Equipment/Software/Literature

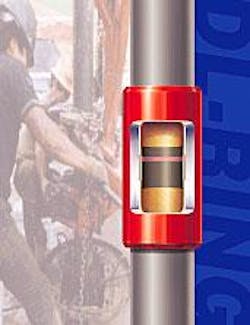

Corrosion barrier ring aids oil country tubulars

DL-Ring, a patent-pending connection technology, permits the lining system to accommodate any tubing and casing proprietary shoulder-to-shoulder "premium connector."

This corrosion barrier ring enables placement of internal liners within any unmodified shoulder-to-shoulder premium thread without the need for a special coupling.

Used in conjunction with DUOLINE, this firm's premium internal corrosion resistant lining system for oil field steel tubing and line pipe, helps solve problems beginning with a capability for joining a range of pipe that traditionally required custom designed solutions.

DUOLINE has proved to be wireline abrasion and chemical resistant. It has been used with high quality performance in controlled testing of more than 70 million ft of field downhole well interventions, the company says.

With the additional use of the DL-Ring, two composite-molded GRE end flares are used to place the T-shaped PTFE DL-Ring into compression during field makeup.

Source: Rice Engineering Corp., 9019 N. Co. Rd. West, Odessa, TX 79764.

New stuffing boxes offer reliable sealing

New Hercules Big Stuff DPSB stuffing boxes offer reliable sealing under a variety of operating conditions.

They provide an easy-to-adjust threaded cap with no bolts to tighten and allows the main packing to be changed under pressure by tightening compression bolts.

The standard unit is rated at 1,500 psi working pressure and features two 1/4 in. NPT ports (180° apart) for grease zerk and pressure gauge.

Stuffing boxes are available with inverted cone or DOME packing and also offer protection of packing from the weight of the rod string.

Features include:

- Patented design.

- Selection of packing designs and materials.

- Corrosion resistant materials and coatings.

- Parts interchangeability.

- NACE option (2,500 psi working pressure.)

- Selection of accessories.

- Fail-safe environmental system.

- Field service and training.

Source: R&M Energy Systems, 363 N. Sam Houston Parkway, Suite 950, Houston, TX 77060.

Pump offers versatility, performance

The Moyno 1000 positive displacement pump promises versatility and performance.

It is engineered for trouble-free operation in a variety of services including shear sensitive chemical feeds and viscous fluid crude oil transfer applications. The pin-type universal joint is sealed and lubricated for long life and minimum maintenance.

Its two-piece drive shaft allows easy assembly, maintenance, and mechanical seal access.

This drive shaft configuration eliminates the need for complete pump disassembly when servicing the mechanical seal.

Additional features include:

- Low shear pumping action.

- Smooth, nonpulsating flow.

- Flow rates of 0.38-320 gpm.

- Pressure capabilities to 350 psi.

Source: Moyno Inc., Box 960, Springfield, OH 45501.

Fastening system works offshore, petrochem plants

Here's the X-BT Fastening System, which is designed specifically for offshore as well as petrochemical plant operations.

It's a way to fasten to prepainted steel without damaging the protective coating on either side of the base material. It's designed to work on construction steels as thin as 8 mm (5/16 in.).

Based on the DX powder actuated fastening principle, X-BT is made of A4/AISI 316 high grade stainless steel for long life and has a durable sealing washer.

The special flat tip is designed to avoid through-penetration of the base material. During the driving process, the washer forms a permanent seal around the entry point.

The system supports a range of uses such as fastening grating, cable connectors (Tbars), lighting, cable trays, junction boxes, instrumentation, and pipe hangers.

The company says a single user can set more than 100 studs in an hour; no rework involved.

Driving the flat tip of the X-BT stud into the predrilled hole creates a true weld by friction, capable of providing pullout values comparable with those found in stud welding, the firm notes. The combination of tools makes the system fully portable.

Source: Hilti Inc., 5400 S. 122nd E. Ave., Tulsa, OK 74146.