Hibernia well sets records

The Hibernia drilling team completed the oil-producing well, B-16 36 (OPA1), off Newfoundland, on Nov. 17, 2003. The well is the longest reach well at this vertical depth in the world. It took 212 days to complete, is more than 30,000 ft measured depth (MD), and almost 13,000 ft true vertical depth, according to ExxonMobil Canada Ltd.

"Drilling this well would have been impossible 10 years ago," said Alex Dodds, president of ExxonMobil Canada. "We originally thought we would have to drill a subsea well and tie it back. Successfully drilling it from the platform cut the total cost by about 50%."

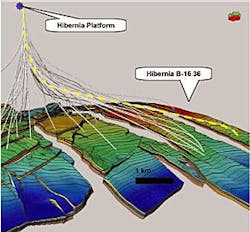

The Hibernia oil field is about 200 miles east-southeast of St. John's, Newf., and Labrador, off the east coast of Canada.

The facility is located in 265 ft of water and consists of a single gravity-based platform with integral drilling, production, processing, gas compression, and crude storage facilities.

The Hibernia offshore oil field is owned jointly by ExxonMobil Canada (33.125%), Chevron Canada Resources Ltd. (26.875%), Petro-Canada (20%), Canada Hibernia Holding Corp. (8.5%), Murphy Oil Corp. (6.5%), and Norsk Hydro Production AS (5%).

null

The field is compartmentalized into a series of blocks separated by faults. In general, each fault block requires one or more of its own producing wells and a gas or water injector well for pressure support.

The A Block uses gas reinjection to maintain block pressure through a well drilled in 2001.

The record-setting OPA1 well is important for Hibernia because it allows for production from the far reaches of the field.

Dodds said the team's goal was "to safely drill a 31,000 ft MD well into the Hibernia A Block. We were looking for a high-rate oil producer capable of sustained rates of about 20,000 bo/d. The well was tested at a rate of 38,000 bo/d."

Numerous records were set on this well:

- Worldwide industry record for rotary steerable equipment days/depth.

- – 9-in. tool: 9.4 days on bottom.

- Offshore Canada industry record for casing setting depth.

- Worldwide industry record for logging-while-drilling (quad combo) equipment run.

- Worldwide industry record for tractor equipment design/depth.

- Offshore Canada industry record for downhole pressure/temperature gauge depth.

- The drill pipe-conveyed MDT (modular dynamic tester) job included record depths for latching the wet connect (26,000 ft) and for successful pressures (30,500 ft) and provided essential data confirming pressure communication with the gas injection well 11,500 ft updip in this large block.

- – 63/4-in. tool: deepest tool run at 29,918 ft.

- – 103/4-in. x 95/8-in. casing at 26,073 ft.

- – 7-in. casing at 30,685 ft.

- – ADN/SONIC/ARC (azimuthal density neutron/sonic/array resistivity neutron) at 30,700 ft.

- – Multiconductor deployment of USIT (ultrasonic imaging tool) log at 17,920 ft.

- – Casing drift and perforating at 30,639 ft.

- – Permanent downhole pressure/ temperature gauge installation at 25,579 ft.

Drilling a well at this depth required sufficient lead time for detailed planning.

The Hibernia team, led by Mark Moyer, ExxonMobil Canada's Eastern Canada drilling manager, drilled and completed seven wells during 2003, with nearly 165,000 ft of section drilled.