Study compares COS-removal processes

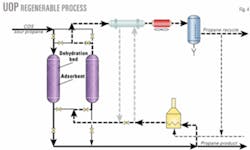

A recent study evaluated the different treating processes that remove carbonyl sulfide (COS) from propane streams. The study grouped seven different process types into nonregenerable, regenerable, and hybrid system categories and outlined the advantages, disadvantages, and cost basis for each.

Because millions of gallons of propane trade commercially every day, a detailed understanding of the allowable limits for COS is important to suppliers and users of propane. COS is a propane contaminant; removal systems are necessary when COS concentrations exceed allowable limits.

The US National Institute of Standards and Technology is conducting GPA Project 982 to help establish these limits. GPA Project 991 examines technological and commercial merits of existing sorbent technologies that can reduce the COS concentrations in propane.

The study is a result of Pearl Development Co.'s participation in Project 991.

COS formation

The formation of COS is governed principally by the reversible hydrolysis reaction and equilibrium conditions present:

COS + H2O <—> H2S + CO2

Because most natural gas is saturated with water, COS does not usually occur naturally in reservoir production.1 COS can form, however, by the conversion of H2S and CO2 in the absence of water, for example, in molecular sieve dehydration beds.

COS that forms in molecular sieve beds upstream of NGL-recovery plants tends to concentrate in the propane product stream.

A relatively small volume of COS can combine with water to form H2S if suitable equilibrium conditions exist.

Because COS does not directly affect a copper strip test, its presence is often not investigated in propane sales. If water is present in the propane transport system with a small volume of COS, however, the received product could fail a propane copper strip test due to hydrolysis of COS to H2S and CO2.

COS formation is catalyzed in dehydration units that use molecular sieves such as 4A and 5A grades. Certain molecular sieve crystals accelerate the formation of COS due to the:

- Large surface area of zeolite crystals available for catalysis.

- Basicity of the crystal structure.1

- Concentration of H2S and CO2, and a lack of H2O, within the sieve pores as these materials are adsorbed simultaneously.

Facility design

Technologies are available that remove COS from liquid propane streams, including amine treatment and sorbent treatment. When the only contaminate in the liquid propane stream is COS, sorbent treatment may be the more economical process.

We chose two basic facility designs for this study to represent a significant portion of all applications: 50,000 gpd and 300,000 gpd.

Each design uses a propane inlet stream at 400 psig and 80° F. The propane stream has a water concentration of 10 ppm (wt) and was previously treated for H2S and CO2 removal as necessary to meet an HD-5 propane specification.

We assumed that the treating facility did not have a fuel gas stream and that the propane stream would be used for regeneration and fuel gas, if required. We studied various cases to understand how this approach affects the economics.

Technology options

Our study excludes amine-based technologies for COS removal. We did not analyze identical technologies from different vendors because the study's intent was to investigate benefits and drawbacks of various technologies, not to determine the best supply cost from a particular vendor.

Vendors often have different technologies that are similar to the ones in this study; they should be considered for an optimum design on a case-by-case basis. We analyzed seven technologies categorized as nonregenerable, regenerable, and hybrid processes.

Nonregenerable processes

In each of these three cases, the media were arranged in a "lead-lag" bed arrangement to ensure breakthrough and full media use before switching.

These processes will coload with other sulfur species (H2S, CS2, etc.); therefore, downstream product dryers can improve bed life and act as a guard against sulfur breakthrough during dehydration bed switching.

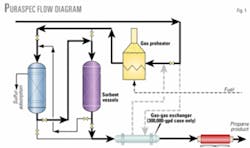

- Type I: One-stage direct adsorption with inlet preheating. Synetix's Puraspec 5030 is the basis of comparison for this technology (Fig. 1). Puraspec 5030 is a nonregenerable product, a proprietary blend of copper and zinc oxides that chemically react with sulfur to form stable metal sulfides.

Advantages for this type of process are that metal sulfide formation in the sorbent is a nonreversible reaction, which ensures a high-purity treated product.

Also, the catalyst has a high sulfur loading, 25 wt %, and spent media are recycled for metal recovery or disposed as nonhazardous waste.

The disadvantages are that the process is best suited for inlet temperatures greater than approximately 160° F. This material is therefore best suited for applications in which the operator can reduce or eliminate inlet preheat costs.

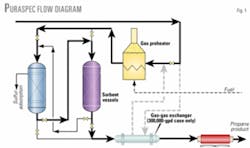

- Type II: One-stage direct adsorption (no preheat), low sulfur-loading adsorbent. Sud Chemie AG's G-132D is the basis of comparison for this technology. G-132D is a nonregenerable product that is a blend of mixed metal oxides, including copper and zinc oxides, in an alumina binder. The product reacts with a range of sulfur species to form metal sulfides.

Fig. 2 shows a process flow diagram for this technology.

The advantages of Type II processes are that formation of metal sulfide in the sorbent is a nonreversible reaction, which ensures a high-purity treated product. The processes require minimal capital equipment.

The G-132D process has been developed as a finishing product to ensure high-purity propane upstream of a polymerization plant.

The disadvantage is that the process can only achieve a low sulfur loading of 5 wt %.

- Type III: One-stage direct adsorption (no preheat), high sulfur-loading adsorbent. BASF AG's R3-12 is the basis of comparison for this technology.

The BASF process uses a nonregenerable adsorbent consisting of a blend of copper, zinc, and alumina oxides in tablet form. The product reacts with a range of sulfur species, including COS, via chemisorption to form metal sulfides.

Type III advantages are that increasing sorbent replacement frequency allows the process to handle 33% higher flow rates and a higher sulfur loading (20 wt %) than Type II processes.

R3-12 is used extensively for propane and propylene purification when removal of COS and other contaminants is required upstream of polymerization plants.

The disadvantages are that new sorbent requires a dry-out down to 6-8 wt % water before going online.

Regenerable processes

For these processes, a slipstream of treated propane serves as the regeneration gas. How the sulfur-rich regeneration stream is treated downstream of the process has a significant effect on the economics of each methodology.

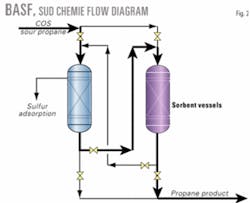

- Type IV: Two-stage hydrolysis and adsorption onto a 5A molecular sieve. Sud Chemie's C53-2-01 hydrogenation catalyst and Zeochem AG's Z5-01 molecular sieve are the basis of comparison for this technology (Fig. 3).

Sud Chemie's C53-2-01 is a platinum-on-alumina hydrogenation catalyst that converts COS to H2S and CO2. Water is injected at a minimum of five times the stoichiometric requirement to enhance the hydrolysis reaction. Catalyst degradation in this application can result from small solid particles blocking active sites; sufficient de-activation of the catalyst will necessitate its replacement after 5 years or more.

Zeochem 5A Z5-01 is a standard 5A-grade molecular sieve. This sieve cost-effectively removes H2S, CO2, and excess water from the treated stream via adsorption.

The 5A molecular sieve, unlike 4A or 13X molecular sieves, does not facilitate rapid reformation of COS and is able to reach the 2-ppm (wt) COS specification at given regeneration frequencies.

If lower COS specifications are required, a low-sodium 5A molecular sieve can minimize COS formation due to the conversion of H2S and CO2 back to COS and H2O.

The advantages of regenerable processes are that they can handle additional sulfur load by increasing regeneration frequencies. An additional hydrolysis bed and new dehydration sorbent can easily achieve this in a plant with existing product dehydration.

A disadvantage is that for a higher-purity product, a low-sodium molecular sieve must replace the dehydration sorbent.

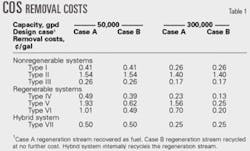

- Type V: One-stage regenerable adsorption with water guard bed. UOP LLC's 3A-DG molecular sieve and RK-29II adsorbent are the basis of comparison for this technology.

The UOP 3A-DG molecular sieve is used for dehydration. This material will not absorb H2S because it is too large for the pore size. RK-29-II is an A-type crystalline zeolite with a nominal pore size (5 Å).

It removes H2S, methyl mercaptans, and COS. In this case, because little water is expected, the 3A-DG sieve can be removed or used as a guard bed.

UOP has recently recommended Cosmin 105A, a derivative of 3A molecular sieve, in place of the 3A-DG to minimize COS production during dehydration. Cosmin 105A reduces COS production to less than 5% of levels experienced with typical 4A molecular sieves.

Also, UOP recommends RK-29 for high H2S and CO2 concentrations or when methyl and ethyl mercaptans are present. When ethyl and methyl mercaptan removal is required in addition to water, COS, H2S, and CO2, the operator can use a compound bed of Cosmin 105A, RK-29-II, and RK-29. Sorbent replacement should occur in 3 years or more.

The advantages of Type V processes are that they can handle additional sulfur load by increasing regeneration frequency and the dehydration and COS-removal sorbents can occupy one vessel.

The disadvantages are that a dehydration guard bed increases regeneration requirements and olefins and diolefins present at elevated temperatures degrade sorbent performance. Normal treating temperatures are 60-120° F. Also, whereas other sulfur contaminants will coload with COS, the COS will be the first compound to break through for Type V processes.

Fig. 4 shows a process flow diagram for a typical Type V process.

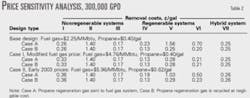

- Type VI: One-stage regenerable adsorption, reduced regeneration requirements. Alcoa Inc.'s Selexsorb COS adsorbent is the basis of comparison for this technology.

Selexsorb COS selectively removes CO2, COS, H2S, and CS2 via adsorption to concentrations low enough to protect polymerization catalyst beds from COS degradation.2

The advantages are that the process can handle additional sulfur load by increasing regeneration frequency.

The disadvantages are that the sorbent's performance degrades at temperatures greater than 120° F.

Also, whereas other sulfur contaminants will coload with COS, the COS will be the first compound to break through.

Fig. 5 shows the Alcoa Selexsorb COS process.

Hybrid systems

Type VII is a three-stage hydrolysis process that uses nonregenerable adsorption and 4A molecular sieve dehydration.

Synetix's Puraspec 5312 hydrolysis catalyst and Puraspec 5208 sulfur adsorbent, combined with Zeochem's Z4-01 molecular sieve, is the basis of comparison for this technology.

Puraspec 5312 is an activated alumina hydrolysis catalyst that converts COS to H2S and CO2. Trace metal contamination blocks the active sites, which degrades the catalyst; it must be replaced every 5 years.

Puraspec 5038 is a nonregenerable adsorbent that uses a combination of copper and zinc metal oxides to remove sulfur from the propane stream as stable metal sulfides. Puraspec 5038, although similar to Puraspec 5030, contains a higher concentration of copper oxide and some proprietary promoters. This makes the adsorbent more suited to sulfur removal at ambient temperatures.

A hydrolysis bed upstream of the ambient temperature bed ensures a more efficient operation and a lower concentration of COS in the propane product stream.

The operator can recycle the spent media for copper recovery or disposed of it as nonhazardous waste.

Zeochem Z4-01 is a standard 4A-grade molecular sieve commonly used for dehydration. With a sulfur adsorbent upstream, the 4A sieve removes excess H2O and CO2, ensuring that the propane product will meet sales specifications.

The advantage of a hybrid system is that it can handle additional sulfur by increasing regeneration frequency.

Also, the regeneration gas is recycled, thus ensuring economic operation in all applications. It has lower long-term operating costs compared to other processes.

The disadvantages are high capital equipment costs due to system complexity and the sulfur adsorbent bed must be replaced every 6 months, or more often at higher sulfur loads.

Fig. 6 shows the hybrid system process flow diagram.

Economic analysis

How the regeneration stream is handled after processing, or what plant options exist for recycling, will affect COS treating costs. To understand these effects, we used two different designs.

Design Case A assumes that regeneration gas is recycled as fuel and, therefore, recovered at the cost of fuel.

Design Case B assumes that regeneration gas is recycled to a treatment plant, such as an existing amine system.

No propane is lost and the recycle treatment costs are assumed to be negligible.

The economics, therefore, represent two extremes—Case A is the most expensive and Case B is the least expensive.

Fig. 7 shows the arrangements of Cases A and B.

We first determined the cost of major equipment, then multiplied these costs by an installation factor of 3.5 to estimate the total installed costs. Installation factors3 are widely used for developing budget estimates, such as feasibility studies like this project.

We estimated equipment costs associated with the project using in-house tools. These tools are sufficiently accurate and we adjust them periodically to reflect actual quotations we receive for similar equipment during recent projects.

The economic analysis reflects a pretax net present value at a 10% discount rate over a 10-year operating period.

GPA Project 991 guidelines assume a propane price of $0.40/gal and a fuel gas price of $2.25/MMbtu. We made additional assumptions to account for freight, spent media recycle and disposal fees, electricity, water, labor rates, and operating overheads.

Table 1 shows the COS removal costs for the two different cases.

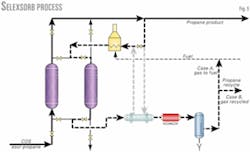

Price sensitivity

The price of natural gas and propane has changed substantially since we performed the initial study in September 2000.

The higher prices, combined with variations in specific plant designs and the availability of economic fuel or regeneration gas recycling, change the economics significantly. An operating company should therefore consider all technologies before making the final selection.

We prepared two new pricing conditions in a sensitivity review.

Case I investigates a higher price of fuel gas to represent an equivalent value for propane using the base price of $0.40/gal.

This shows how the economic model was structured to illustrate maximum and minimum processing fees based on design Cases A and B.

In Case I, because the fuel gas and liquid propane have equal value, COS-removal costs are the same whether the propane is sold as a liquid product or vaporized as fuel.

Case II investigates process economics given early 2003 natural gas and propane prices. The results vary depending on the technology used.

Systems without fuel gas use show no change and systems burning fuel gas have prices as much as 40% higher depending on regeneration gas exchanger's design.

The most striking conclusion is for regenerable systems in which the regeneration gas can be recovered as fuel. In this case, variations in recent market prices and the sale of propane into a facility fuel stream offsets the processing costs and creates savings of up to 34%.

Table 2 shows results of the price sensitivity analysis.

Findings

The simple designs of nonregenerable processes are superior to other options for standalone propane treating facilities that remove approximately 30 ppm (wt) of COS in the 50,000-300,000 gpd flow ranges.

The disparity in loading capabilities of the three products shown is a concern, as well as bed size and sorbent use.

GPA is currently conducting bench-scale laboratory testing of these products to determine consistent sulfur loading capability for each.

The Type III product is the low-cost option; however, we have excluded drying costs that may be required, which will reduce the cost difference between Type III and Type I processes.

Type I is more competitive for treating a hot propane stream. For operating scenarios in which ambient temperature, low-pressure propane must be treated, however, Type I processes may not be desirable.

Regenerable systems are more competitive and eventually more effective than nonregenerable processes if any of four independent variables change:

- Plant inlet flow.

- Amount or number of sulfur-based contaminants.

- Water contaminants in the inlet stream.

- The availability of low-cost regeneration stream recovery via recycle, fuel gas, or other options.

The hydrolysis catalyst and low-sodium 5A option in Type IV processes and the direct adsorption option in Type VI processes are attractive in the lower flow rate, low-contamination scenarios.

All three regenerable options are attractive options in large scale, high-contamination facilities in which a regeneration stream is available or can be recovered at effectively zero additional cost.

The hybrid process that includes hydrolysis, nonregenerable adsorption, and molecular sieve dehydration has clear advantages compared to regenerable processes for cases in which regeneration gas cannot be recycled efficiently.

Type VII processes become more attractive at higher costs for treating or utilizing the regeneration stream for other purposes. This is due solely to internal recycle of regeneration gas and early removal of the sulfur-containing compounds, which keeps product sulfur separated from the molecular sieve beds.

We recommend a full sulfur speciation, water content, and CO2 content analysis for the propane stream before one attempts to specify a specific technology. This information will help vendors determine an optimal course of action with the variety of products available.

It will also ensure a sample analysis that shows the amounts, if any, of ethylene, propylene, or other olefin compounds. These compounds can sometimes reduce the effectiveness and life of the catalysts and sorbents. Environmental poisons such as benzene, arsenic, and mercury can also attach to the sorbent material, which increases handling and disposal costs.

References

1. Trent, R., "The Practical Application of Special Molecular Sieves to Minimize the Formation of Carbonyl Sulfide during Natural Gas Dehydration," presented to the Laurence Reid Gas Conditioning Conference, Mar. 3, 1993, Norman, Okla.

2. Smith, David L., "Applications for Selective Adsorbents in Polymer Production Processes," Alcoa Technical Bulletin, Alcoa Inc., January 1998, pp. 1-8.

3. Lang, Hans J., "Simplified Approach to Preliminary Cost Estimates," Chemical Engineering, June 1948, pp. 112-13.

Based on a presentation to the 82nd Annual GPA Convention, Mar. 9-12, 2003, San Antonio.

The authors

Stuart Watson is a mechanical engineer-project coordinator for Pearl Development Co., Bailey, Colo. He previously worked for Transfield Worley Ltd. Watson holds a BS (1995) in mechanical engineering from Curtin University, Perth, Australia.

Russ Kimmitt is a process engineer-project coordinator for Pearl Development Co. He previously worked for Amoco Canada Petroleum Co. (now BP Canada Energy Co.) and Chevron Canada Resources Ltd. (now EnerPro Midstream Inc.). He holds a BSc (1997) in chemical engineering from the University of Alberta, Edmonton. He is a member of the Association of Professional Engineers, Geologists & Geophysicists of Alberta and is a licensed PE in Colorado.

R. Bret Rhinesmith is president of Pearl Development Co., founded in 1993, He previously worked for Mark West Hydrocarbon Inc., Stearns-Roger Division of Raytheon Engineers & Constructors Inc., and Conoco Inc. He holds a BS in chemical and petroleum refining engineering from the Colorado School of Mines. Rhinesmith is a member of GPSA, AIChE, SPE, NSPE, and other industry associations, and is a licensed PE in Colorado and Wyoming.