Stimulation tube restores production in Gulf of Mexico gas well

An oxidizer-based tool successfully restored gas production from a Unocal Corp. well in Gulf of Mexico Brazos Block A105, according to the service provider Expro International Group PLC (Expro). It said the job increased production from no production to a stable 4 MMscfd flow rate, with rates as high as 5 MMscfd observed.

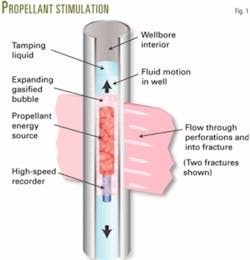

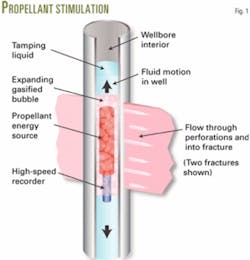

Expro's StimTube process for reservoir stimulation detonates a potassium perchlorate oxidizer that can generate large volumes of high-pressure gas, as much as 20,000 psi at the reservoir face (Fig. 1).

It said these high-pressure gas pulses effectively break down perforations, initiate fractures, and eliminate near wellbore damage.

Tool application

The technology uses the same propellant as the Stimgun (OGJ, Sept. 25, 2000, p. 64) but the StimTube has a smaller OD and is not combined with perforating guns, thereby allowing it to enter smaller ID tubulars.

Expro said the tool can be run through tubing or on slickline to stimulate existing perforations and eliminate the need for additional stimulation techniques, thus resulting in significant cost savings. It also adds that the technology can:

- Break down scale in the wellbore.

- Displace fines from gravel-pack screens.

- Break down asphaltenes and other plugging agents in heavy oil wells.

Unocal job

Unocal's well initially was completed with 300 ft of open perforations in the low-permeability Big Hum D formation. Expro said production rates and pressures in the wells steadily decreased over time and large diameter tubing hindered the well's natural lifting capabilities. Over time, the well could not produce against the 500-psi system.

To eliminate water and sand production, Unocal isolated the bottom 138 ft of perforations and left 162 ft of perforations open to flow.

Expro said this successfully eliminated water and sand production but did not initiate stable flow. Wellhead pressure would build readily to 1,500 psi. when shut-in but when brought online the pressure would drop to below line pressure in a matter of minutes.

Unocal, therefore, decided to stimulate the well to re-establish flow from this low-permeability interval and it contracted Expro services. To evaluate the well, Expro ran a gamma-ray, casing collar locator, pressure and temperature gauge survey on its slick line depth correlation system.

Based on the original log data and the Expro simulation runs, Unocal selected the best zones to stimulate. It chose to run three 15-ft StimTube assemblies and treat 75 ft of total interval.

Expro said that it observed an immediate pressure increase of 90 psi at the surface upon detonation of the first tube assembly. Pressure increased another 20 psi after the second firing.

A total 120 psi increase was observed in surface pressures over the three runs, according to Expro.

At this point, the well was brought online and produced at stable flow rates.

Murray E. Gardin, Unocal Operations Engineer, said of the job, StimTube "allowed us to re-establish flow from this wellU Payout of our entire project occurred in less than 10 days."