New approach developed for estimating pour points of crude oil blends

Development of a viable crude transportation system that moves multiple crude oils requires knowledge of the crude blend pour points and other properties.

The pour points of crude blend are generally not linearly proportional to the mixing-ratio of every individual crude.

Reported approaches for estimating the pour points of crude blends require the pour points of every binary crude blend at a mixing-ratio of 1:1 or several compositional contents such as paraffin, resin, gas-benzene contents in the blends and viscosities at some temperatures. These requirements cause great difficulties in some cases when these basic data are unavailable as when, for example, no crude sample is available.

An analysis on pour-point data from 26 binary crude blends has revealed a good relationship between two differences of pour point:

- The difference between the measured and the linear-weighting-estimated pour points of the binary crude blends at a mixing-ratio of 1:1.

- The difference between the pour points of the two individual crudes.

This analysis has permitted development of a new correlation for estimating the pour points of multiple crude blends. Use of this correlation allows estimation of the pour points of multiple crude blends at any mixing-ratio by use of only the pour points of the individual crudes.

Verified by experimental data of multiple crude blends from two to five individual crudes, the new approach has equivalent accuracy compared to the reported approaches and presents a new way to estimate the pour points of any multiple crude blends.

Waxy-crude pipelining

Pipeline transportation of multiple crude oils requires an insight into the properties of individual crudes and the blends.

The pour point, the lowest temperature at which movement of the specimen is observed under the condition of the test, is a key parameter for waxy crude pipelining.1

The pour points of the crude blends are often between the highest and the lowest pour points of the individual crudes.

But generally, the pour points are not linearly proportional to the mixing-ratio of each crude. There has been some reported success in estimating the pour point of crude blends (Equation 1 in the accompanying equations box).2-4

More recently, based on the regression analysis of related assay data for 55 crudes, another empirical equation (Equation 2) was put forward to estimate the pour points from crude properties.5

Equation 1 has found wide application in estimating pour points of crude blends in China. Good agreements have been achieved between estimated and measured pour points. Equation 2, as the authors stated, was only valid for the Northern Gateway Terminal System database with pour points measured by the procedures used by Arkhangelskgeologia, although it was believed that the general form of Equation 2 should be applicable where an extensive database was available.

For estimating the pour points of crude blends by using Equation 1, however, the pour points of every binary crude blend at a mixing-ratio of 1:1 are indispensable.

This causes great difficulties sometimes when crude samples required for determining 1:1 blend pour point are unavailable.

On the basis of analysis on a large amount of pour-point data, the new approach to estimating the pour point of crude blends at any mixing-ratio, independent of the pour point of the 1:1 binary crude blend, has been developed. With this approach, pour points of multiple crude blends at any mixing-ratio can also be predicted by only use of the pour points of individual crudes.

The result is a new way to estimate the pour points of crude blends, especially when the pour points of every binary crude blends at a mixing-ratio of 1:1 or crude blend properties and compositional contents, such as those required by Thomas and Thomason's correlation,5 are unavailable.

Estimating pour points

For binary crude blends, Equation 1 can be written as Equation 3.

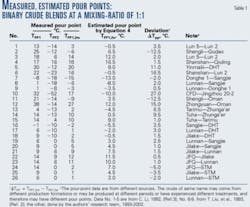

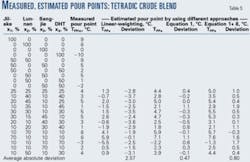

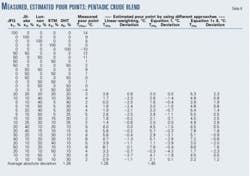

If TPP1,2 is unavailable, the crude blend pour point cannot be estimated with Equation 3 with the exception of assuming, C1,2=0 namely 2TPP1,2 = TPP1+TPP2 has to be adopted. Then Equation 3 becomes a linear-weighting equation (Equation 4). Previous work showed that the pour points of crude blends were generally not linearly proportional to the mixing-ratio of individual crude.2-4 Table 1 also shows that in some cases the linear-weighting equation presents large deviations. TPP1,2m in Table 1 is the measured pour point of the binary crude blend at a mixing-ratio of 1:1, while TPP1,2eis the estimated pour point by Equation 4.

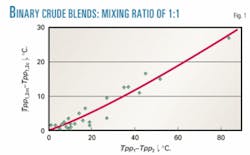

It can be seen from Table 1 and Fig.1 that there exists good correlativity between the following two differences of pour points: the difference between the measured pour points and the estimated pour points by using Equation 4 and the differences among the measured pour points of individual crudes.

The relations can be expressed as shown in Equation 5. The correlation coefficient R2 for Equation 5 is 0.9164.

Equation 5 can be rewritten as Equation 6; use of Equation 6 will yield Equation 7.

As a result, use of Equations 3 and 7 allows estimation of the pour points of any binary crude blends at any mixing-ratio without the requirement of the 1:1 blend pour point.

Extending the correlation for binary crude blends to n-crude blends allows the Ci,k in Equation 1 to be rewritten as Equation 8.

According to Equations 1 and 8, the pour points of n-crude blends at any mixing-ratio can be estimated without the pour points of every 1:1 binary crude blend. When n = 2, Equation 8 reduces to Equation 7 for binary crude blends.

The pour points of crude blends vary with the mixing-ratio of individual crudes, and it was reported that the pour points of crude blends were very much dominated by the crude with the highest pour point.5 6 In most cases, the coefficient Ci,k in Equation 8 has a plus sign, especially for crude blends of high paraffinic crudes with less asphaltene content.3

On the contrary, if one crude in the binary blend is heavy crude characterized by high resin and asphaltene contents (such as the Shengli and STM crudes in Table 1), the coefficient (Ci,k) is most likely to have a minus sign. Obviously, a sign of plus is conservative in case the crude characteristics are not clear.

Verifications

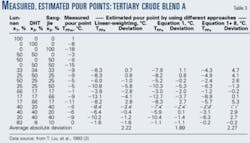

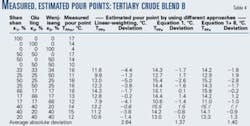

Five sets of pour-point data from blends of two to five crude oils were used to verify the newly developed approach. Three pour-point estimating approaches were employed: linear-weighting rule (Equation 3), Equation 1, and Equations 1 plus 8. (The Ci,k in Equation 1 was calculated with Equation 8.)

In estimating, the coefficient Bi,k in Equation 1 was calculated with the equation Bi,k=1-xi/2+xk/2, while Ci,k in Equation 8 adopted a plus sign except for that in Table 6 where C4,k (k=1, 2, 3, 5) adopted a minus sign because of the STM heavy crude.

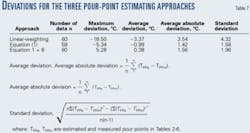

Tables 2-6 present the comparisons between the measured and estimated pour points for these binary to pentadic crude blends. The statistics of deviations for these three pour- point estimating approaches are shown in Table 7.

Tables 2-7 lead to the conclusion that the linear-weighting approach often bears large deviation and its accuracy varies from blends to blends; whereas the newly developed correlation has a statistically equivalent accuracy compared to the reported model (Equation 1), which however requires the pour point of binary crude blends at a mixing-ratio of 1:1.

Example application

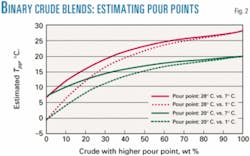

A subsea pipeline system transporting the blend of two crudes was to be designed for developing an offshore oilfield. Previously, pour points of the two individual crudes were determined: Crude A had pour point ranging 20º C. to 28º C.; Crude B had the pour point ranging from –1º C.-7º C. Unfortunately, the samples of the two crudes were no longer available. Therefore, the pour point of the binary crude blend at a mixing-ratio of 1:1 could not be determined experimentally.

As a result, Equation 1 was not applicable.

Using the newly developed approach allows the pour points of the blend at various mixing-ratio could be estimated (Fig. 2).

Because the pour points of the two individual crudes were in a range instead of certain values, ranges of crude blend pour point in different combinations of individual pour points could be obtained.

References

1. ASTM D97-87. Annual. ASTM Standard. 1989, 05.01.

2. Liu, T., Sun, W., Gao, Y.Q., Xu, C. Oil and Gas Storage and Transportation 18 (1999), Vol. 9 (in Chinese).

3. Liu, T., Zhang, X.J., Xu, C., Oil and Gas Storage and Transportation 12 (1993) Vol. 2 (in Chinese).

4. Li, C., Flow properties of multiple crude blends: experiments and correlations, M.Sc Thesis, University of Petroleum, China, 1992 (in Chinese).

5. Danielson, T.J., and Thomason, W.H., Influence of crude properties on Northern Gateway terminal transportation system, 3rd International Conference on Development of the Russian Arctic Offshore, Sept. 23-26, 1997.

6. Thomason, W.H., "Start-up and shut-in issues for subsea production of high paraffinic crudes," Offshore Technology Conference, Houston, May 1-4, 2000.

The authors:

Jun Chen ([email protected]) is a senior engineer with experience in petroleum engineering and petroleum storage and transportation engineering at the University of Petroleum, China. Chen holds a BSc (1988) and a MSc (1991) in petroleum engineering and a PhD (2003) in petroleum storage and transportation engineering from the University of Petroleum, China.

Jinjun Zhang ([email protected]) is a professor and the head of the department of petroleum storage and transportation, University of Petroleum China at Beijing. He holds a BSc (1982), MSc (1987), and PhD (1998) in petroleum storage and transportation from the University of Petroleum China and has 21 years' experience in research of crude oil rheology and pipeline transportation.

Fan Zhang is an associate professor of the department of petroleum storage and transportation, University of Petroleum, China at Beijing. He holds a BSc (1984) and an MSc (1995) in petroleum storage and transportation from the University of Petroleum China, and he is now a hydromechanics PhD candidate at the Chinese Academy of Sciences. Fan Zhang has 19 years of experience in research of crude oil rheology and pipeline transportation.