Special Report: CO2 sequestration adds new dimension to oil, gas production

Guntis Moritis

Production Editor

Carbon dioxide sequestration presents both an opportunity and a potential cost for oil and gas producers.

Operating costs will increase if producers have to restrict venting CO2 to the atmosphere. On the other hand, sequestration by injecting CO2 generated by various industrial sources (such as power plants, fertilizer plants, and natural gas plants) into hydrocarbon reservoirs can enhance oil and gas recovery and in addition might earn producers credits for CO2 sequestration or gain some tax relief.

Enhanced oil production (EOR) with CO2 injection is a proven technology for certain types of oils and geologic formations. Also some work indicates that CO2 injection into coalbed methane wells or depleted gas reservoirs has potential for improving natural gas recovery.

Work is ongoing for sequestering CO2 into aquifers. For instance Statoil ASA already is sequestering produced CO2 into an aquifer from the Sleipner West platform off Norway and has plans to reinject produced CO2 into an aquifer in its Snøhvit gas field development in the Barents sea, off Norway (OGJ, Nov. 25, 2002, p. 38).

In the US, the federal Department of Energy (DOE) is providing funding for studies on sequestering CO2 in deep aquifers.

In another form of sequestration, natural gas plants, especially in Canada, have been injecting acid gas composed of hydrogen sulfide (H2S) and CO2 into geologic formations.

Research also is ongoing into disposing of CO2 in the deep ocean, although environmental groups lately have voiced their objections to that possibility for a variety of reasons including the fact that oceans may release the CO2 in only several hundred years compared to the estimated storage for millions of years provided by some geologic formations.

DOE has estimated that CO2 sequestration costs are now in the range of $100-300/tonnes of carbon emissions avoided, but that its goal is to reduce the cost to less than $10/net tonne of carbon emissions avoided by 2015.

Carbon dioxide

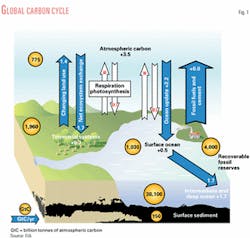

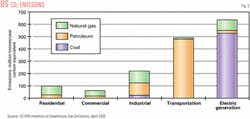

Measurements show that the natural global carbon cycle (Fig. 1) is not removing all of the CO2 being emitted to the atmosphere. This results, therefore, in increased CO2 concentration in the atmosphere over time.

In the carbon cycle, green plants remove or sequester carbon from the atmosphere through photosynthesis. This process extracts CO2 from the air, separating the carbon atom from the oxygen atoms. The oxygen then returns to the atmosphere, while carbon transforms to biomass such as roots, stems, and foliage.

The conversion factor for converting CO2 to carbon is 3.67 tonnes of CO2 equals 1 tonne of carbon. And for going between tonnes and Mscf, the conversion is 19 Mscf of CO2 equals 1 tonne of CO2.

Table 1 from US EPA Inventory of Greenhouse Gas Emissions, April 2002, shows that CO2 is increasing in the atmosphere by 3.2 billion tonnes/year (tpy), which is about half the current human-made (anthropogenic) CO2 emissions. But predictions indicate that this rate of change will substantially increase over time, unless the world takes steps to mitigate CO2 emissions.

The increased CO2 in the atmosphere is believed to contribute to global warming. In an attempt to moderate this temperature change, therefore, some countries are participating in the Kyoto protocol that requires them to limit greenhouse gas emissions.

Even in the US, which has not signed the Kyoto protocol, the government is interested in reducing greenhouse gas emissions. For instance, US Energy Secretary Spencer Abraham recently said "The climate change initiative aims to reduce greenhouse gas intensity in the US by 18% in the next 10 years, while sustaining the economic growth we need to finance investment in new, clean energy technologies."

Three ways to manage excess CO2 in the atmosphere are to:

1.Reduce the use of fossil fuels in combustion engines.

2.Rely less on fossil fuels (coal, oil, and gas) for generating electricity and instead increase the use of nuclear, solar energy, wind power, and or biomass fuels.

3.Capture and securely store (sequester) emitted carbon dioxide in geologic formations or in the deep ocean.

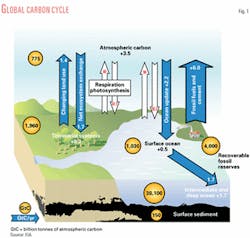

Fig. 2 shows the US CO2 emissions by sector and fuel in 2000.

CO2 emitted by power plants or industrial sources must be captured as a relatively pure gas before it can be sequestered. A DOE report (January 2002) on sequestration said that CO2 is routinely separated and captured as a by-product from industrial processes such as synthetic ammonia production, hydrogen production, and limestone calcination, but that existing capture technologies are not cost-effective.

It has estimated the cost for capturing and processing CO2 from anthropogenic sources is $1-3/Mcf, and that using current available technology for sequestering CO2 emitted from electricity generation plants would increase energy costs by 50% or more.

Its report said that R&D is under way in advanced amine, membrane, and cryogenic separation to reduce costs, and that reconfiguring future power plants to concentrate CO2 in flue gas would dramatically reduce capture costs.

It estimates that CO2 capture represents three-fourths of the total cost of a carbon capture, storage, transport, and sequestration.

Enhanced oil recovery

CO2 sequestration in the form of injecting CO2 for enhancing recovery of oil has been ongoing since the 1970s, especially in the Permian basin of West Texas and Eastern New Mexico. By one estimate, more than 25 million tpy of CO2 are sequestered in US CO2 enhanced oil recovery projects. And these projects, according to OGJ's biennial EOR survey (OGJ, Apr. 15, 2002, p. 43) at yearend 2001, were producing about 190,000 bo/d that otherwise would have remained in the ground (Fig. 3).

CO2 EOR projects are long-lived, with many designed for 10-30 years. Expected additional oil recoveries from these projects are in the order of 7-15% of original oil in place. In recent years, computer simulation of CO2 flood performance has improved and development costs have been reduced as experience with handling the potentially corrosive mixture of CO2 and water has improved.

One unknown in sequestering CO2 in geologic formations is the length of time that the CO2 remains in these formations. Several studies are ongoing to provide answers to this question.

In one study, Advanced Resources International Inc. (ARI), Arlington, Va., is examining field geology and production operations at three commercially productive natural CO2 deposits in the US. It says these sites (McElmo Dome, St. Johns Dome, and Jackson Dome) provide excellent natural analogs for verifying that CO2 can remain in formations for millions of years.

In another study, an international group of organizations with the University of Regina, Saskatchewan, is using such technology as 4D seismic to examine the cap rock integrity to verify that CO2 will remain in the reservoirs in Encana Corp's Weyburn CO2 flood in Saskatchewan.

The Weyburn project uses anthropogenic CO2 supplied in a 204-mile pipeline from the Dakota Gasification Co.'s Buelah, ND, synfuels plant (Fig. 4). Prior to selling the CO2, Dakota Gasification burned the CO2 in its process for converting coal to methane. Shipments of CO2 to Weyburn started in October 2000.

Encana estimates that it will sequester about 20 million tonnes of CO2 to recover about 130 million bbl of additional oil.

Another EOR project in Canada that uses anthropogenic CO2 is Pan West Petroleum Ltd.'s Joffre Viking CO2 flood in Alberta. It receives about 3-4 MMscd of CO2 from the nearby NOVA ethylene-polyethylene plant.

In the US, most CO2 for flooding comes from natural CO2 sources in Colorado (McElmo Dome and Sheep Mountain), New Mexico (Bravo Dome), and Mississippi (Jackson Dome).

But some CO2 for injection also comes from various plant emissions. For instance, Petro Source Carbon Co., Midland, Tex., supplies about 70 MMcfd of CO2 to West Texas CO2 floods through an 82-mile pipeline from the Terrell, Mitchell, and Gray Ranch gas plants in the Val Verde basin of southwest Texas.

Petro Source and Blue Source LLC, Salt Lake City, Utah, also have been involved in selling CO2 sequestration credits, primarily to Ontario Power Generation.

According to Ontario Power, its credit agreement with Blue Source will transfer a maximum of 6 million tonnes of CO2 during 2001-05 and an option for an additional 3 million tonnes CO2 from 2002 to 2004 in the form of CleanAir Canada-registered emission reduction credits (ERCs).

Anadarko Petroleum Corp. has under construction a new pipeline from Bairoil, Wyo., to the Salt Creek CO2 flood to move CO2 being vented from ExxonMobil Corp.'s LaBarge gas processing plant in Wyoming.

LaBarge also supplies CO2 to Chev- ronTexaco Inc.'s Rangley CO2 flood in Colorado and Merit Energy Co.'s CO2 floods near Bairoil.

Another US anthropogenic CO2 source that supplies CO2 to EOR projects is a fertilizer plant in Enid, Okla. Its CO2 goes to Chaparrel Energy's Sho-Vel-Tum flood and Anadarko's Northeast Purdy and Bradley Unit floods.

California has also several oil fields that could benefit from CO2 injection, but an economical source for CO2 is still under study by various companies.

North Sea fields are another potential target for sequestering anthropogenic CO2.

Elsam A/S, Denmark's largest producer of electric power and district heating said that it is investigating if new CO2 capturing technology can make it profitable to inject CO2 into old oil fields and thereby increase significantly oil production from North Sea fields.

Russell Martin of Kinder Morgan, one of the participants in the Elsam CO2 Co. LP study, said preliminary work indicates that Kinder Morgan could build a 400-500 mile pipeline from Denmark to the North Sea and deliver CO2 to these fields for $35/tonne. He said other estimates have placed these costs at a $50/tonne minimum.

Martin said one advantage of CO2 from the Danish power plants is that these plants have already made significant investment in removing other contaminants from the flue gas.

Although Kinder Morgan estimates a lower cost to deliver the CO2 than others, Martin said economic models show that the projects would only be economical if the government lowered royalties or taxes or provided some guaranteed credits to the producing fields.

Kinder Morgan plans envision a level-load pipeline that would supply 2 million tpy of CO2, according to Martin.

Currently Martin said Kinder Morgan has signed a memorandum of understanding with Elsam to study in more detail specific North Sea fields and CO2 sources.

Government relief also may be the key to using more anthropogenic CO2 in US EOR.

Vello Kuuskraa, president of ARI, said that various industry meetings have included discussions on the need for a tax credit such as Section 29 for stimulating the sequestration of CO2 for EOR. The Section 29 tax incentive began in 1980 to encourage unconventional oil and gas domestic production, such as coalbed methane.

Kuuskraa indicated that the industry is looking for about a $5/bbl credit which equals about $10-15/tonne of CO2 sequestered. He estimated that this credit could result in the production of an additional 1 million b/d in the 2012-20 time frame. He also said that the credit would be revenue neutral because various government levels would receive tax benefits from the additional oil produced.

ARI estimates that the global sequestration capacity in depleted oil and gas fields is 923 billion tonnes, which equates to 125 years of current worldwide CO2 emissions from fossil fuel-fired power plants.

Natural gas reservoirs

Studies are also underway to determine the possibility of injecting CO2 injection into depleted gas and gas condensate reservoirs in the US. The work potentially could show that CO2 would recover additional natural gas and gas condensate from these fields. The process would involve re-pressurization to drive residual methane out of the pore space.

A Lawrence Berkeley National Laboratory (LBNL) stimulation shows that using CO2 for enhanced gas recovery in the Rio Vista gas field in California could increase gas recovery by 30% over conventional pressure depletion.

Coalbed seams are another potential place to sequester CO2.

In the process injected CO2 adsorbs onto the matrix of coal seams and remains sequestered, while causing methane to be desorbed and recovered as a free gas.

The Geologic Survey of Alabama with funding from DOE has a research project to determine if CO2 will improve coalbed methane recovery in the Black Warrior basin.

Also with funding from DOE, CONSOL Energy Inc. expects its research to show that a five hole, four-seam pattern could sequester up to 9 bcf of CO2 and eliminate 1.5 bcf of methane emissions while producing 6 bcf from Central Appalachian basin coalbed.

Burlington Resources Inc. in 1995 implemented the first application of CO2-enhanced coalbed methane recovery in its Allison Unit in New Mexico's San Juan basin

The project involved 11 producing wells drilled on 320-acre spacing and four CO2 -injection wells, along with one pressure-monitoring well in the Fruitland formation coals that are about 13-m thick and at a 3,000-ft depth.

ARI, which is doing a DOE-funded analysis of the project, estimates that about 5 bcf of CO2 were injected with a negligible breakthrough until about 4 years into injection.

It said the project was suspended in August 2001 for a study of the long-term effects of enhanced coalbed methane production. It said Burlington Resources' initial evaluation determined that the CO2/meth- ane ratio at the pilot was about 2.9.

Acid-gas injection

Besides EOR, some natural gas plants, especially in Canada, have sequestered in geologic formations low-pressure CO2 with H2S primarily because sulfur recovery from the produced gas has little value. This acid gas is first compressed before being injected into a suitable underground zone, similar to produced water disposal.

Western Canada has the most gas plants that have adopted this compression and injection process for handling acid-gas streams from sour-gas sweetening facilities, but some plants in the US also have installed it. One is GPM Gas Co. LLC's 60-MMscfd Dumas, Tex., gas plant (OGJ, May 22, 2000, p. 58).

In this case, GPM said that it chose the injection scheme when faced with the increasing regulatory requirements and higher operating costs associated with sulfur-recovery units.

The processing plant produces a 450 Mscfd acid-gas stream consisting of 27% H2S, 71.5% CO2, and 1.5% methane.

A 250 hp electric-driven, four-staged horizontally opposed compressor injects the acid-gas stream into a formation at 4,562-4,932 ft.

Aquifer sequestration

Sequestering CO2 in deep saline formations is another possibility. The DOE estimates that deep saline formations in the US (Fig. 5) could potentially store up to 500 billion tonnes of CO2, but this option does not have the benefit of enhancing hydrocarbon production.

It has announced several projects for determining the feasibility of this type of sequestration. One projects with American Electric Power Inc. and Battelle Memorial Institute (BMI) will evaluate potential injection sites in the Ohio River Valley.

ARI estimates that CO2 storage time in aquifers is much shorter, only a few thousand years, compared with potentially millions of years for formations in most enhanced recovery projects.

Aquifer sequestration already occurs in Statoil's North Sea Sleipner West field. The produced gas in the field contains about 10% CO2, and to meet the 2.5% CO2 sales specification, Statoil had to remove much of it. It decided on a process that first uses an amine solvent to absorb the excess CO2 before the CO2 is injected into an aquifer at about a 3,000-ft depth.

Statoil said that it separates and sequesters about 1 million tpy of CO2.

Statoil also plans to reinject produced CO2 at a rate of 700,000 tpy into the 45-75 m thick Tubåsen sandstone at about 2,600 m below the seabed at its Snøhvit development.

Snøhvit involves developing three fields with subsea completions. The produced gas contains about 5-8% CO2 and Statoil plans to separate it out onshore before being piping the CO2 back to a subsea completed injection well.