Orifice meters provide acceptable wet-gas measurements

Wet-gas metering at wellsites saves capital and operating costs while providing acceptable accuracy unless liquid slugging occurs.

In the process, after an operator completes a new well and produces the well through an orifice meter under wet conditions, the operator should carry out a test with portable equipment at a stable flow rate to determine the water and condensate-gas ratios. If the well only produces water of condensation, the operator does not need further separator tests unless the well starts producing salt water.

In this case, a well's condensate-gas ratios will change very little and will compensate for ratio errors caused by including the vapor equivalent of the condensate in the total well effluent.

Knowing the liquid-gas ratios and the liquid properties, one can then calculate the gas rate from the wet-gas metering with Equation 3 (see equation box) and the total well effluent (TWE) with Equation 9.

Operators do need to test wells periodically to determine the water-gas ratio if the wells produce salt water. Small changes in water-gas ratios have a small effect on the accuracy of wet-gas metering.

Wet-gas metering

Wet-gas metering occurs when liquid water or hydrocarbon condensate flow together with the gas through an orifice plate. This is common for wells without a wellsite separator.

Raw gas produced at a well will always contain a condensed liquid-water phase, which may be quite small. Water-gas ratios of 2-10 ml/std. cu m (0.36-1.78 bbl/MMscf) are common in gas production if a well produces only water of condensation with the gas.

The water-gas ratios can be considerably higher than the previously mentioned ratios if the flow also contains salt water.

If the gas composition contains substantial amounts of propane and heavier hydrocarbons, a liquid hydrocarbon (condensate) phase likely will form at surface pressure and temperature conditions. The condensate-gas ratios depend on the richness of the gas and can vary from very low ratios to more than 90 bbl/MMscf of gas.

For wellsites without a separator to meter gas, the operator has to measure the gas under wet, multiphase conditions. This is a frequent practice in Western Canada.

General correlation

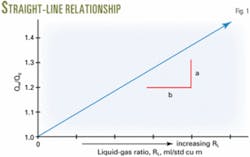

Much research exists on multiphase metering with orifice meters.1-7 The common finding from this research is that a straight-line relationship exists between wet and dry measurements with an orifice meter. The slope of this line is a function of the liquid and gas densities at the meter pressure and temperature.

The ratio of metered wet gas to dry-gas plots as a straight-line relationship with increasing liquid-gas ratio, at constant gas composition and meter pressure and temperature (Fig. 1).

From basic arithmetic of a straight line on Cartesian coordinates, one can obtain Equation 1 from this plot.

Rearranging Equation 1 yields Equation 2.

One can further rearrange Equation 2 to obtain Equation 3, which is used to calculate the gas rate on the basis of wet-gas meter readings and knowledge of the total liquid-gas ratio and the slope factor, Sf.

In 1984, a major oil company developed a general correlation for the slope factor, Sf, from a wet-gas measurement field test on a well in the Whitecourt field in Alberta.

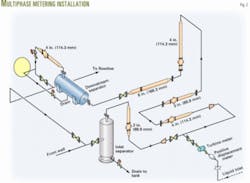

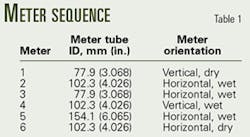

The test included a metering skid constructed to incorporate several orifice meters with different diameters as well as vertical and horizontal orientations. The well in the test produced some condensate with the gas.

Fig. 2 shows the meter arrangements and Fig. 3 shows the equipment hookup. The meter sequence is provided in Table 1.

The test first involved flowing the well through a portable test separator to obtain an initial dry-gas measurement.

In the next step, condensate or water pumped into the gas stream at various rates generated different measured liquid-gas ratios. The flow went through four different orifice meters.

Subsequently for determining the dry-gas measurements, the stream flowed through the wellsite separator.

The company analyzed the different dry gas and wet-gas flows with several wet-gas measurement correlations. It changed orifice-plate sizes in all of the wet meters during the test to obtain data at different beta ratios.

David K. Richardson organized and supervised the tests. His analysis of the results formed part of his research project while enrolled in a master of engineering degree program at the University of Calgary.

Richardson compared the field test measurements with several proposed correlations for wet-gas measurement with orifice meters. He combined the attractive features of two methods and proposed a new correlation for estimating the slope factor, Sf, for wet-gas measurement with an orifice meter (Equation 4).8

One can express the slope factor, S9f, (Equation 4) in more common SI (Le Système International d'Unités) units, as Equation 5.

Lin developed the density ratio term, u.6

One can estimate the liquid density, r1 or rL, based on the water-gas ratio and the condensate-gas ratio at standard and meter temperatures (Equation 6).

A laboratory usually determines the condensate density at 15° C. and 101.325 kPa. One then has to adjust this density to the meter run temperature.

Fresh water has a 999.098 kg/cu m density at 15° C., which also has to be adjusted for temperature. The density adjustments, however, will have only a very minor effect on Sf.

Furthermore, one can restate S9f in common British oil field units, as Equation 7.

Liquid-gas ratio testing

Wet-gas measurement avoids the need for an operator to install a separator at every wellsite. Installation and maintenance costs for three phase, high-pressure separators for sour service are very high.

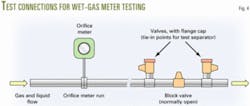

Fig. 4 illustrates the valving arrangement at a wellsite for periodically testing the liquid-gas ratios in wet metering with a portable test separator.

The test connections must always be downstream of the orifice meter run. During such a test, one first meters the fluids under multiphase (wet) conditions before measuring the gas, condensate, and water after it is separated in a portable three-phase separator.

In such tests, operators usually send gas and liquid samples to a commercial laboratory for analysis. Based on the rate measurements and sample analyses, one can verify the previously described slope factor. This is necessary if a well produces salt water because the water-gas ratio may change over time.

If the well produces no salt water with the gas, one can easily use chart methods to estimate the water of condensation.9

Flash calculations with software programs can predict the condensed hydrocarbon phase and gas phase at meter run pressure and temperature. These calculations are based on the reservoir fluid composition determined from a well test or a subsequent wet-gas meter ratio test as described previously.

Without saltwater production, the liquid-gas ratios will remain stable, even with some variation in meter pressure and temperature.

One must only take wet-gas measurements if the well flows without liquid slugging. This is the case if the meter is at the wellsite. If the wet-gas meter is away from the well, liquid slugs are bound to be produced in the flowline that can cause large measurement errors.

Similarly, gas wells on plunger lift will see wide variations in the liquid-gas ratio at the orifice plate and therefore one cannot meter this flow accurately under wet conditions.

Liquid-gas ratios changes

In Alberta, it is required to determine the total well effluent (TWE) whenever a well produces condensate at meter run conditions of pressure and temperature.

Total well effluent is the vapor volume equivalent production at standard conditions of the gas production plus the vapor equivalent of the accompanying condensed hydrocarbon phase. Equation 8 expresses this mathematically.

One can combine Equations 2 and 8 to obtain Equation 9, which is a direct estimate of TWE on the basis of wet meter readings.

Tables 2-4 compare the effects of changing liquid-gas ratios, based on a computer program for orifice metering and incorporating the relationship developed in Equations 5 and 9.

In Tables 2-4, the calculations assume a certain wet-gas flow rate and different liquid-gas ratios. These example calculations are based on a static pressure of 8,000 kPa. At lower pressures, the liquid-gas ratios have lower TWE errors.

In these examples, it is assumed that the static and differential pressures are constant, yielding a constant wet-gas rate, Qw.

Column 2 (Table 2) shows liquid-gas ratios and the gas rate, Qg. as determined with a portable test separator.

Columns 3-6 (Table 2) show the effect of changes in the liquid-gas ratios on the total well effluent rate. This is reflected in the bottom line, in % error. This error would occur in determining TWE if one uses the liquid-gas ratios and gas rate from Column 2 instead of the changed liquid-gas ratios in the subsequent columns.

Thus it can be seen, for example in Column 4 (Table 2), that the water-gas ratio has increased by 20% from Column 2, to 240-ml/std. cu m. This undetected increase in water-gas ratio results in a decrease of 1.13% in the total well effluent rate.

The rate in Column 2 would be the reported rate, which is 1.13% greater than the actual rate as shown in Column 4.

If the well produces condensate with the gas, the condensate-gas ratio will remain fairly constant at the meter run conditions at constant reservoir fluid composition. The installation would require very large changes in meter pressure or temperature, such as more than 20%, to have a noticeable effect on the condensate-gas ratio in most situations.

Even considerable changes in the condensate-gas ratio would not greatly affect the TWE because the condensate will contribute to a greater differential pressure as well as add to the TWE.

These items compensate each other, as shown in Table 3.

If the condensate-gas ratios subsequently change as shown in the Table 3 and the meter readings remain the same, the errors introduced by assuming no changes in condensate production are small.

To generate the comparisons in these tables, one has to assume and hold constant such properties as density and molar mass of the condensate.

Most wet-gas metering involves little or no change in the liquid-gas ratios with time if the reservoir fluid composition remains constant.

The only real exception to this statement occurs when a well produces salt water, in which case the water-gas ratio may change without detection until the next test with a portable test unit.

Table 3 shows the effect of condensate-gas ratio changes on wet metering accuracy, assuming the water-gas ratio stays constant.

One can assume that the values in Column 2 were developed from a wet meter test with a portable separator. The well produces a fairly high condensate-gas ratio along with only condensed water.

Table 4 shows the effect of changing water-gas ratios on metering discrepancies.

If a separator test determines a 6 ml/std cu m water-gas ratio that subsequently increases to 30 ml/std cu m, one would only introduce a 0.75% error in the total well effluent if the calculation used a 6 ml/std. cu m water-gas ratio.

Only at very large water-gas ratios does the effect of the water on wet-gas metering become significant.

Testing the data

Schuster's1 graphs show the effect of water-gas ratios up to 500 bbl/ MMscf on the wet-gas meter at 185 psig and at pressures between 600 and 900 psig.

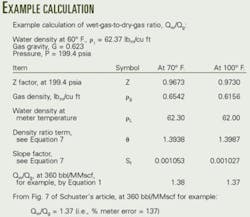

For one set of data, the gas gravity used by Schuster was 0.623, and the meter run pressure was 185 psig. To perform an example calculation for Sf for this set of Schuster's data, one has to make an assumption for the meter run temperature.

The calculations in the example box obtain the slope factor, Sf, and the wet gas to dry-gas ratio at 70° F. and 100° F.

References

1. Schuster, R.A., "Wet-gas can be metered accurately," World Oil, July 1959, pp. 130-42.

2. Murdock, J.W., "Two-Phase Flow Measurement With Orifices," Journal of Basic Engineering, December 1962, pp 419-33.

3. Nangea, A.G., et al., "The Effect of Entrained Liquid on the Measurement of Gas by an Orifice Meter," JPT, June 1965, pp. 657-60.

4. Osborne, W.H., "The Effect of Two Phase Flow on Orifice Measurement," 40th Southwestern Gas Measurement Short Course, Norman, Okla., 1965.

5. Wichert, E., "Multi-Phase Flow Measurement by Orifice Meter," Paper No. SPE 4688, SPE Annual Conference and Exhibition, Dallas, Sept. 30-Oct. 3, 1973.

6. Lin, Z.H., "Two-Phase Flow Measurements with Sharp-Edged Orifices," International Journal of Multiphase Flow, Vol. 8, No. 6, 1982, pp. 683-93.

7. Ting, V.C., "Entrained liquid's effect on orifice meter accuracy studied," Pipe Line & Gas Industry, December 1998, pp. 46-50.

8. Richardson, D.K., Two-Phase Orifice Metering, Thesis, Department of Chemical Engineering, University of Calgary, March 1987.

9. Wichert, G.C., and Wichert, E., "New charts provide accurate estimations for water content of sour natural gas," OGJ, Oct. 27, 2003, pp. 64-66.

The author

Edward Wichert ([email protected]) is an independent consultant and an adjunct professor in the department of chemical and petroleum engineering at the University of Calgary. His research interests are mainly related to sour gas. He has experience in oil and gas operations, drilling, oil and gas production and processing, reservoir engineering, and economic analysis. Wichert holds a BSc in petroleum engineering from the University of Alberta and a ME in chemical engineering from the University of Calgary.