Equipment/Software/Literature

Credit management software launched

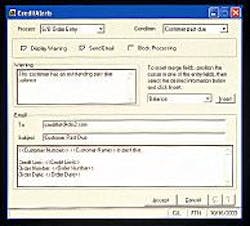

Newly launched CreditAlerts creditmanagement software automatically monitors the credit status of a petroleum distributor's customers and can delay or halt an order from or delivery to a credit risk until the credit issue is resolved.

By identifying good and bad credit risks in the normal course of transaction processing, distributors can focus their efforts on handling credit exceptions rather than analyzing every transaction. It also requires petroleum distributors to resolve the credit issues immediately, rather than delaying them.

CreditAlerts works behind the scenes to introduce a set of credit checks into existing, routine order processing functions. This helps ensure that the credit manager's decisions are applied consistently throughout the company's operational work flow—order entry, dispatch and delivery, and payment processing. It does not change operator work flow or require the distributor to retrain the office staff.

The software uses standard e-mail protocols to offer transaction-blocking (performed automatically by the software) and notification features.

The system can prevent an order or delivery from being processed or send e-mail notification of a pending transaction to help enforce the company's credit policies.

Source: DM2 Software Inc., 7700 NE Greenwood Drive, Suite 200, Vancouver, WA 98662.

New pleated filters help control fugitive emissions

New, application-specific configurations of Mikro-Pleat pleated filter media are available for use in airborne fugitive emissions control.

In either bag or cartridge configurations, the product can be customized for removal of fines, fibers, or other particulates from flows around storage, conveying, or process equipment.

Pleated filters can help improve the capacity and operating efficiency of existing baghouses by increasing the effective filtration media area by two or more times compared with conventional pulse jet bag felt or paper cartridge media, the company says. Features include lower pressure drops, extended filter life, and reduced compressed air usage.

Special filter material and pleat construction give Mikro-Pleat durability. Filters are constructed of a special spunbond nonwoven media. Its density promotes surface filtration of dust and easy release of the collected particulate. The material's strength and durability make possible wide pleats and operation at higher air-to-cloth ratios without plugging, the firm points out.

Available surface treatments include metalized, oil and water-repellent, and Mikrotex PTFE laminate finishes. Where static discharge is a problem, versions with stainless steel or copper ground wires are available.

The one-piece Mikro-Pleat pleated filter with either metal or polypropylene inner core does not require separate support cages. A variety of tube sheet attachment styles is available, permitting clean side and product side installations. One option, the Mikro-Pleat Pop-Top patented collar and venturi design, does not require any special tools or clamps for installation in 5, 5.0625, 5.25, 6, and 6.25-in. diameter tube sheet holes.

A range of cartridge-type Mikro-Pleat filters for virtually all sizes and makes of cartridge collectors in top removal, horizontal, cam-lock, and traditional bottom load filter configurations is offered.

Cartridge-type options include high temperature capability with moisture resistant or fire retardant finishes, Mikrotex PTFE membranes, and conductive or high-efficiency filter media, as well as standard cellulose, cellulose-synthetic blends, and filter felts.

Source: Menardi, One Maxwell Drive, Trenton, SC 29847.

New gaskets seal chemical process piping

New GORE universal pipe gaskets enable chemical process pipe users to standardize their gasket applications across steel, glass-lined steel, and fiberglass reinforced pipe systems wherever a nonmetallic gasket can be used.

Unaffected by aggressive chemicals, these gaskets 1) provide seal reliability, 2) conform to irregular surfaces, and 3) protect flanges.

They are engineered to deliver bolt load retention and achieve creep resistance for reliable sealing of steel piping flanges.

Moreover, they deliver low stress-to-seal in fragile plastic and glass-lined flanges, the company says.

Gaskets deliver sealing reliability across pipe classes. Gaskets operate at temperatures as high as 600° F. and pressures as much as 3,000 psi, thereby allowing their use across virtually all chemical process piping systems. Installation procedures are simple, too, the firm notes.

Source: W.L. Gore & Associates Inc., Box 1488, Elkton, MD 21922-1488.

New high pressure miniature ball valve

This new trunion style miniball valve is effective for shutoff of liquid and gas flow through 10,000 psi. Its trunion style ball design suits it for severe duty uses.

The standard configuration of the three-way ball valve requires a half turn to change the port outlets.

An optional 90° diverter or 180° three-way diverter requires only a quarter turn to change the port outlets. Valves also feature a 316 cold worked stainless steel construction.

Source: High Pressure Equipment Co., Box 8248, Erie, PA 16505.