Technological advances expand potential pay

Technological advancements and rising gas prices came together in the late 1990s to overcome the complexities involved in developing the tight Barnett shale formation in north central Texas.

Slickwater fracture stimulations in the play have had good success in improving hydrocarbon recovery during the last 6 years. But operators are now looking to highly detailed reservoir characterization studies and more refined completion and fracturing practices to further improve recovery efficiencies as infill and expansion drilling continues.

This first in a series of two articles reviews the industry's latest reservoir characterization capability. The concluding part will detail the current completion-stimulation practices.

Given the widespread occurrence of unconventional shale reserves worldwide, the potential impact of these techniques holds promise for accessing these hydrocarbon accumulations.

Play details

Once known largely as a source rock for neighboring formations, the Barnett shale industry now is considered as a world-class, unconventional, blanket gas reservoir. Wells drilled in the play are low-risk, high-reward propositions because of their long-term, steady production.

Led by Devon Energy Corp., formerly Mitchell Energy Corp., Barnett shale exploration and development in the Newark East field, Fort Worth basin, began in the early 1980s, took hold in 1998 rapidly, and continues to this day.

During summer 2003, the play had an average rig count of 50.

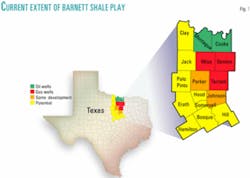

Once focused largely in Denton and Wise counties, Tex. (Fig. 1), the play has grown north into Montague and Cooke counties, and south into Tarrant, Parker, and Johnson counties. Operators also are exploring the potential in Clay, Jack, Palo Pinto, Erath, Hood, Somervell, Hamilton, and Bosque counties.

Fieldwide gas production from more than 1,200 completions exceeds 10 bcf/month, compared to the field's 1.6 bcf/month level during 1995. Newark East field currently is one of Texas' top gas producers and one of the top 20 gas plays in the US.

One challenge operators face is to obtain sufficient well deliverability from the very tight, albeit sometimes naturally fractured shale, which requires hydraulic stimulation before the wells become economic. Although operators have drilled few truly dry holes in the trend, the difficulty has been in establishing sufficient recovery efficiency.

Experimentation with extremely large, low-cost slickwater fracturing treatments in the mid to late 1990s finally unleashed the formation's productive potential while improving play economics. Since then, highly detailed reservoir characterization studies and more refined drilling, completion, and fracturing practices have improved well deliverability and economics.

Horizontal drainholes in selected sweet spots may even take hold as operators try this technique in different regions of the basin.

But the top priority remains improving recovery from existing, infill, and new wells as the play's boundaries continue to expand.

Play geology

The Newark East field reservoir is a stratigraphic trap in the Fort Worth basin. More specifically it is a fault-bound trough in the Mississippian Barnett shale lying at a depth between 7,000 and 9,000 ft and straddling the basin axis.

The shale was deposited on the southwestern flank of the Southern Oklahoma aulacogen. Depositional patterns reflect the generally northwest-southeast trend of the basin axis, although burial patterns reflect the subsequent depositional and structural influence of the larger basin.

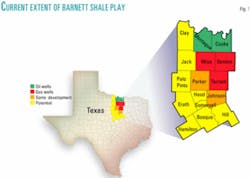

The Barnett shale has upper and lower intervals that are divided sometimes by the Forestburg limestone. Typically, the Barnett shale is assessed as a single unit.

The Lower Barnett interval often is further divided on logs into five distinct members (Fig. 2).

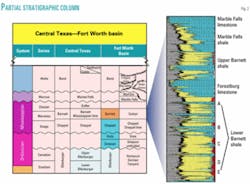

The Barnett shale horizon has an estimated 4,200 sq mile areal extent and a 100-1,000 ft gross formation thickness, which thickens to the northeast (Fig. 3). Although blanket-style in nature, the shale displays local variations in physical and geochemical properties that are important considerations when stimulating and completing individual wells.

The Marble Falls shale-limestone sequence lies above the Barnett shale and forms a good containment ceiling for any hydrocarbons and for hydraulic fractures.

The Viola Simpson limestone or Ellenburger dolomite lies below the Lower Barnett and affects completion and stimulation practices. The Viola Simpson usually provides a reliable reservoir bottom, while the Ellenburger, which is often karsted and porous, typically does not.

The Barnett shale is a black, siliceous source rock with 4-8% organic carbon content, 20-40% illite clay, and no free water. Fine-grained silt, dispersed pyrite, and calcite in the form of concretions, or mineralized fractures, make up the remaining portion of the shale's volume.

Water present in the Barnett shale is bound to either clay minerals or micropores or contained in natural fractures. The illite clays do not react with or destabilize in water, so that the Barnett shale maintains any matrix permeability or porosity present. The matrix permeability, however, is extremely tight, in the micro to nanodarcy range.

The estimated total gas content is only 50-200 scf/ton of rock or 100 bcf/sq mile.

The natural fractures typically are narrow, ranging from 0.02-0.2 mm. These are vertical fractures with little height.

Average matrix porosities are 1-6%.

The play contains various hydrocarbons, including 40° gravity oil, condensate, wet gas, and dry gas (1,000 btu).

Gas occurs as free gas in the matrix, free gas in fractures, or absorbed gas. The gas usually contains less than 2% CO2.

Lessons learned

After more than 5 years of focused experience in the play, operators have found that its productive characteristics vary widely across the basin, reflecting the geologic variability of the formation itself. Some lessons learned include:

- Wells intersecting high natural fracture permeability, determined from production logs, produce the most gas. Initial gas production comes from the fractured and matrix porosity. Then gas desorption from the organic carbon occurs as formation pressure decreases, providing for long-lived production. These wells have outperformed offsets with no open natural fractures by more than three to one in total gas production.

- Slickwater treatments can restimulate wells previously stimulated with older conventional methods. These new treatments connect additional reserves to the wellbore and in some cases initial production after refracing can exceed the original initial production.

- On a per well basis, the Upper Barnett delivers about 20-25% of the production, while the Lower Barnett delivers 75-80%.

- Wells with a Viola bottom, which is not inclined to fracture at the gradients required to fracture the Barnett shale, tend to have fewer problems with water encroachment through faults. Those with an Ellenburger bottom, which can be karsted, can have difficulties with water encroachment and faulting.

- Wells find a Viola bottom more often in the play's northeastern regions, while Ellenburger bottoms occur more often in the play's southwestern regions.

- Pumping oil wells dominate the northern end of the play, while dry gas dominates the south.

- In wells with highly mineralized fracturing in the Barnett shale, operators generally have more difficulty in connecting sufficient shale surface area to the wellbore to obtain desired production levels. These wells usually are found near major fault planes.

- Barnett shale intervals with less clay, or siltier intervals, will fracture more easily. Zones with higher clay content that are stimulated at the same time as siltier intervals usually have a less effective frac.

- Because of the low matrix permeability, the Barnett shale requires large hydraulic fracs for good deliverability. Wells with more surface area connected to wellbore have higher flow rates. The hydraulic fracture usually splinters to form a fairway that has a shape that varies from square to rectangular.

- A sonic-neutron overlay can type Barnett shale hydrocarbons.

Formation evaluation

Productive capacity and economics of the play have improved as growing geologic and reservoir knowledge focuses stimulation and completions practices to fit specific local conditions.

Companies employ various formation evaluation techniques to identify and characterize the precise local nature of the various Barnett members, the natural fracturing, the hydrocarbons present, and the Viola or Ellenburger bottom. They also use production monitoring to determine the effectiveness of stimulation and completion techniques.

A study of more than 300 Barnett shale wells provided the following technical observations and recommendations.

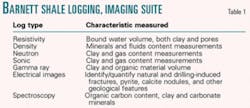

Table 1 shows the fairly typical logging suite used for evaluating Barnett shale wells. The measurements fed into a reservoir lithology model determine overall mineralogy, porosity, and permeability, while the electrical images identify and quantify both natural and drilled fracturing. At press time, work still was underway on means to derive total organic carbon content.

Traditional use of standard log responses provide limited guidance for operators trying to determine if a well will have good or poor producibility. Most Barnett shale wells have a high gamma-ray reading because of the high organic content, resistivities from 10 to 1,000 ohms, density porosity from 0 to 16 porosity units (pu), and a neutron porosity that reads slightly to much higher than the density porosity.

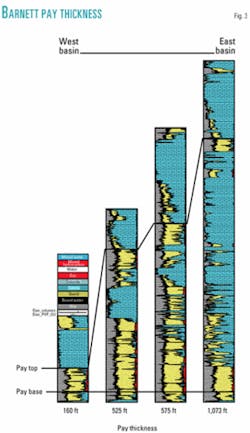

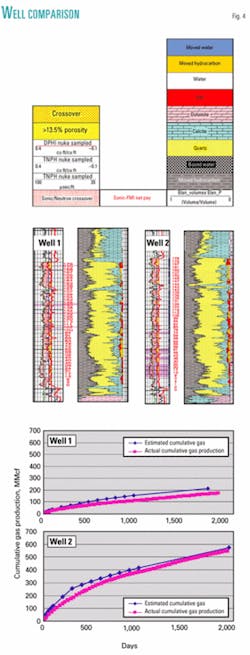

Two offset wells with identical reservoir pay on the logs and completed in exactly the same manner can have two different production histories (Fig. 4). One can produce more than three times as much as the other, as shown for Well 2 in Fig. 4.

Natural fracturing in Well 2, as seen by the magenta-colored bands, aided the production rate and volume recovered.

Including fracture data is one key to successful Barnett shale well evaluation. The Barnett study shows that dense, open, natural fractures contribute to a well's deliverability. While low-aperture or unfractured zones will still flow gas, gas deliverability is at least a magnitude less than from a fractured interval. Thus, the recommended deliverability model uses the lithologic as well as imaging data to handle the fracturing component.

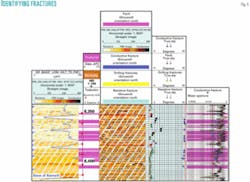

The analysis uses resistivity data to calibrate the electrical images that identify fractures. Experienced geologists use these calibrated images, along with accurate mud resistivity measurements, to distinguish open from healed fractures, as well as fracture apertures (Fig. 5).

The magenta-colored banding seen in Fig. 5, Tracks 2 and 5, indicates locations of open natural fractures, while the fracture dips, Track 4 bright blue tadpoles, are greater than 80° or almost vertical.

The electrical images shown in Tracks 1 and 3 reveal high (white) to low (black) resistivity readings. Local experience guides analysts in setting a fracture aperture cut-off below which fractures will not contribute to enhanced permeability. In Fig. 5, that cut-off is 0.06 mm, as shown by the vertical green line through Track 5.

Analysts use this hands-on evaluation of natural fracturing, which identifies type of aperture (open, healed, or drilling-induced) and strike, to predict a well's natural fracture deliverability. Then the analysis uses this information combined with the lithology model results for forecasting hydrocarbon deliverability.

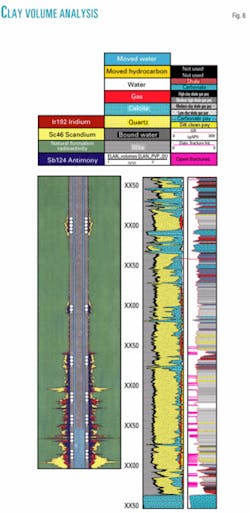

Likewise, the identification of silty zones in the Barnett shale improves overall well evaluation because these zones affect stimulation design and effectiveness. To make these identifications, analysts evaluated lithology to reveal zones with slightly different clay mineral volumes than the norm (Fig. 6).

In Fig. 6, the right-hand track includes magenta-colored banding, indicating natural fracturing, and color-coding for clay volume. The yellow facies indicate the least amount of clay in the reservoir rock. As clay volume increases, the facies shading changes from light gray to dark gray, with the darker shades indicating more clay than the previous lighter shade.

The electrical images that accompany the Fig. 6 log show stratigraphic zones that have greater dips than the surrounding structure, indicating reworked beds. The reworking of these beds has resulted in the reduced clay volumes measured, making them more brittle and susceptible to fracturing.

The electrical images also provide the rock orientation, which helps determine on where to drill the best offsets.

The tracer survey results, Fig. 6 left-hand track, corroborate the fracturing and clay-content data.

The most brittle zones received more frac fluid. Note, that the low clay content zone (yellow facies) within the Upper Barnett did not have open perforations during the stimulation imaged in Fig. 6; thus they show no frac fluid invasion on the tracer survey image.

Stimulation treatment designs that take the more brittle zones into account can improve well deliverability.

Hydrocarbon typing is another important element in Barnett shale well evaluation because the play produces both oil and gas.

Environmentally corrected standard sonic compression, neutron, and density logs accomplish this end. With these corrections, typing can be used for comparative purposes between wells (Fig. 7).

Sonic-neutron overlays from cased or openhole logs are effective. The wide range in hydrocarbon types across the play, from north to south, includes:

- A +40° gravity oil region along the northern basin edge, with sonic-neutron crossovers of 0 to less than 2 pu.

- A condensate and wet-gas region with crossovers from 2 to 5 pu.

- A wet-gas zone, with some condensate, with crossovers from 5 to 10 pu.

- A dry-gas zone, with no condensate, in the southern half of the basin with 10 to 15 pu crossovers.

Finally, because a Barnett shale well's performance depends on connecting a large surface area of reservoir rock to the wellbore, it is critical to identify what will happen to the stimulation when it hits the top or bottom of the Barnett section.

Will a stimulation stay in the desired zone or grow out and connect fluids from nonreservoir rock to the producing system?

Having this knowledge while designing a Barnett stimulation package allows one to design a completion for a specific set of reservoir conditions. A standard suite of well logs will identify the type of rock (carbonate, sand, or shale) lying above and below the Barnett section. The addition of a dipole sonic measurement will allow the calculation of rock properties, including fracturing gradients of the surrounding beds.

This additional information provides insight as to how a hydraulic stimulation will react when it hits the top or bottom of the Barnett.

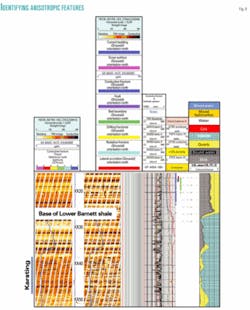

There is one difficulty, however, with fully understanding the beds surrounding a given Barnett shale reservoir. They can have anisotropic features, usually due to natural fractures, karsting, or vugs that standard logs cannot measure.

When these features are water-filled, it is important to avoid them during a stimulation so that the water does not encroach on and overwhelm the low-permeability Barnett production.

Electrical images can identify these features. Fig. 8 demonstrates that porosity and lithology measurements alone do not reveal the karsting present just below the base of the Lower Barnett. The electrical images, Tracks 1 and 3, do reveal the karsting as very dark, almost black, spotting.

Forecasting deliverability

The basic criteria required for evaluating a Barnett shale well include reservoir thickness or pay count, average matrix porosity and permeability, fracture footage, and hydrocarbon type. With an adequate set of logs and the appropriate evaluation methodology, a reliable reservoir model will estimate a Barnett well's production potential (Fig. 4).

There is enough experience in the basin to allow the creation of such models.

The initial completion will have those zones with the best immediate potential for sustained production, while leaving as future recompletion candidates those zones with less potential.

Specific local geologic criteria will determine the optimum completion design for all zones involved.

The author

David Johnston is a lead petrophysicist for Schlumberger Oilfield Services in Dallas. His current focus in on enhancing the Barnett shale reservoir model that he first developed in 1999. At Schlumberger, he has developed a number of special petrophysical applications for improved evaluation of hydrocarbons from both conventional and unconventional sources, including coal seam, copper ore and shales. Johnston holds a BS in engineering science from Trinity University, San Antonio.