Completion system expanded with new choke

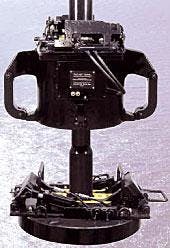

The capability of the InForce Intelligent Completion system has been expended via the new downhole HCM-A hydraulically adjustable choke.

Based on the firm's surface controlled hydraulic sliding sleeve, the HCM-A is a multiposition choke designed for selective zonal control without the need for well intervention.

The choke enables operators to adjust drawdown in each producing interval to prevent cross-flow and balance production so each zone contributes to the well's total production. It also helps reduce or eliminate water from problem zones while maintaining production, the company points out.

In water injection wells, the HCM-A can be used to inject water selectively into each zone independently or allocate flow among all zones simultaneously. By adjusting each valve, water is injected into each zone at optimized rates, thus insuring that the injection front is controlled, and fingering is minimized or eliminated.

The choke combines upgraded features from the HCM sliding sleeve, choke technology from the all-electric InCharge intelligent production regulator, and an eight-position actuator to achieve multi-position choking.

The standard actuator is factory configured to provide open and closed positions plus six choke settings of 3%, 6%, 9%, 12%, 15%, and 20% of total tubing area. These standard choke settings may be reconfigured to provide a customized choking sequence.

The HCM-A hydraulically balanced piston requires two control lines per valve, but by using a third piston chamber port, multiple valves can be configured to share a common close line to reduce the total number of control lines. The application of hydraulic pressure on either side of the piston creates high shifting forces in both directions to overcome additional sources of friction caused by well conditions. To adjust the choke from one position to the next, the valve is cycled to full open and then the pressure is reversed to index to the next choking position.

Source: Baker Oil Tools, Box 3048, Houston, TX 77253.

Process automation controller family expanded

The ControlWave Micro is the newest member of the ControlWave family of process automation controllers.

The company says its new unit breaks the price-performance barrier for small to midsized PLC/RTU products and adds scalability to the ControlWave family. The Micro offers long-term reliability, temperature operation of –40° to +70° C. for remote sites, and low power use for solar uses. In addition, ControlWave has been designed to meet CE and UL Class I, Div. 2 hazardous location requirements.

ControlWave Micro has three serial communication ports and one optional 10/100 Mb ethernet I/P port. Optional built-in spread spectrum radios and worldwide dial-line modems offer integration and communication flexibility. The Micro facilitates communication with other devices through networks such as TCP/IP open modbus, serial modbus, DF1, CIP, HART, and foundation fieldbus.

The ControlWave Designer programming software supports all five IEC 61131-3 programming languages and is enhanced with a library of ACCOL III process control function blocks allowing the use of a single controller for logic, process control functions, measurement, calculations, and data storage. Engineers can also develop their own reusable function blocks. These capabilities are further enhanced with time stamped alarming and historical archive storage within the PLC/RTU itself to provide maximum data integrity. These data are automatically recovered following a communication failure.

The company has standard application written for flow measurement and metering station control for the industry's natural gas segment.

Source: Bristol Babcock Inc., 1100 Buckingham St., Watertown, CT 06795.

Landing string suited for extreme loads

Here's a landing string tool rated at 2 million lb capacity.

The LAST System (Landing And Slipless Technology) promises a high level of safety and repeatability, thus extending the deepwater operating envelope, the company notes.

This new Slipless Technology has been incorporated into various sizes of landing strings including 51/2, 65/8, and 67/8 in., all capable of 2 million lb at superpremium specifications (90% of remaining wall), the firm points out.

Source: Oil & Gas Rental Services Inc., Drawer 2367, Morgan City, LA 70381.