in the pollution, says the company. It can equip any kind of tanker, either single or double hull and of recent or old construction. In addition, the system works in all weather conditions, no matter in what position the ship lies on the seabed.

Operation involves connecting the tanks of the sunken ship to those of the surface support vessel (Fig. 2) with an underwater robot, opening the valves, and letting the water get through the orifices located at the very bottom of the sunken ship's tanks under hydrostatic pressure. The water pressure propels the fuel oil from the tanks up to the surface vessel.

The system can also be used for drawing off polluting liquid cargoes without using motor-driven machinery and without any risk of explosion.