Outfitting of the Belanak FPSO continues at Batam

Outfitting of the floating, production, storage, and offloading (FPSO) vessel for the Belanak field, offshore Indonesia, continues at a new quayside built by PT McDermott Indonesia on Batam Island, Indonesia. Two ocean-going tugs towed the 175,000-ton hull built in Dalian, China (Fig.1) to Batam during a 3-week voyage in August and September 2003.

ConocoPhillips Indonesia operates the project as a production-sharing contractor to BPMIGAS, the Indonesian government agency responsible for Indonesia's upstream oil and gas business.

Belanak field

ConocoPhillips said, in a press release,"The Belanak field development project forms the cornerstone for the supply of South Natuna Sea Block B gas to Malaysia and Singapore, and the accelerated development of extensive liquid reserves."

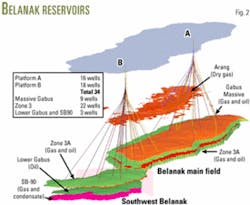

Jeff Smith, ConocoPhillips FPSO Project Manager, in a presentation in Dalian describes the Belanak structure as consisting of two fields, Belanak and Southwest Belanak that cover a 16 km by 4-km area (Fig. 2). He had seven exploration wells were drilled that indicate that the structure has five main reservoirs, as follows:

- Arang at 6,000 ft, a series of dry gas sands, which will be developed a later.

- Gabus Massive at 8,000 ft, a thin oil rim overlain by a large gas cap.

- Gabus Zone 3 at 8,500 ft, a series of oil sands overlain by a large gas cap.

- Lower Gabus at about 9,000 ft, a thick oil sand overlying a water contact.

- SB90 at about 9,200 ft, a series of thin gas condensate rich sands.

Smith said the field, discovered in 1975, was not developed previously because of physical remoteness and limits of the available technology.

ConocoPhillips estimates Belanak contains proved reserves of 142 million boe.

null

It plans to have 34 production wells from two 24-slot wellhead platforms, and has sized the top deck of each platform to support a full platform-based drilling rig capable of drilling to 25,000 ft with support equipment including three mud systems and accommodations for about 110 workers during the drilling.

Drilling commenced in October 2003 with a Nabors self-erecting platform rig, which will drill long, 3,500-ft, horizontal wells in the Gabus Massive and conventional deviated wells in the other reservoirs.

Well completion plans include downhole sand control (sand exclusion liners) in the Gabus Massive and simple oriented perforating in the other reservoirs.

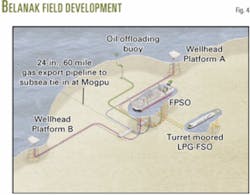

Besides the two wellhead platforms, the Belanak producing facilities include the processing FPSO, export of crude through a loading buoy, export of LPG from an LPG floating storage tanker, and export of gas through existing pipeline systems (Fig. 4).

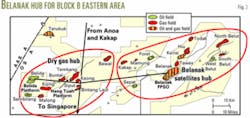

The company intends the FPSO to be a multifield central oil and gas processing hub for the Block B eastern area, which is mainly a wet gas area, and therefore the FPSO has a design capacity that can handle production streams from other fields such as Belanak, Kerisi, Hui, and Belut that are in different stages of development.

The Belanak gas can access two pipeline systems, the West Natuna Transportation System (WNTS) to Singapore and a second line to Duyon that connects into the Malaysian system to Kertah. ConocoPhillips currently sells gas from Block B fields to SembCorp Gas Pty. Ltd. (Sembgas) of Singapore and Petronas of Malaysia under 27-year sales contracts.

The FPSO has a design capacity to store 1 million bbl of oil and to accommodate 25,500 tonnes of topsides modules, including an LPG plant expected to produce 7,800 b/d of butane and 14,700 b/d of propane.

The processing train will handle 100,000 b/d of fluid that can include up to 50,000 bw/d and 4,400 b/d of condensate. The system has a gas handling capacity of 450 billion btu/day and a gas injection capacity of 200 MMscfd.

The FPSO hull is 285 m long, 58 m wide, and has a 26-m depth. Maximum displacement is 255,000 tonnes, and ConocoPhillips said "It is one of the largest FPSO hulls ever constructed." The vessel living quarters accommodate 120.

The FPSO will be spread moored with a 14-leg system in 300-ft of water, about 200 km northeast of Singapore, while the LPG-FSO will be turret-moored about 2.2 km southeast of the FPSO so that it can weathervane freely.

ConocoPhillips plans for the LPG-FSO to have a 78,000 cu m of LPG storage capacity, although it still is in the process of acquiring either a converted or a new build vessel. The offloading will be to a vessel moored alongside LPG-FSO.

The company plans for the FPSO to remain in service for 30 years without the need for dry-docking, and it has specified all mechanical equipment to last for this period with only routine offshore maintenance.

It expects first production through the vessel in the fourth-quarter 2004.

ConocoPhillips with 40% interest in the field operates the project together with its coventurers Inpex Natuna, Ltd. with 35% interest, and Texaco South Natuna Sea Inc. with 25% interest.

FPSO hull construction

ConocoPhillips said it contracted with PT Brown & Root Indonesia and Dresser Kellogg Energy Services (DKES), a subsidiary of Halliburton, to design, engineer, procure, construct, and install the FPSO, including the moorings that will tether the ship to the ocean floor and the flexible risers that will take hydrocarbons to and from the vessel.

Kellogg Brown & Root subcontracted construction of the hull, the module housing all the electrical systems for the hull, and living quarters to Dalian New Ship Heavy Industry

Hull construction commenced in March 2002 and was completed in 18 months.

Paul Warwick, president and general manager of ConocoPhillips Indonesia, said "This is the first time that either ConocoPhillips or Halliburton has built an FPSO hull in China. The Belanak hull is also the first ever FPSO hull of such size and complexity to be built in China."

ConocoPhillips said initial hull design and engineering were performed in Leatherhead, UK, and topsides engineering and procurement from Singapore. PT McDermott Indonesia Ltd had a subcontract for topsides fabrication.