STRADDLE GAS PLANTS—Conclusion: Australia straddle plant's operating strategy mirrors Aux Sable

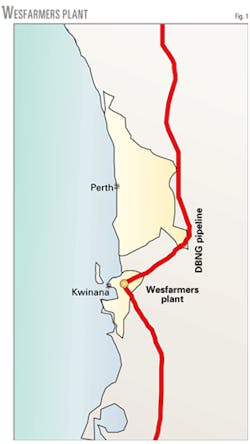

Wesfarmers Energy Ltd.'s (WEL) Kwinana, Western Australia, plant processes LPG combined with gas flowing in the Dampier-Bunbury natural gas pipeline (DBNGP) from producers on Australia's Northwest Shelf (NWS).

The circumstances in Western Australia (WA) resemble the Alliance-Aux Sable situation (OGJ, Jan. 6, 2003, p. 48), in which operators there can spike LPG into the gas stream to enhance naturally occurring gas constituents.

The WEL Kwinana plant supplies LPG to the local market in southwestern WA.

Part 1 of this four-part series examined the historical development of Alberta straddle plants; Part 2 provided a future outlook for those facilities.

Part 3 focused on two straddle plants that have on site fractionation. The Conoco Canada Midstream Empress straddle plant in southeastern Alberta supplies propane to local markets in Alberta, Saskatchewan, and Manitoba.

The Aux Sable Liquid Products LP (Aux Sable) plant near Chicago processes gas from the Western Canadian Sedimentary Basin that is delivered by the Alliance pipeline.

Aux Sable supplies propane and butane to markets in Illinois and adjacent states.

Kwinana NGL recovery

The WEL Kwinana plant (Fig. 1) can recover 330,000 tonnes/year (tpy) of LPG.1 It serves local markets and has a marine terminal and refrigerated storage for LPG export.

The other significant source of LPG in southwestern WA is BP PLC's refinery at Kwinana.

In addition to the conventional cylinder and bulk LPG market in southwestern WA, there are five pipeline systems for LPG distribution.2 These systems include Leinster and Margaret River, operated by Wesfarmers Kleenheat Gas Pty. Ltd., and The Vines and Albany, operated by AlintaGas Ltd.

WA gas, oil production

WA currently produces oil and gas and has significant reserves in the Perth and Carnarvon basins.

In 2001, WA gas utilization was approximately 0.7 tcf.3 Of this, 0.3 tcf was used within WA, and 0.4 tcf was converted to LNG for export to Japan and other countries.

Identified gas resources in WA include the Carnarvon basin with 64 tcf and the Browse basin with 35 tcf.3 The Canning and Bonaparte basins in WA also have prospective oil and gas resources (Fig. 2).

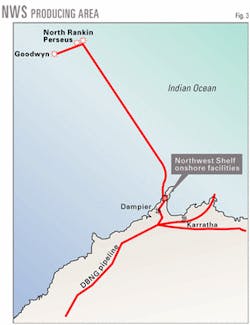

The NWS LNG plant, owned equally by six companies, produces more than 7.5 million tpy of LNG.3 The North Rankin field initially supplied all the gas feed for LNG production; however, the Goodwyn and Perseus fields now also provide feed gas (Fig. 3).

In May 2002, NWS LNG sellers announced an LNG expansion of 4.5 million tpy, which will come on stream in mid-2004.4

Onshore pipelines in WA

The WEL Kwinana plant sits adjacent the DBNGP, which is owned and operated by Epic Energy South Australia Pty. Ltd.

This system, commissioned in 1984, has 1,788 km of high-pressure transmission line and provides a firm capacity of about 500 MMcfd.

The DBNGP system serves many of the natural gas markets in the corridor from Dampier to Perth, as well as gas markets in Fremantle, Kwinana, and Bunbury.

The quality of gas flowing through DBNGP has been subject to public scrutiny.5-7

Unlike most gas processing situations in which LPG and NGL are recovered from gas, LPG is injected into the DBNGP to raise its content to 1.45 tonnes/terajoule. This contractual entitlement benefits WEL and AlintaGas.

NWS producers have set the LPG price based on its energy value.5 Circumstances in WA are analogous to Alliance-Aux Sable where producers receive gas value for the gas and any indigenous liquefiable constituents.

In the DBNGP, third-party shippers are required to supply gas with a minimum LPG content of 1.45 tonnes/terajoule or pay compensation.

Alliance does not impose any minimum LPG content obligation on its shippers; however, the Alliance volumetric toll provides an incentive to ship high-btu gas.

The DBNGP gas-quality issue has been the subject of public scrutiny because of the implicit requirement that the gas must be:

- Suitable for end-use appliances.

- Suitable for transport without pipeline-operating problems.

- Environmentally acceptable.

- Useable within safety and health constraints.

The LPG requirement restricts the quality of acceptable gas in the DBNGP.

In addition to an LPG-content requirement, the original WEL contract and DBNGP gas quality specification imposed a 5 mole % limit on total inerts.5

A November 1995 report5 stated that only 20% of known WA gas resources fell within the DBNGP gas quality specifications.

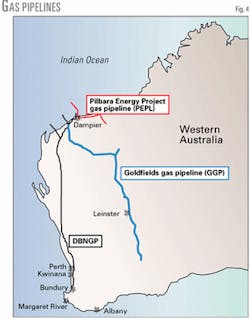

There are four other gas transmission systems in WA; these include the Goldfields Gas Pipeline (GGP) from the Canarvon basin to the Pilbara and Eastern Goldfields, and the Pilbara Energy Pipeline (PEP) from the Carnarvon basin to Port Hedland.

GGP and PEP mainly serve industrial markets and impose less-stringent gas quality specifications than DBNGP. Fig. 4 shows the routing of the DBNGP, GGP, and PEP systems.

NWS NGL recovery

The NWS partners own an 800,000-tpy processing plant and LPG export facility at Karratha, WA. The LPG is propane and butane.8

LPG is produced from the Wanaea, Cossack, Goodwyn, and North Rankin fields. Current propane and butane recovery levels at Karratha are approximately 10,500 b/d and 12,600 b/d, respectively.

Condensate production from gas recycling at the North Rankin A (NRA) platform is about 40,000 b/d,8 and the Goodwyn A (GWA) platform produces about 60,000 b/d.

The offshore gas pipelines are two phase, gas-liquid lines that operate at 2,060 psig.9

The pipeline from NRA to shore was built in 1982 and spans the 134 km from NRA to Withnell Bay. The connecting pipeline from GWA to NRA is 23 km long.

WA commercial challenge

The contract with the NWS Partners for LPG injection expires in 2005. This contract has been a lucrative source of earnings for AlintaGas.10

Contract termination would also adversely affect WEL, forcing it to close the Kwinana plant and convert the terminal into an import facility.

Termination of LPG injection would also change gas quality in the DBNGP. This could force AlintaGas and WA regulators to inspect and possibly replace old appliances that might be unsafe with a different gas quality.5

On several occasions, WEL indicated its willingness to find a commercial solution to ensure the continued availability of LPG to the Kwinana plant and markets in southwestern WA.

Comparison to North America

While there may be some similarities between WA and Alliance-Aux Sable, the two situations are not identical.

For Alliance and Aux Sable, any NGL or LPG that is injected into Alliance is usually bought and paid for as NGL or LPG. Aux Sable can earn a margin on injected material; recovered NGL or LPG is sold as specification product.

The Illinois and the US PADD II markets for propane and normal butane are seasonal (Part 3); therefore, there may only be an incentive to inject propane and butane into Alliance during the winter (PADD = Petroleum Administration District for Defense).

Alliance consumes natural gas as fuel at compressor stations but has no major deliveries upstream of Chicago. This contrasts with the significant upstream deliveries from DBNGP.

The Aux Sable operation ensures that gas delivered to downstream markets meets gas-quality requirements. In contrast, gas delivered by DBNGP must meet acceptable quality specifications in markets both upstream and downstream of Kwinana. This situation is analogous to the significant gas deliveries in Alberta, the quality of which must meet the required standards.

After the gas is processed in the straddle plants, it must also meet quality standards in the downstream markets.

LPG injection into DBNGP was likely intended as an economical way to move LPG to southwestern WA. Although this reasoning was also true for the Alliance pipeline, the main driver for Alliance was the enhancement of gas-flow characteristics that were outlined in a Canadian patent.11

This patent is applicable at pressures greater than 1,000 psia. The patent asserts, "At pressures over 1,000 psia, it is advantageous to addUan additive which is a C2 or C3 hydrocarbon or a mixture of such additives.

Above a lower limit, this results in a smaller product of the z factor times the molecular weight of the gas than would exist with methane alone, therefore leading to a decrease in the amount of power needed to pump the mixture or to compress it."

An Australian patent was recently granted for the same invention.12 The "z-factor" is the gas compressibility factor.

References

- Browning, Bob, "AlintaGas – We've Built A Strong Foundation," presentation to shareholders, AlintaGas Ltd., Perth, May 9, 2002.

- "Regional Gas Reticulation – Discussion Paper," Western Australia Office of Energy, Perth, 2002.

- "Western Australian Oil and Gas Industry, July 2002," Department of Mineral and Petroleum Resources, Government of Western Australia.

- "Northwest Shelf signs LNG sales and purchase agreement," press release, Woodside Energy Ltd., Perth, May 29, 2002.

- "Review of the Gas Quality Specification for the Dampier to Bunbury Natural Gas Pipeline in Western Australia," Western Australia Office of Energy, Perth, November 1995.

- Hawkins, David J., "Report on Overseas Experience for Industry Forum on the Quality Specifications for the Transmission of Natural Gas in Western Australia," Energy Policy and Planning Bureau, Perth, July 15, 1994.

- Hawkins, David J., "Report on Industry Submissions for Industry Forum on the Quality Specifications for the Transmission of Natural Gas in Western Australia," Energy Policy and Planning Bureau, Perth, July 15, 1994.

- "Products and Customers," Woodside facts sheet, Woodside Australian Energy, Perth.

- "Support Facilities," Woodside facts sheet, Woodside Australian Energy, Perth.

- "LPG shift could cost AlintaGas lucrative contract," Australian Financial Review, Nov. 7, 2002, p. 22.

- Morris, Ian, and Perry, Glen, "Pipeline Transmission Method," Canadian Patent 2205670, Nov. 18, 1996.

- Morris, Ian, and Perry, Glen, "Pipeline Transmission Method," Australian Patent 747206, Apr. 16, 1998.