Camisea plants, pipelines start up

Ceremonies early last month marked official start-up of the Malvinas gas plant, export pipelines, and Pisco fractionation plant for Peru's Camisea natural gas project with the plant sending out first gas to Lima in one of two new export pipelines.

The project includes gas production from the San Martín field in the lower Urubamba Valley, gas processing at the Malvinas plant about 20 km away, a 715 km (about 444 miles) natural gas pipeline to Lima, and an NGL pipeline (560 km) to a new fractionation plant and marine terminal at Pisco on the Pacific Coast.

Camisea operator is Pluspetrol Perú Corp. SA; Camisea partners are Hunt Oil Co., South Korea's SK Corp., Sonatrach, and Tecpetrol del Perú SAC.

Gas, liquids separation

First gas production began flowing to the 450-MMcfd Malvinas plant in April through flowlines from the San Martín four-wellhead cluster. Cryogenic facilities at the Malvinas plant, named for a nearby village, chill the gas to -73° C., enabling nearly full recovery of the C3+ components (Fig. 1).

Engineering services company Paragon Engineering Services Inc., Houston, told OGJ that design inlet-gas rate for each of the two trains at Malvinas is 220 MMcfd. Paragon also said last month capacity tests were to determine peak throughput, but projections were 450-480 MMcfd for the combined trains (Fig. 2).

The Malvinas gas plant was built near a river to facilitate shipment of major components (Fig. 1; photograph from Paragon Engineering Services Inc., Houston).

Expansion plans being evaluated for Camisea will increase capacity substantially, although final capacity has not been decided, said Paragon.

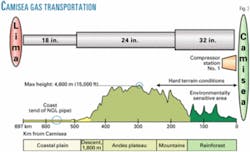

The plant separates and recovers condensate and LPG from the produced gas and sends residue gas to compressor station No. 1, elsewhere in the plant, to begin its trip through the 32, 24, and 18-in. pipeline to Lima (Fig. 3).

The line pipe is API-5L Grade X-65 with wall thicknesses varying according to hydraulics and was supplied by Brazilian mills, according to Paragon.

Without compression, the existing gas line has a capacity of about 300 MMcfd. Increased capacities were considered as part of the original design, through a combination of line looping and additional compression. Ultimate capacity of the pipeline will exceed 1 bcfd, said Paragon.

The gas plant can reinject gas that is not sold, Paragon said, and some has been injected. Normal operation would consist of NGL and natural gas flowing to the pipelines, with gas net of sales being reinjected.

The consortium Transportadora de Gas del Perú (TGP) built the pipelines, which were mechanically completed in July. TGP includes Argentina's Techint (23.4%), Pluspetrol (22.2%), Hunt Oil (22.2%), SK (11.1%), Tecpetrol, Sonatrach (11.1%), Tractebel (8%), and the Peruvian construction company Grana y Montero (2%).

Line pack for the separate 14 and 10-in. NGL line to Pisco is about 300,000 bbl of the extracted raw liquids mix.

Designed for 70,000 b/d, this line moves NGL at an initial production rate of 33,000 b/d in parallel with the gas line for 560 km, as far as the new NGL fractionation plant and export terminal at Pisco on Perú's Pacific Coast.

null

Unique pipe configuration

The Malvinas plant was to have reached full production by late August, along with the fractionation plant and terminal at Pisco, with first vessel loadings to occur in September.

At the Pisco fractionation plant, the raw NGL stream will be separated into propane, butanes, naphtha, and diesel for transport from the Pisco marine terminal. The 55,000 b/d fractionation plant was commissioned in early August (Fig. 4).

At the Pisco fractionation plant, a LPG storage vessel sits near the plant's depropanizer, debutanizer, and topping unit (Fig. 4; photograph from Paragon Engineering Services Inc., Houston).

Paragon told OGJ that, to accelerate start-up at Pisco, it designed generators and heaters for dual fuel—gas and diesel generators and heaters were already operational and running, C3 and C4 were brought in to chill the refrigerated storage tanks and refrigeration system, and diesel was brought in to circulate through the naphtha-diesel stripping system.

Product loading lines at Pisco will carry naphtha (24 in.), diesel (10 in.), propane (20 in.), and butane (20 in.). The land portion is about 1 km; the subsea portion is 3.2 km from shoreline to marine berth.

The propane and butane lines are among industry's first, according to Paragon, in that they employ the unique, thermally efficient "pipe-in-pipe" configuration. Each 20-in. line is insulated and encased in a 24-in. outer line. Subsea operating temperatures will be about –45° C. The 1 km, 20-in. onshore line will be conventionally insulated, while the offshore, 3.2-km line will employ a 20-in. line inside 24-in. line.

The conventional trestle originally proposed generated objections based on high visibility and fear that it would interfere with fishing boat routes, according to Paragon; the trestle was also higher cost.

"The subsea lines resolved all of those issues," said Skip Mick, Paragon project director.

"Pipe-in-pipe technology, with insulation in the annulus between the pipes is used more typically for subsea deepwater offshore production flowlines, where the ambient seawater is cold, to keep the producing fluid warm and flowing.

"We proposed the same technology to keep the –45° C. propane cold when flowing subsea through the warm coastal water."