Study correlates asphaltene precipitation to reservoir pressure

Modeling of asphaltene precipitation in Bangestan reservoir of Kupal field in southwest Iran estimated the pressure at which asphaltenes precipitate under reservoir conditions. The reservoir-engineering department has plans to inject gas into the reservoir to increase the reservoir pressure above this estimated precipitation pressure.

The modeling technique assumed the precipitated asphaltene was a pure dense phase and divided the heaviest component in the oil into nonprecipitating and precipitating components.

In the study, a set of dummy experimental data tuned an equation-of-state based model that represents the asphaltene as pure component solid. Results of the work show that the selected model could accurately represent the behavior of the fluids in this reservoir.

Bangestan reservoir

The Bangestan reservoir of Kupal field started producing in 1989 under primary depletion. The reservoir has undersaturated oil with the production mechanisms being fluid and rock expansion along with gravity drainage.

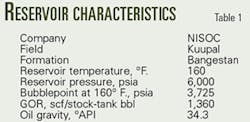

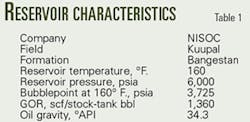

Reservoir performance indicates that the reservoir has no aquifer support. Table 1 summarizes the fluid properties.

According to the experience in National Iranian South Oil Co. (NISOC) fields, asphaltene precipitation becomes a problem when solid precipitation is about 10 wt %. Therefore, when pressure in the Bangestan reservoir of Kupal field approaches the 5,300 psia critical pressure, as determined from the modeling, gas should be injected.

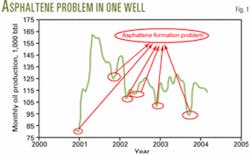

Asphaltene precipitation from the reservoir fluids during oil production is a serious problem because the precipitation plugs the formation (Fig. 1). Currently, NISOC uses improvised mechanical and chemical cleaning methods in wellbores to maintain production, but these methods are time-consuming and expensive.

Generally, asphaltenes tend to remain in solution or in colloidal suspension under reservoir temperature and pressure conditions. They may start to precipitate once the stability of the colloidal suspension is destabilized by changes in temperature or pressure during primary depletion.1 Asphaltenes also have been reported to become unstable as a result of mixing of fluid streams2 as well as from gas injection during improved oil recovery (IOR) operations.3-6

For these reasons, NISOC needed experimental measurements of asphaltene precipitation at reservoir and stock-tank conditions to determine the condition at which the precipitation occurs. The experiments measured asphaltene precipitation at stock-tank conditions and estimated the precipitation from live oil at reservoir conditions.

Asphaltene modeling

The saturates, aromatics, resins, and asphaltenes (SARA) analysis of the stock-tank oil shows that the stock-tank oil has a composition of 26.88 wt % saturates, 67.99 wt % aromatics, 4.47 wt % resins, and 0.66 wt % asphaltenes.

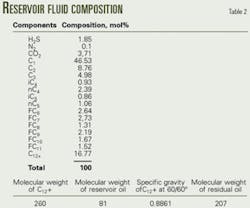

Table 2 summarizes the Bangestan reservoir fluid composition.

The model of the precipitation of the asphaltene phase used a multiphase flash calculation in which fluid phases are described with the Peng-Robinson equation of state and the precipitated solid phase is represented as a pure component. The analysis includes an additional equation to model the fugacity of the asphaltene component in the solid phase. References 7-8 provide the thermodynamic model for the asphaltene component, flash algorithm, and application of the model for the asphaltene formation.

Splitting the heaviest component of the oil into precipitating and nonprecipitating components specifies the asphaltene component. These two components have the same critical properties and acentric factors; however, the precipitating component has higher binary interaction coefficients with light components up to C5.

The following equation calculates the mole fraction of the asphaltene component:

Xsub>asph MWsub>asph = Wsub>asph MWsub>asph

In the equation Xsub>asph. is mole fraction of asphaltene, Wsub>asph. is weight fraction of asphaltene, and MWsub>asph is the molecular weight.

Modeling results

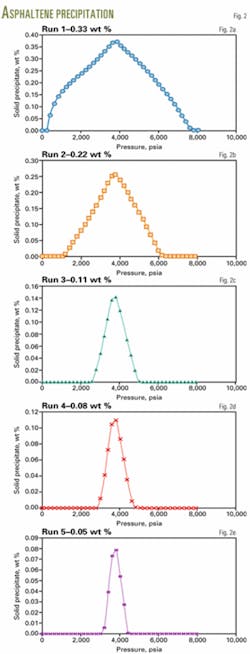

Figs. 2a-2f show the precipitated asphaltene formation behavior as a function of pressure for five different percentages of asphaltene at 160° F. Because no experimental measurement of asphaltene content at reservoir temperature and pressure conditions were available, the analysis used five dummy values of asphaltene content, as follows: 0.33 wt %, 0.22 wt %, 0.11 wt %, 0.08 wt %, and 0.05 wt %

As expected, these figures show that the maximum amount of asphaltene occurs very near the bubblepoint pressure. In addition, because asphaltene problems are occurring at the current 6,000-psi reservoir pressure, it is assumed that reservoir has an asphaltene content greater than 0.22 wt %.

References

1. De Boer, R.B., and Leeriooyer, K., "Screening of Crude oils for Asphalt Precipitation," Paper No. SPE 24987, SPE European Petroleum Conference, Cannes, France, Nov. 16-18, 1992.

2. Catalan, L.L., Jamaluddin, A.K.M., Stephanic, D.W., McNichol, P.A., "Solids Problem at the Ring Border Gas Plant," Journal of Canadian Petroleum Technology, Vol. 37, No. 37 (1998), pp. 48.

3. Koch, H.A." High Pressure Gas Injection is a Success," World Oil, October 1956, p. 260.

4. Thomas, F.B., " Proposed Screening Criteria for Gas Injection Evaluation," Journal of Canadian Petroleum Technology, Vol. 37, 1998, p. 14.

5. Burke, N.E., Hobbs, R.E., and Kashou, S.F., "Measurement and Modeling of Asphaltene Precipitation," JPT, November 1990, pp.1440.

6. Leontartis, K.J., and Mansoori, G.A., " Asphaltene Deposition: A survey of Field Experiences and Research," J. Pet. Sci. Eng., August 1988, p. 229.

7. Nghiem, L.X., Hassam, M.S., Nutakki, R., and George, A.E.D., " Efficient Modeling of Asphaltene Precipitation," Paper No. SPE 26642, SPE 68th Annual Technical Conference and Exhibition, Houston, Oct. 3-6, 1993.

8. Nghiem, L.X., and Coombe, D.A., "Modeling of asphaltene Precipitation During Primary Depletion," Paper No. SPE 36106, Fourth Latin American and Caribbean Petroleum Engineering Conference, Port of Spain, Trinidad and Tobago, Apr. 23-26, 1996.

The author

Mohammad Jamshidnezhad (jamshidnezhad.m @nisoc.com) is a reservoir and production engineer with the National Iran South Oil Co. in Ahwaz, Iran. His research interests include production from carbonate reservoirs and enhanced oil recovery processes. Jamshidnezhad holds a BS from Abadan Institute of Technology and MS from Tehran University, both in chemical engineering, and PhD from Tehran University in petroleum engineering.