SAGD drilling parameters evolve for oil sands

Optimized drilling procedures, incorporating improved directional drilling and ranging systems and slant drilling, allow operators to use steam-assisted gravity drainage (SAGD) wells for recovering bitumen. Future possibilities include alternative wellbore patterns and architectures.

Oil sands are about 10-12% bitumen, 80-85% unconsolidated mineral matrix, and 4-6% water. Although near-surface deposits in Alberta are surface-mined down to about 75 m, bitumen deposits deeper than 75 m require in situ thermal recovery techniques, chiefly SAGD and cyclic steam stimulation (CSS).

Bitumen viscosity is a function of temperature. Canada's Athabasca reservoir sands are about 11° C. with viscosity of 1 million cp and are produced thermally with about 40% or better recovery efficiency.

By comparison, Venezuela's Orinoco extra heavy oil reservoirs are about 53° C. with viscosity of 1,500-3,000 cp and are produced cold with less than 10% recovery efficiency.1

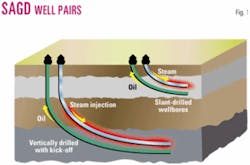

The SAGD process implements parallel horizontal wells fitted with slotted liners or packed screens.

Injected steam from the upper well heats the bitumen, which drains down into the lower well under the influence of gravity.

Conventional steamflooding uses vertical wellbores, and these are sometimes used in conjunction with SAGD well pairs.

null

Early SAGD

In the early 1980s, before the advent of today's horizontal drilling technology, Roger M. Butler at Imperial Oil Ltd. investigated and published drilling techniques that were being used in an "oil mine" project near Urega, Russia. Horizontal wells were drilled into reservoirs from underground tunnels to recover oil.

Alberta Oil Sands Technology and Research Authority (AOSTRA) was formed in 1974 to focus on oil sands research and technology. On May 8, 1984, at an AOSTRA meeting, Butler proposed SAGD drilling in Athabasca oil sands in the Underground Test Facility (UTF) at Fort McMurray, Alta.

The UTF project began in 1987 and involved tunneling into the Devonian limestone beneath the oil sands. Workers brought a small drilling rig into the tunnel and drilled upward into the bitumen.

According to the Alberta Research Council, UTF-based SAGD technology is covered by Canadian and US patents beginning in 1989.

In 1995, two horizontal well pairs, the "D wells," were drilled and completed from the surface in the UTF project and are still producing.

According to Todd Zahacy, a senior research engineer at Edmonton–based C-FER Technologies Inc., "a significant portion of the current expertise, knowledge, and understanding of all aspects of SAGD drilling, completion, production and facilities requirements are the direct result of AOSTRA's UTF project."

AOSTRA was dissolved by action of Bill 7 (ASRA Amendment Act 2000) and replaced by the Alberta Energy Research Institute (AERI) with a new mandate to research and develop technology for all forms of energy. C-FER is a division of AERI.

Current SAGD

Well pairs are drilled horizontally, 4-20 m (usually 5-8 m) apart, using at-bit sensors. Accurate directional drilling is necessary to maintain exact separation and alignment of the well pairs.

The lower well is usually drilled first as a conventional horizontal well because it often has a smaller diameter and is easier to steer. The lower part of the build section of the upper well is drilled with a magnetic ranging system.

The standard system has been Sperry-Sun Drilling Service's magnetic guidance tool (MGT), developed with and licensed from Vector Magnetics LLC. The MGT and wireline are run into the lower well, while the driller steers the upper well to it using magnetic sensors and an MWD system.

Sperry-Sun, a division of Dresser Industries Inc., a Halliburton company, publicizes that well pairs have been drilled over 1,000 m while maintaining a separation of 6-9 m. Each well pair is usually completed in 2 weeks, including surface work.

According to Marlin Polowick at Computalog Drilling Services in Calgary, a newer standard has emerged, using Vector Magnetics rotating magnet ranging system (RMRS; OGJ, Feb. 23, 2004, p. 47). The arrangement of the sensors is reversed in the RMRS; sensors are placed in the first (reference) well, and the second well is drilled with the RMS sub.

SAGD operators in Canada include Canadian Natural Resources Ltd., Deer Creek Energy Ltd., Devon Energy Corp., EnCana Corp., Husky Oil Operations Ltd., Imperial Oil Resources Ltd., Petro-Canada, Shell Canada Ltd., and Suncor Energy Inc.

EnCana Corp. is considered the early adopter in various SAGD technology innovations, including the use of PDC bits.

Polowick told OGJ that among the directional drilling contractors, Halliburton's Sperry-Sun has about 70% of the Canadian SAGD market, followed by Precision Drilling's Computalog with 25%, and the remaining 5% performed by Directional Plus, a division of Cathedral Energy Services Ltd., relatively new to the SAGD market.

Canadian SAGD projects include CNRL's Wolf Lake field, ConocoPhillips/ Total/Devon consortium's Surmont pilot, Deer Creek's Joslyn project, EnCana's Christina Lake and Foster Creek fields (Fig. 1), and PetroCanada's MacKay River project, and Suncor's Firebag project.

In the US, Derek Resources Corp. drilled the first SAGD well pair in its LAK Ranch pilot, Weston County, northeastern Wyoming, from June 24 to July 29, 2000. The wells were drilled by Sperry Sun Drilling Services, reach 1,000 ft TVD, and extend 1,800 ft horizontally into the steeply dipping Newcastle sandstone formation of the Powder River basin.2 The pilot plant was operated in 2001 and 2002, and the project is under further study by the current operator, Ivanhoe Energy (USA) Inc.

SAGD and slant rigs

In order to develop shallow oil sands, operators have a choice of either kicking off the build section immediately with horizontal drilling or using top-drive slant rigs.

Precision Drilling has the largest fleet of slant rigs in Canada (12), and Ensign Drilling Inc. has 6. Precision's super single rigs are convertible to vertical drilling and can accommodate Range 4 drillpipe (45-ft joints).

Precision has a fleet of built-for-purpose SAGD rigs and has built SAGD rigs for Suncor, Petro-Canada, and others.

The rigs are capable of handling big tubulars: surface casing is typically 17-in. diameter, and the build section is drilled at 143/4-in. to accommodate 133/8-in. casing. The lateral section is most often drilled at 105/8-in. to accommodate 95/8-in. casing.

EnCana typically uses a double rig with top-drive to drill a 16-in. hole to set 133/8-in. surface casing, followed by a 121/4-in. build section to set 95/8-in. casing, and an 87/8-in. (222 mm) horizontal section to set 7-in. casing, according to Computalog's Polowick.

Petro-Canada uses slant drilling in the MacKay River SAGD project to reach producing sands at about 150-200 m. The company uses single or super-single rigs, and starts wells from the surface at 45°.

The company has drilled 50 SAGD wells from central drilling pads, after drilling more than 200 vertical delineation wells.

As part of the Phase 1 development of the Joslyn oil project in the Athabasca oil sands northwest of Fort McMurray, Deer Creek drilled a single SAGD well pair using Precision Drilling Corp.'s Rig 130s and ran tubing using a slant service rig (Fig. 2). Deer Creek began steaming on Apr. 10, 2004, and expects production to begin in July.

Low-pressure SAGD

Canadian operators and drilling contractors are on the cutting edge, developing new systems to deal with low-pressure oil sand reservoirs. Amid the industry attention given to oil sands, the Canadian Heavy Oil Association (CHOA) and the Petroleum Society sponsor an annual, 1-day, heavy oil conference in Calgary.

Ken Kisman, at Calgary-based Rangewest Technologies Ltd., discussed low-pressure SAGD issues at this year's conference in March.

He said that planning for artificial lift is "generally prudent" in SAGD projects, and artificial-lift completions require production tubing from the packer to the toe.

Kisman proposed a two-stage artificial lift system that requires large-diameter intermediate casing (133/8 in.). The two-stage pump configuration was designed to improve recovery and to extend pump service life because fluids would be conditioned before reaching the pump.

Kisman suggested that all SAGD wellbores be drilled to accommodate the future option of two-stage systems. He said that the extra drilling costs to accommodate this larger casing were modest: 17% more than 95/8-in. casing and only 3% more than 113/4-in. casing.

Barry Rosof, vice-president and general manager of C-FER, told OGJ that the company's engineers are researching and testing SAGD wellbore design and construction. The company provides consulting, testing, and applied R&D services for individual operators as well as organizing and managing joint industry projects (JIPs).

Zahacy told OGJ that C-FER is involved in a multiphase JIP concerning low-pressure SAGD production. This project was instigated by the Alberta provincial government in order to develop a method of salvaging the disparate interests of "gas-over-bitumen" leaseholders in the Wabiskaw-McMurray area in northern Alberta.

The government had issued separate leases for gas and oil sands, leading to a conflict between the development of oil sands and the production of associated gas in overlying gas caps.

Shallow gas production had caused a pressure drop in the some of the oil sand reservoirs, frustrating efforts of the bitumen leaseholders to develop their leaseholds.

null

Gulf Canada Resources Ltd. (now ConocoPhillips) successfully petitioned the Alberta Energy and Utilities Board (AEUB) to shut-in shallow gas wells on many leases until a solution was developed.

Phase 1 of the low-pressure SAGD JIP began in December 2002 with eight operators participating.

The project included a high-level feasibility assessment, in which development concepts were matched with existing technology and ranked based on economic viability and likelihood of success. It was completed in third-quarter 2003.

Phase 2 began in May 2004 with funding from the Alberta Energy Research Institute three operators: ConocoPhillips, Husky Energy Inc., and Petro-Canada.

The work focuses on the top two ranked technical concepts generated in Phase 1, studying the impact of economics on field development. Zahacy expects this phase to be completed by the end of August 2004.

Between Phases 1 and 2, 10-11 companies participated in a pump-testing JIP, studying the limits of existing technology and addressing two possibilities:

- Use existing pumps and change wellbore shape (alternative wellbore architecture).

- Develop new pumps and use existing wellbores.

Confidentiality agreements block the availability of further details.

Future

Several technologies have been discussed but not field-tested, including research at Petro-Canada on well placement and the possibility of multiple wellbore patterns.3

The Fast-SAGD process, developed by T. Cyr and R. Coates and under research in the petroleum engineering department at the University of Alberta, combines aspects of SAGD and CSS. It has been simulated but not yet field-tested, with patents pending in the US, Canada, and Venezuela.

SAGD drilling depends on the economics of anticipated production. The method is energy intensive and cost of bitumen production is proportional to the cost of natural gas. In his Mar. 29, 2004, keynote address at CHOA's heavy oil conference in Calgary, Eddy Isaacs, managing director of the Alberta Energy Research Institute, said that with natural gas prices at $6.00 (Can.)/Mcf, SAGD operating costs were $9.00 (Can.)/bbl, and with natural gas at $9.00 (Can.)/ Mcf, SAGD operations would be $11.50 (Can.)/bbl.

Continual refinements in the SAGD process will improve recovery efficiencies and justify operations despite the increasing cost of natural gas.

References

1. Total SA presentation, "Sharing experiences in Canada and Venezuela," September 2003. http://www.total.com/ho/fr/library/finance/pdf/pr/field_trip_venezuela/sharing.pdf

2. Grills, T.L., et al., "Case History: Horizontal Well SAGD Technology is Successfully Applied to Produce Oil at LAK Ranch in Newcastle Wyoming," presented at the International Horizontal Well Technology Conference, Calgary, Nov. 4-7, 2002.

3. Chan, M.Y.S., and Fong, J., "Effects of well placement and critical operating conditions on the performance of dual well SAGD well pair in heavy oil reservoir," presented at the Fifth Latin American and Caribbean Petroleum Engineering Conference, Rio de Janeiro, Aug. 30-Sept. 3, 1997.