Wet-gas, multiphase metering applications expand

Wet-gas and multiphase metering technologies, developed during the past 15 years, provide compact and accurate measurement systems that can replace conventional gravity-based test separators.

The industry encounters the need to measure wet-gas and multiphase fluid throughout reservoir development, production, processing, and fluid transport to end-users.1

It typically has used conventional gravity-based test separators and flow meters to separate and measure multiphase fluid streams. But in the past 5 years, it has evaluated wet-gas and multiphase measurement system performance by deploying these systems in a broad range of applications.

The field trials of these systems prove that multiphase measurement systems provide a viable method for well testing and measurement solutions that overcome limitations associated with conventional gravity-based test separators.

In additional, these trials have provided a broader understanding of the causes for poor production allocation factors and how multiphase metering technology can improve these allocations.2

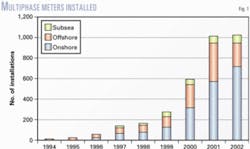

Consequently, the numbers of multiphase meter installations have increased steadily (Fig. 1).

Wet-gas measurement

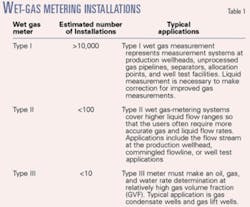

Wet-gas measurements cover a wide range of liquid loading3 and applications (Table 1). Depending on the measurement requirements, wet-gas metering cost and complexity vary considerably. Requirements can vary from an emphasis on gas-phase measurement to gas, liquid, and water measurements.

Wet-gas meter installations differ considerably and depend on the type of wet-gas meter (Table 1).

The demonstrated need for measuring multiphase fluids (gas, oil, and water) at wellheads before commingling production in a common flowline and in subsea transportation lines has established multiphase measurement as an enabling technology for both existing production, retrofits, as well as new reservoir developments.

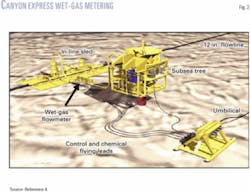

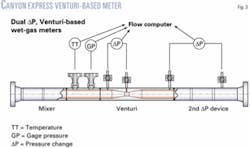

Applications of wet-gas meter such as the Canyon Express in the Gulf of Mexico (Fig. 2)4, where commingling was the only viable option for the development, clearly demonstrate this. Fig. 3 shows the meter installed in the project.

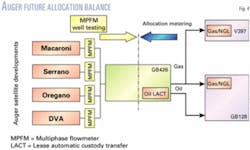

The use of multiphase metering on the Auger platform is another example (Fig. 4).

In this case, multiphase metering improves well-testing accuracy and allocation as well as addressing operational upsets introduced by conventional test separators.5 Fig. 5 shows the meter installed in this application.

The expansion developments of deepwater reservoirs in the Gulf of Mexico are likely to continue the expansion of the industry's need and interest in wet-gas and multiphase metering.

Real-time measurement of gas and liquid flow rate, which can be done by wet-gas and multiphase metering technology, are critical in the management of subsea reservoirs, as a tool for well testing, production optimization, and flow assurance.

The interest in metering wet gas has fostered the development of a number of systems.1 Fig. 6 shows a one-step wet-gas installation; Fig. 7 shows an application in a steamflood in Indonesia.

More vendors are entering the wet-gas and multiphase measurement market. While the cost of deploying multiphase metering systems has declined slightly, the costs still are high enough to limit their application to major projects.

More operators, however, are looking at retrofits and deployment within established projects.

While the development and deployment of multiphase metering systems are growing continuously, a number of factors have inhibited users from taking fuller advantage of the benefits that this technology offers.

The lack of commonly accepted protocols or recommended practices for performance and qualification of multiphase metering systems has forced users and vendors to develop their own standards and definitions. This has resulted in accuracy and performance specifications that vary from vendor to vendor.1

Users and project engineers have had to interpret these specifications and qualify them to obtain performance requirements and compliance for each application.

Fluid properties impact the performance of the multiphase meters, especially the wet-gas meters.

Currently, the industry does not have a reference database to assess the impact of fluid properties on the accuracy and performance of multiphase meters.

Some users have developed their own proprietary database. Others have had to rely upon testing the meters in test loops or fields under simulated conditions.

Field or test-loop testing is expensive and time consuming, especially when the meter selection is for an ongoing project. In addition, often the performance of the new technology is tested by conventional systems with questionable accuracy.

For low liquid content in the gas, such as encountered in many subsea transport lines, processed gas streams, and fiscal metering, the industry encountered a similar situation several years ago and proceeded to initiate joint industry projects6 that have developed correction factors for several devices.

The industry needs a similar program to address higher liquid content and multiphase measurements.

In many applications involving production commingling and allocation, one has to obtain approval to use multiphase or wet-gas meters from appropriate governing authorities and regulatory bodies.

The approval requires having performance data of demonstrated accuracy derived from industry standards, which in this case have not been fully developed.

Industry initiatives

Several industry initiatives are at work to address the above issues. The Committee on Petroleum Measurement of the American Petroleum Institute (API) has formed a task group to look at the development of recommended practices to cover the multiphase and wet-gas meters.7

Also due to the need for guidelines and despite the lack of high-quality field performance records, the Department of Trade and Industry in UK has issued guidelines to assist users in deploying wet-gas metering systems in North Sea operations.

The API8 and the US Minerals Management Service9 (MMS) have also initiated the development of practices to address the need and utility of wet-gas meters for well allocation. API RP-85 addresses many of the issues of uncertainty and meter performance for uncertainty based allocation.

Several operators currently are evaluating a joint industry project to develop a commonly accepted test protocol and provide uncertainty reference data for key fluid mixtures.7

The project has also been submitted to the US Department of Energy (DOE) and MMS for possible cofunding in 2004.

Wet-gas and multiphase metering are growing technologies that are attempting to fill the need for improved production measurements and well allocation that is critical to deepwater developments.

Many onshore and offshore applications have demonstrated that multiphase metering systems can overcome the limitations associated with conventional production measurement systems and a number of industry initiatives are under way to develop commonly accepted practices to improve the qualification of multiphase measurement systems for various applications.

A high-temperature installation of an Agar multiphase flowmeter (MPFM) measures heavy oil in a steam injection field in Indonesia. The produced fluid is about 300° F. The operator has mounted the MPFM on the back of a truck for portability (Fig. 7). Photo from of Agar Corp.

Most of these initiatives are driven by users or operators. It is important that the engineering companies, who in most cases provide the project engineering for deepwater projects, become familiar with the multiphase measurement technologies and become involved in developing commonly accepted practices.

References

1.Mehdizadeh, P., Marrelli, J., and Ting, V.C., "Wet Gas Metering: Trends in Application and Technical Development," Paper No. SPE 77351, SPE Annual Technical Conference and Exhibition, San Antonio, Sept. 29-Oct. 2, 2002.

2.Theuvney, B.C., and Mehdizadeh, P., "Multiphase Flowmeter Application for Well and Fiscal Allocation," Paper No. SPE 76766, SPE Western Regional /AAPG Pacific Section Joint Meeting, Anchorage, Alas., May 20-22, 2002.

3.Mehdizadeh, P., Marrelli, J., and Ting, V.C., "Meter designs provide wet-gas measurement alternatives," OGJ, Mar. 24, 2003, pp. 53-57.

4.Webb, R.A., "Subsea Wet Gas Meters and Their Unique Allocation Issues," Third Annual Multiphase Measurement Users Roundtable, Houston, May 7, 2003.

5.Williamson, K., "Multiphase Metering of Deepwater Flowlines–Auger Experience," Third Annual Multiphase Measurement Users Roundtable, Houston, May 7, 2003.

6.Britton, C., et al., "Experimental Wet Gas Data For A Herschel Style Venturi," Fifth International Symposium on Fluid Flow Measurement, Washington DC, April, 2002.

7.Mehdizadeh, P., "Status of MP and WG Metering," Third Annual Multiphase Measurement Users Roundtable, Houston, May 7, 2003.

8.API Recommended Practice RP-85, "Use of Subsea Wet-Gas Flowmeters in Allocation Measurement System," Aug. 28, 2002.

9.Primeaux, E., "Allocation Procedures Utilizing Wet Gas and Multiphase Meters," Third Annual Multiphase Users Roundtable, Houston, May 7, 2003.

The author

Parviz Mehdizadeh (p.mehdi- [email protected]) is a consultant with Production Technology Inc. He previously worked for Conoco Inc. Mehdizadeh holds a BS and MS in physics and PhD in chemical engineering and materials science from University of Oklahoma. He is a member of SPE well operations committee and is currently working with the API committee on petroleum measurements