Equipment/Software/Literature

New lean-burn engine air-fuel ratio controller

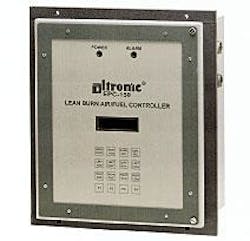

The EPC-150 lean-burn engine air-fuel ratio control shown here is the newest member of an air-fuel ratio control family of products.

It is designed for use on all carbureted lean-burn engines configured for use with a single fuel regulator.

The company says its unit offers reliable, precise, and positive air-fuel ratio control, while maintaining installation and operational simplicity. It also incorporates advanced operating features to address engine conditions specific to lean-burn operation.

Like the EPC-100 air-fuel ratio control for rich-burn stoichiometric engines, the EPC-150 is a closed-loop air-fuel ratio controller designed to adjust fuel delivery precisely to meet and maintain a user-entered exhaust oxygen set point.

The exhaust oxygen level is continuously monitored by a lean-burn oxygen sensor.

During system setup, an exhaust gas analyzer is used to determine the oxygen level at which engine-out emissions are at their lowest, with the corresponding set point entered into the EPC-150 system as the control set point.

Thus, as load and other parameters change on the engine, the EPC-150 will maintain the air-fuel ratio to meet the desired exhaust oxygen level, maintaining in-compliance engine performance.

The controller incorporates a control protocol designed to limit lug conditions whereby a lightly loaded lean-burn engine becomes incapable of generating sufficient turboboost to meet the speed set point established by the governor.

This control approach, which monitors intake air pressure before and after the throttle plate, enables the controller automatically to offset the oxygen set point for richer operation and ultimately increased turboboost pressures.

With the engine operating more smoothly and achieving the necessary rpm, automatic control at the desired oxygen set point is then restored, the firm notes.

As with all other EPC-150 operating parameters, the point at which such an offset would be made, and the value of that offset, is fully adjustable from the front keypad of the control unit or remotely utilizing the integral RS-485 Modbus remote terminal unit communications system.

Source: Altronic Inc., 712 Trumbull Ave., Girard, OH 44420.

New turnkey gas chromatograph system

The new S-PRO 3200 Series of turnkey gas chromatograph (GC) systems performs analysis of sulfur compounds in gaseous and LPG samples.

These new pulsed flame photometric detector (PFPD)-based systems provide low-level (parts per billion) sulfur analysis in an automated, low-maintenance GC system that can even generate its own S-standards using an integrated permeation tube oven.

The permeation oven system provides stable, NIST traceable, multiple low-level sulfur standards for calibration or quality control check samples.

The company says this feature eliminates the costs and errors commonly associated with sulfur standards in gas cylinders.

The sensitivity, stability, and low maintenance features of the PFPD result in a reliable and stable system for sulfur monitoring uses in petrochemical ethylene-propylene operations, the firm says.

Source: O.I. Analytical, Box 9010, College Station, TX 77842-9010.

New titanium heat exchangers

New heat exchangers are made of titanium tubes, with fins in copper or tin-plated copper.

The casing consists of stainless steel.

This firm's new titanium product program is made for serial production, which means that units designed according to the customer's precise requirements—regarding capacity and size—can be supplied in a short time.

Sizes from 0.04 sq m to 7.2 sq m front area, with as many as 12 tube rows are manufactured.

Flows to as high as 40 cu m/s of air can be handled by one heat exchanger.

Source: Coiltech, Flakt Woods AB, SE-614 81 Soderkoping, Sweden.

Free flyer describes flow transmitter

The Series 9200 smart flow transmitter described in a new free flyer is a microprocessor based flow rate indicator-totalizer.

It's designed to receive and process the flow signal from the Series 600-9 inline and 62-9 flow probe thermal mass flowmeters. It is field programmable and is designed for panel, wall, or enclosure mounting.

Source: Thermal Instrument Co., 217 Sterner Mill Rd., Trevose, PA 19053.