Government develops innovative, interactive drilling-waste MIS

Drilling-waste management practices vary throughout the world and are subject to all applicable legal requirements imposed by the relevant regulatory agencies to protect human health and the environment in a particular jurisdiction.

Through funding from the US Department of Energy (DOE), Argonne National Laboratory, in conjunction with ChevronTexaco Corp. and Marathon Oil Corp., developed an innovative, interactive web site to provide technically sound, unbiased information about drilling-waste management options.

Known as the Drilling Waste Management Information System (DWMIS), the web site includes a technology description module to familiarize readers with available options, a regulatory module to summarize existing state and federal regulations concerning drilling-waste management, and an interactive technology identification module to help users identify waste management options available for their region.

The DWMIS can benefit operators by providing easy access to US regulations and waste management options, thus allowing them to choose the option with the most environmental and economic benefits.

The web site also provides unbiased information to countries developing drilling-waste regulations so that the countries will have a basis for allowing operators to use the most economic, environmentally appropriate waste management options, rather than restricting operators to only those options that are commonly used in a particular country.

The DWMIS was opened for public use on June 2, 2004 (http:// web.ead. anl.gov/dwm).

Introduction

The well-drilling process primarily generates two types of wastes: used drilling fluids and drill cuttings.

Drilling fluids (or "muds") are used to aid the drilling process. Muds are circulated through the drill bit to lubricate it and help carry ground-up rock particles (drill cuttings) to the surface, where the muds and cuttings are separated by mechanical means.

Most onshore wells are drilled with either water-based muds (WBMs) or oil-based muds (OBMs), while offshore wells may also use synthetic-based muds (SBMs).

The American Petroleum Institute (API) estimates that about 150 million bbl of drilling waste were generated at US onshore wells in 1995.1 Offshore wells and wells drilled in other countries generate additional volumes of drilling waste.

The oil and gas industry manages drilling muds and cuttings in a variety of ways2 3 that are governed by geographic, climatic, and environmental restrictions, and their resulting costs.

No single set of national standards or guidelines govern drilling-waste management within the US.

Rather, each state has its own set of requirements to protect human health and the environment.

Likewise, there is no single framework of international standards or requirements.

A few authors have attempted to compare the various drilling-waste management standards employed by many countries.4 5

Purpose

Environmentally sound management of drilling waste can represent a significant component of the cost of producing oil and gas.

In theory, many options are available for managing drilling wastes, but not all are appropriate at all locations. Most small oil and gas companies lack the comprehensive information on drilling-waste management needed to make sound waste management decisions.

While much information is available in the literature, it has not been consolidated into a single location, particularly not as an online resource.

Internationally, the picture becomes even more complicated, as countries with established and developing oil and gas industries have either different drilling-waste management requirements in place or, in some cases, no specific requirements at all. Some of the countries do not have historical experience with the drilling-waste management methods allowed in the US, and may prohibit US companies operating in their countries from employing those safe and cost-effective technologies.

The DOE is responsible for ensuring an adequate and affordable supply of energy for the US.

One of DOE's goals is to identify and support new technologies that help in exploring or producing oil and gas at lower cost and with less environmental impact.

Argonne National Laboratory received funding from DOE and has worked with industry partners ChevronTexaco and Marathon Oil to develop an interactive web site that provides comprehensive information on drilling-waste management. This web site is called the Drilling Waste Management Information System (DWMIS).

Operators and government agencies can likewise benefit from a readily available set of technical guidelines for managing drilling wastes.

In the US, state oil and gas agencies have well-defined programs in place that allow operators a variety of options for safely managing oil and gas wastes.

Nevertheless, there are definite environmental and economic advantages to operators selecting the most appropriate waste management option for a given geographic, climatic, and environmental location. The DWMIS provides both large multinational and smaller independent operators easy access to information that can help them select the best location-specific waste management option.

The DWMIS offers even larger potential benefits for operations conducted in other nations, particularly in those countries without well-developed regulations or guidance regarding drilling-waste management.

In some cases, governments outside of the US limit the disposal options available to operators, not because of technical or environmental reasons, but because of unfamiliarity with other environmentally appropriate options.

If officials in those countries had access to unbiased, technically sound information about other waste management options, they might be willing to allow operators to choose more cost-effective environmentally acceptable options.

DWMIS architecture, design

The DWMIS web site is designed to provide tools and information that meet the practical needs of users, including:

- Technical information about drilling-waste management options.

- Access to federal and state regulatory requirements.

- An easy-to-use tool for selecting possible options for an operator's specific situation.

The computer applications that enable the DWMIS user interface include HyperText Markup Language (HTML), ColdFusion, and JavaScript.

HTML, the standard language for web pages, is used to format and present the web site images and text.

ColdFusion is a commercial software package that facilitates connecting databases to web pages through HTML and displays the output. JavaScript enables immediate, dynamic updating of DWMIS based on user input.

The DWMIS home page (Fig. 1) offers access to three main information modules, each of which is described below.

Technology description module

The technology description module provides basic information about practices that are currently employed to manage drilling wastes. The module divides management practices into three sections—waste minimization, recycle and reuse, and disposal.

Users can click on any of the technologies listed on the technology description module's opening page to access separate fact sheets describing each technology and including references for additional information.

Fact sheets are available for the following waste management technologies:

- Separation of muds from cuttings.

- Solidification and stabilization.

- Drilling practices that minimize the generation of wastes.

- Using muds and additives with lower environmental impacts.

- Beneficial reuse of drilling wastes.

- On site burial.

- Land application.

- Bioremediation.

- Discharge to ocean.

- Commercial disposal facilities.

- Slurry injection.

- Disposal in salt caverns.

- Thermal treatment technology.

Regulatory module

The regulatory module identifies and summarizes existing state and federal regulations or guidelines that form the regulatory context for drilling-waste management practices. In the federal section of the opening page, users can click on the US Environmental Protection Agency (EPA), Bureau of Land Management (BLM), or the Minerals Management Service (MMS) to be sent to pages that offer more information about each agency's requirements.

In the state section, users can click on any state on the US map or select a state from a drop-down list to be linked to a state summary page that includes information about the agencies that regulate drilling-waste management in that state. All agency pages contain external links leading to agency web sites and to the specific source text of the relevant drilling-waste management regulations.

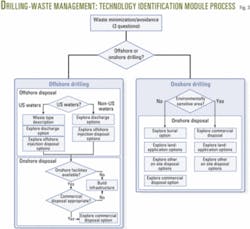

Technology identification module

The interactive technology identification module is a key component of the DWMIS (Fig. 2). Users are asked to answer a series of questions (mostly "yes" or "no" answers). The relevant questions are:

- Does the regulatory agency allow you to use the practice?

- Are the facilities or infrastructure needed for doing the practice available at your site?

- Does your company have any reason not to use the practice?

- Is the practice cost-effective at your location?

The replies to these questions lead users through a decision tree (Fig. 3), resulting in a suggested subset of waste management options that would make the most sense for a given geographical or environmental setting.

The technology identification module does not attempt to tell a company exactly which technology should be employed; rather, it helps to eliminate options that are not appropriate to the user's specific location.

The ultimate decision on managing drilling waste must still be made by the oil and gas company.

Development process

Web site development involved coordination with many different persons and organizations. In particular, preparation of the many state and federal agency pages in the regulatory module involved numerous contacts with agency officials.

The technology description and identification modules were reviewed by other Argonne team members, our industry partners, and ultimately by an external review panel with representatives from major oil companies, independent oil companies, large service companies, state oil and gas agencies, and the EPA. The comments from all of these reviewers are reflected in the final site.

The project team consisted of three separate groups. The authors of this article were responsible for developing the major organization of the web site and its content.

Our industry partners from ChevronTexaco and Marathon assisted us.

The web development team took the content and designed the web site and programmed it to allow for full functionality.

Acknowledgments

Argonne's work on this project is funded by DOE's National Energy Technology Laboratory (NETL), under contract W-31-109-Eng-38. David Alleman is the National Petroleum Technology Office (NPTO) project officer.

Many Argonne staff contributed to developing the DWMIS. The authors of this article prepared the web site content.

We acknowledge the web site design and programming work provided by our colleagues Bob Sullivan, Tom Kotek, and Pam Richmond. Our industry partners included Carole Fleming and Rene Bernier of ChevronTexaco Corp. and Paul Scott of Marathon Oil Corp. Fred Jones, who worked for Marathon at the time the project was started, supported the early phases of the project. Finally, we acknowledge the time and effort put forth by the members of our external review panel, who reviewed a draft version of DWMIS and offered useful comments.

References

1. American Petroleum Institute, "Overview of Exploration and Production Waste Volumes and Waste Management Practices in the United States," prepared by ICF Consulting Group Inc. for the API, May 2000.

2. Veil, J.A., "Drilling Waste Management: Past, Present, and Future," SPE Annual Technical Conference and Exhibition, San Antonio, Sept. 29–Oct. 2, 2002.

3. Veil, J.A., "Costs for Offsite Disposal of Nonhazardous Oil Field Wastes: Salt Caverns versus Other Disposal Methods," prepared for DOE Office of Fossil Energy, April 1997; also published by DOE's National Petroleum Technology Office as DOE/BC/W-31-109-ENG-38-3, DE97008692, September 1997.

4. Jones, F.V., Leuterman, A., and Still, I., "Discharge Practices and Standards for Offshore Operations around the World," presented at the 7th International Petroleum Environmental Conference, Albuquerque, NM, Nov. 7-10, 2000.

5. International Association of Oil and Gas Producers, "Environmental Aspects of the Use and Disposal of Nonaqueous Drilling Fluids Associated with Offshore Oil & Gas Operations," Report No. 342, May 2003.

Based on a presentation in Workshop 16, "Waste Management in the Petroleum Industry," Petroleum Engineering Summer School, Inter-University Center, Dubrovnik, Croatia, June 16-18, 2004.

The authors

John Veil ([email protected]) is the manager of the water policy program in Argonne National Laboratory's Washington office. He analyzes water and waste regulatory, policy, and technology issues relating to the oil and gas and electric power industries for DOE and other nongovernmental clients. Veil has a BA in earth and planetary science from Johns Hopkins University, and two MS degrees (zoology, civil engineering) from the University of Maryland. Before joining Argonne, Veil managed the industrial discharge program for Maryland's department of the environment and had statewide responsibility for industrial water pollution control permitting through the national pollutant discharge elimination system (NPDES), underground injection control (UIC), and oil control programs.

Markus G. Puder (puder@ anl.gov) is an attorney and researcher in the environmental assessment division of Argonne National Laboratory's Washington office. His legal education in the Federal Republic of Germany includes the first and second legal state examinations (German equivalent of JD and multi-jurisdictional bar certification) and a PhD in law from the Ludwig-Maximilians University in Munich. After earning an LLM from the Georgetown University Law Center, Puder became a member of the New York State Bar and the US Supreme Court Bar. He is an adjunct professor of law at the Georgetown University Law Center where he teaches European Union law.

Deborah Elcock (elcock@ anl.gov) is a policy analyst in Argonne's environmental assessment division in Washington. Her education includes an MBA from Dartmouth College and a BA in mathematics from Connecticut College. She has taught courses and conducted workshops on environmental policies and issues nationally and internationally.