Equipment/Software/Literature

Chock reduces offshore wellhead movement

The Smart Shim, now available in North America, helps reduce excessive wellhead movement caused by wave action on casing conductors.

The firm offers North American customers with a full-service solution—from on-site measurement, design, and finite element analysis, to manufacture and on-site casting of the chocks.

Smart Shim overcomes the potential danger posed by the damaging effects of wave action on conductor tubes with a solution that is tailored on-site for each specific application.

It's designed to achieve the resilience required to hold the conductor firmly in place, prevent damage in the guides, and provide sufficient absorption qualities necessary to avoid further shock damage. Each chock is fitted on-site to the exact required dimensions, eliminating all difficulties related to fitting or staying in place, the company says.

The tailored chock promises to fit, stay in place, and meet wear resistance strength and elasticity requirements needed to provide a long-lasting solution, the firm adds.

Source: Furmanite America Inc., 101 Old Underwood Rd., Bldg. F., La Porte, TX 77571.

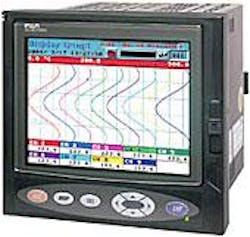

Paperless recorder can display 18 channels of data

This new PHL paperless recorder displays as many as 18 channels of data on a 5.7 in. color liquid crystal display.

A variety of display modes allows users to view data as trends (horizontally or vertically), bar graphs, analog meters, digital-numeric output, totalized output, and event summaries.Switching between display modes can be done quickly and easily with the intuitive eight-key front panel.The adjustable-time screen saver function extends the life of the display and reduces power consumption.

The PHL comes standard with 9 channels, but can be upgraded to 18.Users can record as many as 12 types of thermocouples, 5 types of resistance bulbs, and DC voltage-current input on 1 unit. The PHL can record years of data with the optional 256 MB compact flash card, and the standard 16 MB card is more than adequate, the firm notes.Free PC support software allows users to configure the recorder from a PC, monitor real-time data (using the RS485 communication option), and view historical data stored on the compact flash card. The PHL comes standard with math and totalizing functions.

Source: Total Temperature Instrumentation Inc., Box 1073, Williston, VT 05495-1073.

Miniature pumps for hydrogen fuel cell use

A full line of miniature pumping systems and solutions is available for hydrogen fuel cell (HFC) technologies.

These pumps are designed to meet the stringent requirements of pumping low viscosity hydrocarbon fuel—providing long life, rugged performance, and reliability in low flow, high pressure, high precision metering and dispensing.

HFC technology typically incorporates a fuel processing and delivery subsystem that requires efficient and accurate performance of a pump, motor, and controller in a miniature package. The fuel processor and delivery subsystem converts hydrocarbon fuels into a hydrogen rich gas that is delivered to fuel cell stacks for the generation of electricity (DC).

The firm says its microannular, low flow gear and piston pumps satisfy the requirements inherent to dealing with these hydrogen rich fuels. The pumps' hardened materials provide chemical resistance, while precision machined components help ensure tight tolerances for efficient and accurate operations in stand-alone and vehicular electric power generation systems.

Source: Micropump Inc., Box 8975, Vancouver, WA 98668.

New reservoir-seismic receiver

Here' a new 200 ft long receiver system with the ability to acquire twice as much data in a single pass as the 100 ft unit it replaces.

It effectively cuts in half the time required for data acquisition during borehole (crosswell) seismic surveys, the company says. In addition to reducing acquisition time, the new system uses multiple hydrophones in each of its 20 arrays for higher resolution and a corresponding improvement in data quality. The system is capable of withstanding temperatures as great as 350° F. and pressures of as great as 10,000 psi. The crosswell imaging process becomes more cost-effective with the advent of this device, the firm points out.

The company uses advanced borehole seismic technology to develop reservoir information that it says is more detailed and dependable than surface seismic and well logging can provide; and, therefore more capable of enhancing hydrocarbon recovery from complex formations. Its full slate of globally available reservoir-seismic methodologies and services includes survey design; data acquisition, processing, and interpretation; and incorporating data into clients' models. The company's founders are specialists in crosswell seismic.

Source: Z-Seis Corp., 6209 Windfern, Houston, TX 77040.